The Role of Electrical Tape Manufacturers in Modern Industry

Electrical tape, a vital component in various electrical and electronic applications, is often overlooked despite its importance. This versatile product is used to insulate, protect, and secure electrical connections, making it an essential tool for electricians, engineers, and DIY enthusiasts alike. The electrical tape manufacturing industry has evolved significantly, offering a wide range of tapes designed to meet specific needs. Let's delve into the role of electrical tape manufacturers and the factors that influence their operations.

Manufacturing Process

The manufacturing process of electrical tape involves several stages, starting from raw material selection to production and quality control. Typically, electrical tape is made from a flexible polyvinyl chloride (PVC) backing, which provides excellent insulation and durability. The adhesive used on one side of the tape is specially formulated to ensure strong adhesion, even in extreme temperatures.

1. Raw Materials Manufacturers begin with high-quality PVC films and adhesives. The selection of these materials is crucial because the tape must withstand varying environmental conditions without losing its insulating properties. 2. Coating and Lamination The raw PVC film is coated with an adhesive layer. This process requires precision to ensure uniform thickness and optimal adhesive strength.

3. Cutting and Packaging After the tape has been manufactured, it is rolled onto spindles and cut into various sizes. Packaging is also an important aspect of the manufacturing process, as it must protect the tape from damage while ensuring ease of use for consumers.

4. Quality Control Stringent quality control checks are essential throughout the manufacturing process to ensure that the final product meets industry standards and customer expectations. This may involve testing the tape's thickness, adhesion, and resistance to temperature and chemicals.

Market Trends

The electrical tape market has seen significant growth due to advancements in technology and increased demand for better insulation solutions. Several trends are shaping the future of electrical tape manufacturing

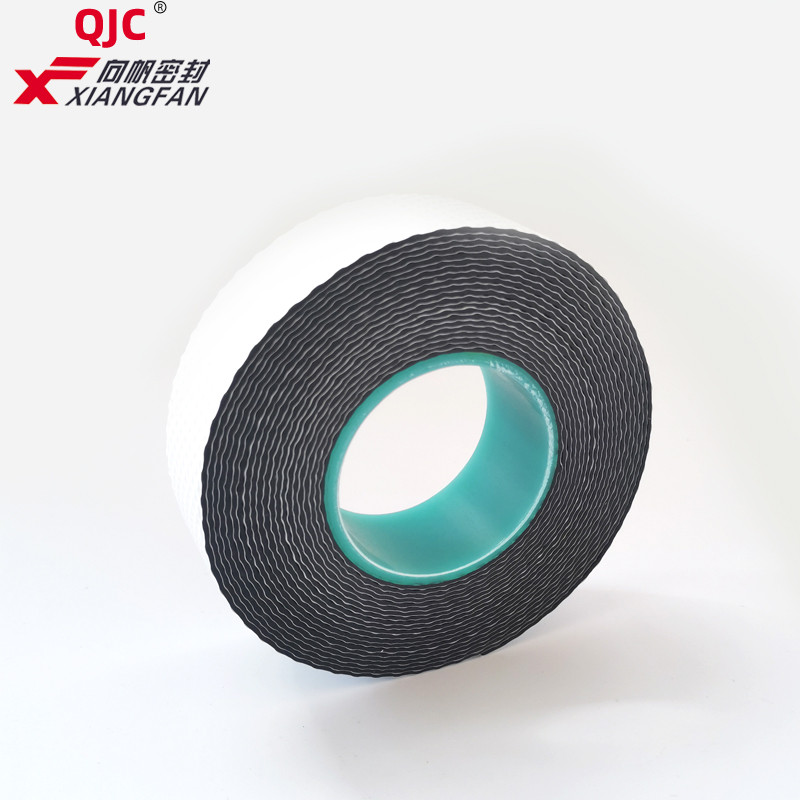

electrical tape manufacturers

1. Sustainability With growing environmental concerns, manufacturers are focusing on producing eco-friendly electrical tapes. This includes using biodegradable materials and reducing waste in the production process.

2. Technology Integration The rise of smart homes and IoT devices has led to a demand for specialized electrical tapes that can withstand different electrical loads and environmental conditions. Manufacturers are increasingly investing in R&D to develop tapes that cater to these emerging technologies.

3. Customization Different industries have unique requirements, leading to a rise in customized solutions. Manufacturers are now offering tailored electrical tapes that meet specific color codes, temperature ratings, and adhesive properties to suit different applications.

4. Globalization As industries expand globally, electrical tape manufacturers are adapting their products to meet international standards and satisfy diverse market needs. This globalization has led to increased competition but also opportunities for innovation.

Key Players in the Industry

Several leading manufacturers dominate the electrical tape market, each contributing to the industry's growth through their innovative products and practices. Companies like 3M, Avery Dennison, and Scapa have established a strong presence due to their commitment to quality and consumer satisfaction. These manufacturers often set industry benchmarks, pushing others to improve their offerings continually.

Conclusion

Electrical tape manufacturers play a significant role in the modern industrial landscape, providing essential products that ensure safety and efficiency in electrical applications. As the industry evolves, manufacturers must adapt to changing consumer needs, technological advancements, and environmental challenges. By focusing on sustainability, customization, and quality, electrical tape manufacturers will continue to thrive and support the growing demands of various industries. Their innovation and dedication not only enhance the functionality of electrical installations but also contribute to a safer and more reliable electrical infrastructure. As we move forward, the significance of electrical tape and its manufacturers will undoubtedly remain a cornerstone of electrical safety and efficiency in our connected world.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025