The Versatility and Importance of Electrical Rubber Tape

In today's world, where electrical systems are pivotal to everyday life, ensuring the integrity and safety of these systems is crucial. One unsung hero in the realm of electrical insulation and protection is electrical rubber tape. This specialized tape is not just a simple adhesive strip; it represents a blend of functionality, versatility, and safety that is essential in various electrical applications.

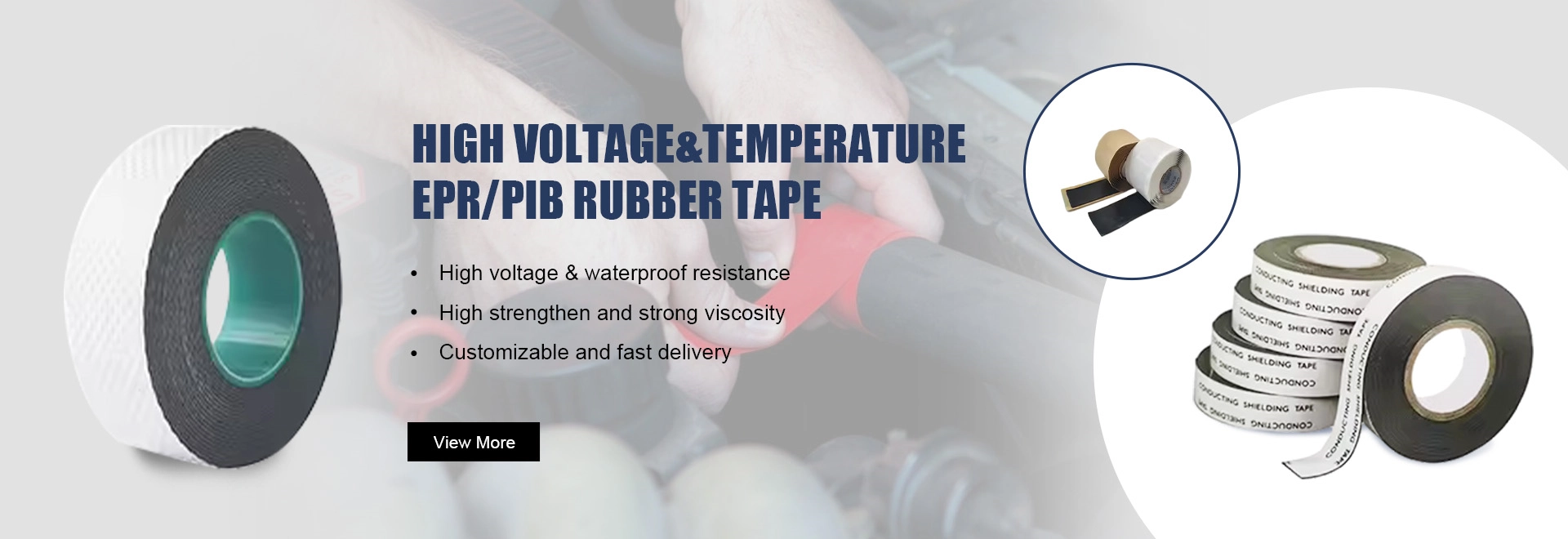

Electrical rubber tape is made from a blend of high-quality synthetic rubber compounds. This composition allows the tape to offer excellent insulation properties and resistance to heat, moisture, and various environmental factors. Its flexibility and stretchability enable it to conform to different surfaces and shapes, making it suitable for a wide range of applications, from household wiring repairs to industrial electrical installations.

One of the key features of electrical rubber tape is its ability to provide superior electrical insulation. This is vital in preventing short circuits, electrical shocks, and fires caused by exposed wires or damaged insulation. The tape effectively wraps around electrical connections, ensuring that no part of the conductor is exposed to the environment, thereby reducing the risk of accidents. For instance, when dealing with frayed wires or damaged insulation in appliances, wrapping the affected area with electrical tape can extend the life of the device and enhance safety.

Moreover, electrical rubber tape plays a critical role in moisture sealing. In environments where electrical components are subjected to water exposure or high humidity, such as outdoor lighting fixtures, the tape’s ability to create a waterproof barrier is invaluable. By sealing electrical connections and junction boxes, electrical rubber tape prevents corrosion and deterioration, ensuring that electrical systems remain operational even in challenging conditions.

electrical rubber tape

One of the most compelling advantages of electrical rubber tape is its ease of use. It is lightweight, easy to handle, and can be torn with bare hands, making it accessible for both professionals and DIY enthusiasts. Whether you are addressing a simple wiring issue at home or undertaking a complex electrical project in an industrial setting, electrical rubber tape can be applied quickly and efficiently, allowing for speedy repairs with minimal downtime.

In addition to its insulation properties, electrical rubber tape comes in various colors, aiding in the identification and organization of electrical systems. For example, different colors can signify different circuits, voltages, or functions, making it easier for technicians to navigate complex wiring systems. This color-coding feature enhances both safety and efficiency during installation and maintenance tasks.

When selecting electrical rubber tape, it is essential to consider factors such as thickness, temperature resistance, and adhesive strength. Quality products typically offer a longer lifespan, ensuring that the tape withstands wear and tear over time. Additionally, some tapes feature UL (Underwriters Laboratories) approval, indicating that they meet safety and performance standards.

In conclusion, electrical rubber tape is an indispensable tool in the world of electrical maintenance and installation. Its superior insulation, moisture resistance, ease of use, and organizational benefits make it a staple for professionals and homeowners alike. Whether you are making repairs, conducting installations, or simply securing electrical connections, investing in high-quality electrical rubber tape is a decision that prioritizes safety and reliability. In an age where electricity powers nearly every aspect of our lives, having the right tools to manage and protect these systems is more critical than ever.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025