The Importance of Electrical Splicing Tape in Electrical Applications

Electrical splicing tape is a specialized adhesive tape designed primarily for use in electrical applications. Its unique properties make it an essential tool for electricians, engineers, and DIY enthusiasts alike. This article explores what electrical splicing tape is, its benefits, applications, and best practices for use.

What is Electrical Splicing Tape?

Electrical splicing tape is typically made from a stretchy, rubber-based material that is resistant to moisture, heat, and electrical conductivity. Unlike standard adhesive tapes, it does not have a sticky backing but rather adheres to itself when wrapped around a surface. This feature allows users to create a solid and durable insulation barrier without leaving behind residue or compromising the integrity of the wires being spliced.

Benefits of Electrical Splicing Tape

1. Insulation The primary function of electrical splicing tape is to provide insulation. It can safely cover electrical connections and prevent accidental shorts, enabling the safe operation of electrical systems.

2. Durability Electrical splicing tapes are designed to withstand harsh conditions, including extreme temperatures and moisture. This durability ensures that connections remain secure over time, even in challenging environments.

3. Flexibility The tape is stretchy and conformable, allowing it to wrap around irregular shapes and surfaces easily. This flexibility makes it an ideal choice for splicing wires of different sizes and configurations.

4. Self-adhesive Since it adheres to itself rather than the surfaces it covers, electrical splicing tape can easily be applied and removed without damaging wires or components. This property facilitates easy repairs and modifications.

5. Versatility Electrical splicing tape can be used for a variety of tasks beyond electrical insulation, including bundling wires, fastening cables, and even marking or color-coding different connections.

Applications of Electrical Splicing Tape

Electrical splicing tape is widely used across various industries, including construction, automotive, telecommunications, and household wiring. Here are some common applications

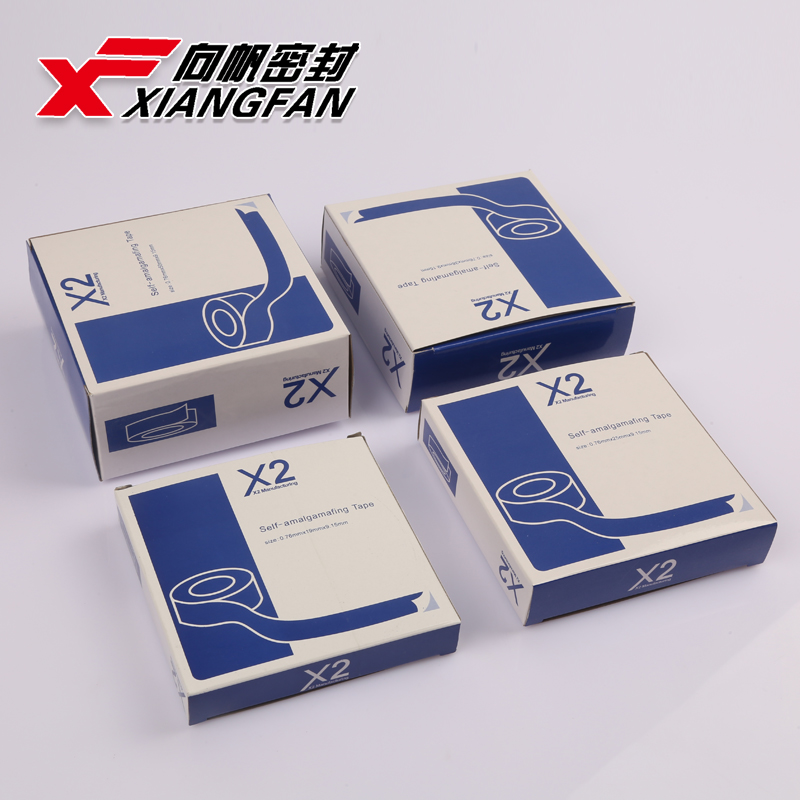

electrical splicing tape

- Wire Splicing When connecting two or more electrical wires, splicing tape is often used to cover the bare connections securely. It ensures that the exposed wires are insulated from their surroundings.

- Insulation Jacket Repair If the insulation on a wire becomes damaged, splicing tape can be applied to restore the insulation integrity, preventing electrical leakage and protecting against environmental factors.

- Bundling Wires For neat and organized installations, splicing tape can bundle multiple wires together to reduce clutter and improve aesthetics.

- Color Coding Electricians often use colored splicing tape to identify different circuits or connections easily. This method improves safety and efficiency, particularly in complex systems.

Best Practices for Using Electrical Splicing Tape

To maximize the effectiveness of electrical splicing tape, it is important to follow some best practices

1. Clean the surface Before applying the tape, ensure that the surface is clean and dry. Any dirt, oil, or moisture can hinder adhesion and reduce the effectiveness of the insulation.

2. Stretch the tape When applying the tape, stretch it slightly as you wrap it around the wires. This tension will help create a tight seal and secure insulation.

3. Overlap Layers When covering large areas or multiple layers, overlap the tape by about half of its width. This overlapping technique ensures complete coverage and enhances insulation.

4. Use appropriate width Select the right width of the splicing tape based on the size of the wires or connections. Wider tape may be more appropriate for larger installations, while narrower tape can be utilized for tighter spaces.

In conclusion, electrical splicing tape is a key component in electrical work. Its unique properties, such as insulation, durability, and flexibility, make it indispensable for ensuring safe and reliable electrical connections. By understanding its benefits and best practices, users can effectively leverage this tool to enhance their electrical projects. Whether in a professional setting or a DIY approach, electrical splicing tape plays a vital role in electrical safety and efficiency.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025