Understanding Electrical Rubber Splicing Tape A Comprehensive Overview

Electrical rubber splicing tape is a vital tool in the world of electrical repairs and installations. Its primary function is to insulate, protect, and splice electrical wires, making it an essential component in both residential and commercial applications. This type of tape is designed to withstand various environmental factors, ensuring durability and reliability.

One of the standout features of electrical rubber splicing tape is its elasticity. Unlike traditional electrical tapes, splicing tape is made from a rubber-based material that allows it to stretch while adhering securely to irregular surfaces. This characteristic is particularly beneficial when working with wires of different sizes and shapes, as it provides a snug fit that enhances insulation.

The adhesive quality of rubber splicing tape is also noteworthy. It typically uses a pressure-sensitive adhesive that bonds effectively to metal and plastic surfaces, ensuring that it stays in place even under challenging conditions. This is crucial for preventing electrical leakage and protecting against short circuits, which can lead to safety hazards and equipment failure.

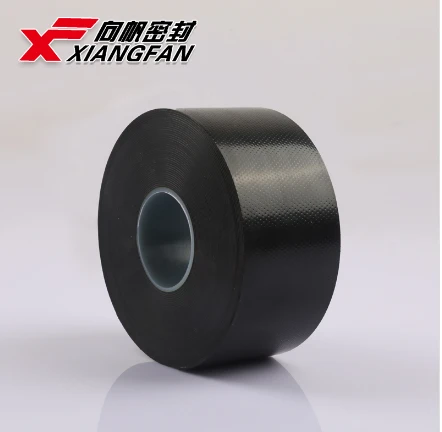

electrical rubber splicing tape

In addition to its excellent insulating properties, electrical rubber splicing tape is resistant to moisture, chemicals, and UV exposure

. This resistance makes it suitable for outdoor applications and environments where exposure to harsh elements is a concern. Whether it's in a residential setting, on a construction site, or in industrial use, this tape serves as a protective barrier that helps maintain the integrity of electrical systems.When applying electrical rubber splicing tape, several best practices should be observed. It is essential to start with a clean, dry surface to ensure maximum adhesion. Begin by wrapping the tape around the splice or connection, overlapping each layer by about half the width of the tape. This overlapping technique is crucial as it increases the insulation thickness and enhances waterproofing. The tape should be applied under tension to ensure that it adheres properly and forms a solid, protective layer around the wires.

Moreover, the use of electrical rubber splicing tape is not limited to splicing wires. It can also be employed for repair work, bundling cables, and even as a temporary fix for damaged insulation. Its versatility makes it a valuable addition to any electrician's toolkit.

In conclusion, electrical rubber splicing tape is a robust and reliable solution for maintaining electrical safety and integrity. Its unique properties, including elasticity, strong adhesion, and resistance to environmental damage, make it indispensable for various applications. Whether you’re an electrician or a DIY enthusiast, having electrical rubber splicing tape on hand can help ensure that your electrical connections are secure and insulated, providing peace of mind in your electrical projects. By understanding its properties and proper application techniques, users can enhance the longevity and safety of their electrical installations.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025