The Importance of Electrical Splicing Tape in Modern Electrical Systems

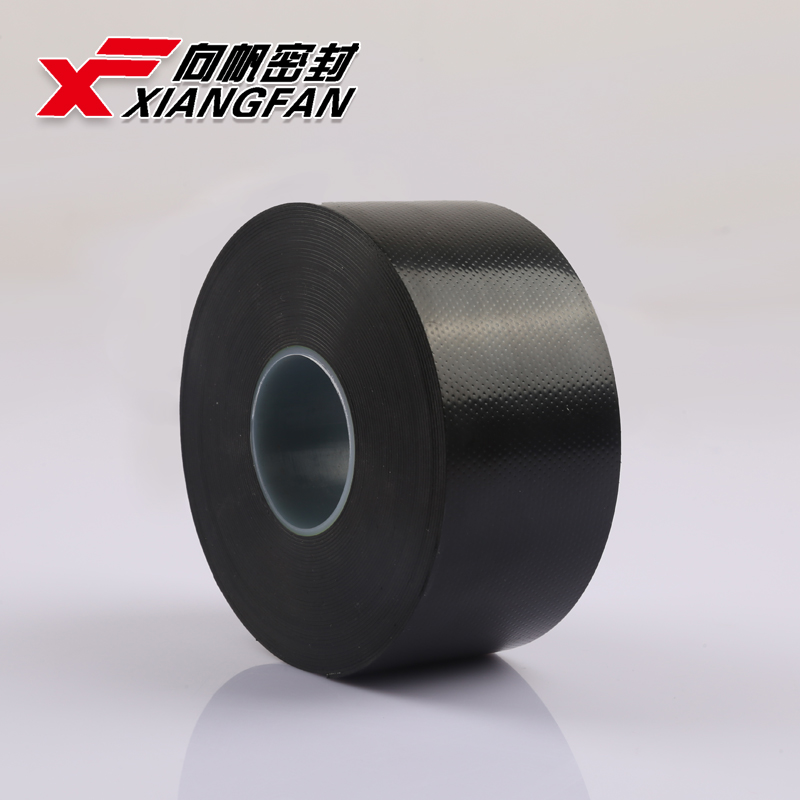

In an era where electrical systems play an integral role in our daily lives, the demand for safe and effective means of maintaining and protecting these systems is paramount. One such essential tool that has emerged in this domain is electrical splicing tape. This specialized type of adhesive tape is designed to insulate and secure electrical wire connections, providing a reliable solution for both amateur DIY enthusiasts and seasoned professionals in the electrical industry.

Understanding Electrical Splicing Tape

Electrical splicing tape is a non-adhesive tape made from PVC or rubber, often referred to as self-fusing tape. Unlike conventional adhesive tapes, which can lose their stickiness over time or under challenging environmental conditions, electrical splicing tape adheres to itself, forming a waterproof and airtight seal. This unique property makes it particularly effective in protecting electrical connections from moisture, dirt, and other contaminants that could potentially lead to short circuits or electrical failures.

Types and Applications

Several types of electrical splicing tapes are available on the market, each designed for specific applications. The most common types include

1. Standard Electrical Tape Usually made of PVC, this tape is ideal for insulating wires and can handle typical electrical applications. It is another popular choice for electrical splicing but may not be suitable for high-stress environments.

2. High-Voltage Electrical Tape Used primarily in industrial settings, this tape can withstand higher voltages and is often required for splicing high-voltage cables.

3. Self-Fusing Silicone Tape This high-performance tape fuses to itself when wrapped under tension. It is perfect for creating seals that can withstand extreme temperatures, making it suitable for environments with varying climatic conditions.

The versatility of electrical splicing tape is evident in its wide range of applications

. It can be used in automotive wiring, residential electrical systems, industrial machinery, and even outdoor installations such as lighting and electrical boxes.Advantages of Using Electrical Splicing Tape

1. Weather Resistance One of the primary benefits of electrical splicing tape is its excellent resistance to weather conditions. Whether it is humidity, rain, or extreme temperatures, this tape provides a reliable barrier against the elements.

electrical splicing tape

2. Durability Electrical splicing tape is designed to be robust. It can withstand mechanical stress, vibrations, and exposure to chemicals, making it suitable for use in various environments.

3. Ease of Use Unlike traditional adhesives, which require significant drying time, electrical splicing tape can be applied quickly and easily. Users simply need to stretch and wrap the tape around the connection, ensuring it adheres to itself without leaving a sticky residue.

4. Safety The electrical insulating properties of this tape help prevent electrical shocks and short circuits, making it an essential component for maintaining safety in electrical applications.

5. Cost-Effectiveness While some may perceive splicing tape as an additional expense, its longevity and effectiveness often lead to significant savings over time, particularly in preventing costly electrical failures or repairs.

Best Practices for Using Electrical Splicing Tape

When using electrical splicing tape, several best practices should be followed to ensure optimal performance

- Surface Preparation Clean the surfaces where the tape will be applied to remove any dirt, grease, or moisture. This ensures a better bond and seal. - Application Technique Start wrapping the tape tightly around the splice, overlapping each turn by about half the width of the tape. This overlapping technique provides better insulation and protection.

- Stretch and Secure When using self-fusing tape, stretch it as you wrap to ensure that it fuses correctly. The tension creates a strong, waterproof seal.

- Thickness Consideration Use an appropriate number of layers based on the required insulation level. For high-voltage applications, additional layers will provide extra safety.

Conclusion

In conclusion, electrical splicing tape is an invaluable tool in modern electrical systems, offering a blend of safety, durability, and versatility. As electrical systems continue to evolve, the demand for reliable and effective means of ensuring their integrity will remain critical. Whether you are a professional electrician, a DIY homeowner, or someone with an interest in electrical work, understanding and utilizing electrical splicing tape effectively can help you ensure the longevity and safety of your electrical installations.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025