Understanding the Role of Electrical PVC Tape Manufacturers

Electrical PVC tape plays a crucial role in a wide array of electrical applications. As the backbone for ensuring safety and efficiency in electrical installations, the quality of this tape is largely determined by the manufacturers that produce it. This article explores the significance of electrical PVC tape manufacturers, the processes involved in its production, and the criteria for selecting a reliable manufacturer.

The Importance of Electrical PVC Tape

Electrical PVC tape, often referred to as insulating tape, is utilized for insulation, protection, and bundling of electrical wires and components. Its primary functions include electrical insulation, mechanical protection, and providing safety in electrical applications. It is resistant to moisture, UV light, and chemicals, making it ideal for both indoor and outdoor projects. The versatility and reliability of this tape make it an indispensable tool for electricians, maintenance workers, and DIY enthusiasts alike.

Manufacturing Process

The production of electrical PVC tape involves several stages, from selecting high-quality raw materials to adhering to strict industry standards. The primary component is polyvinyl chloride (PVC), which is chosen for its robust insulating properties. Manufacturers often add plasticizers to enhance flexibility and durability.

1. Material Sourcing Quality tape begins with high-grade PVC materials. Responsible manufacturers ensure that their materials are sourced ethically and comply with safety regulations.

2. Compounding In this stage, the PVC is mixed with various additives to achieve specific properties such as flexibility, heat resistance, and adhesive quality. This compounding process is critical in determining the tape's overall performance.

3. Film Extrusion The compounding mix is then extruded into thin sheets of PVC film. This film forms the base of the electrical tape and is produced to meet various thickness requirements.

4. Coating A layer of adhesive is applied to the PVC film to ensure it sticks properly when wrapped around electrical wires. The adhesive used must be strong enough to withstand high temperatures and humidity.

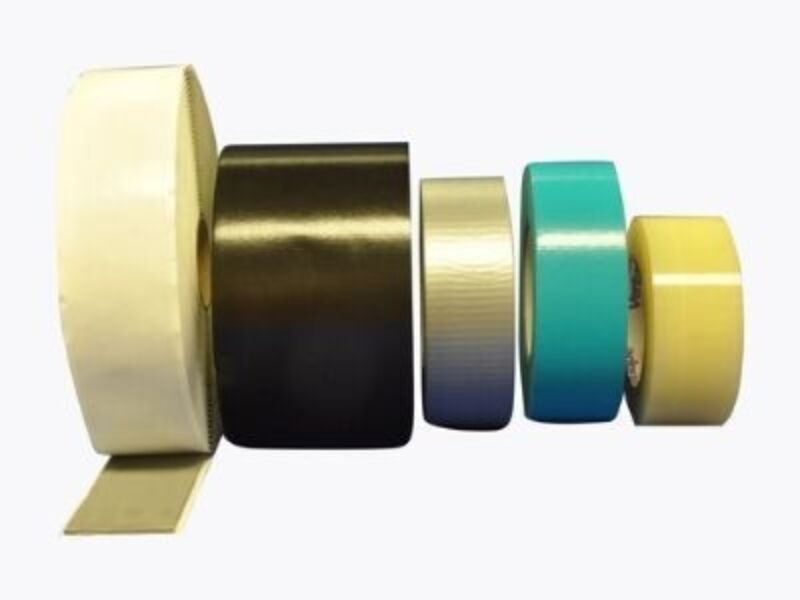

electrical pvc tape manufacturers

6. Quality Control Reputable manufacturers conduct rigorous quality control tests at every stage of production. These tests ensure that the tape meets international standards, such as ASTM, UL, and IEC certifications.

Selecting a Reliable Manufacturer

With numerous electrical PVC tape manufacturers available, selecting the right one can be daunting. Here are some key considerations

1. Reputation and Experience Established manufacturers with years of experience tend to produce higher-quality products. Researching customer reviews and case studies can provide insight into their reliability.

2. Quality Assurance Ensure the manufacturer has a solid quality management system in place. Certifications such as ISO 9001 indicate a commitment to maintaining high production standards.

3. Product Range A good manufacturer should offer a variety of electrical PVC tapes catering to different applications—such as high temperature, low temperature, and colored tapes. This flexibility can help you find the right product for your needs.

4. Customization Options Some manufacturers provide custom solutions to meet specific requirements. If your project demands unique specifications, working with a manufacturer that offers customization can be beneficial.

5. Customer Support Reliable manufacturers prioritize customer service. They should be open to answering queries and providing technical support as needed.

6. Sustainability Practices In today’s eco-conscious market, it is important to consider manufacturers that follow sustainable practices. Look for companies that use recyclable materials and environmentally friendly production methods.

Conclusion

Electrical PVC tape is an essential component in the world of electrical wiring and insulation. As such, the quality of this tape directly correlates with the reliability of the electrical systems it protects. By understanding the manufacturing process and carefully selecting credible manufacturers, consumers can ensure they are using superior products that contribute to safe and efficient electrical installations. Whether for commercial or personal projects, investing in quality electrical PVC tape is a step toward ensuring long-lasting results and the utmost safety in electrical applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025