Understanding Expansion Joint Foam Strips Essential Components for Infrastructure Integrity

Expansion joint foam strips play a pivotal role in civil engineering and construction, serving as crucial components in various structures such as bridges, highways, and buildings. These foam strips are designed to accommodate the natural expansion and contraction of materials due to temperature fluctuations, ensuring structural integrity and longevity. In this article, we will delve into what expansion joint foam strips are, their benefits, applications, and installation processes.

What are Expansion Joint Foam Strips?

Expansion joint foam strips are flexible materials, often made from polyurethane or polyethylene foam, specially designed to fill the gaps or joints in various types of construction. These strips work on the principle of allowing movement while providing support and protection to the structure. They act as a buffer between different building materials, preventing damage caused by thermal expansion, seismic activity, or settling of the structure over time.

Benefits of Expansion Joint Foam Strips

1. Flexibility and Durability One of the primary advantages of using foam strips is their flexibility. They can absorb significant movements of the adjoining structures without cracking or failing, thereby enhancing the lifespan of the construction. The foam material is also resistant to moisture, chemicals, and UV radiation, ensuring that it remains effective in various environmental conditions.

2. Sound Insulation In addition to their primary function of accommodating movement, these foam strips can also aid in sound dampening. By filling gaps within structural joints, they reduce noise pollution, which is particularly beneficial in urban areas where sound levels can be a significant concern.

3. Cost-Effectiveness The installation of expansion joints with foam strips can be a cost-effective solution. By preventing structural damage due to expansion and contraction, these strips can save considerable repair and maintenance costs over time. Moreover, they are relatively easy to install, which can further reduce labor costs.

Applications of Expansion Joint Foam Strips

Expansion joint foam strips are utilized in various applications across different sectors

- Bridge Construction They are widely used in bridges to accommodate the frequent expansion and contraction caused by temperature changes, traffic loads, and environmental factors. This application is crucial as it enhances safety and ensures smooth traffic flow.

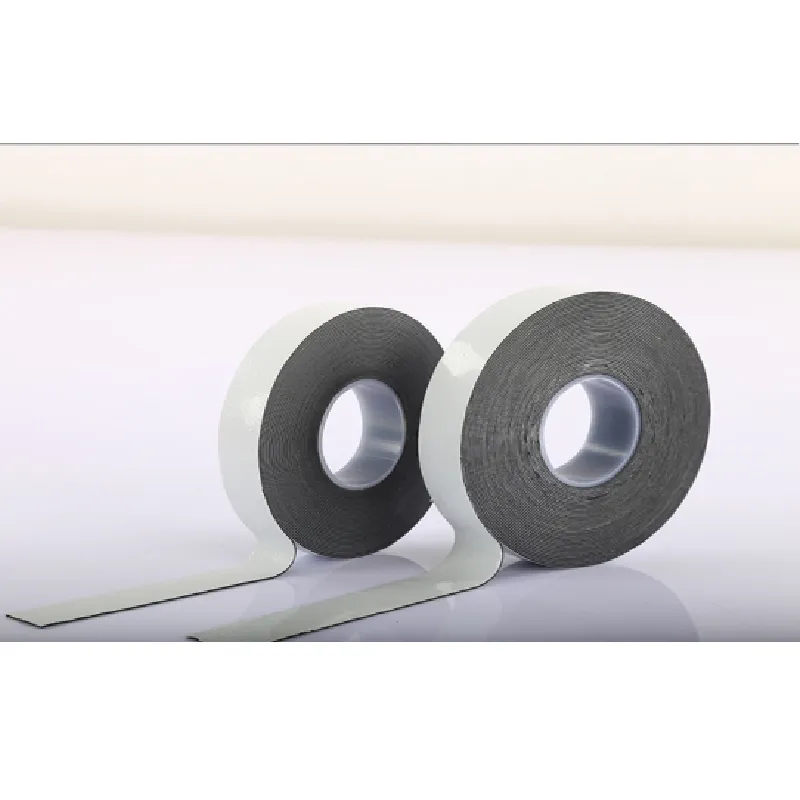

expansion joint foam strip

- Highways and Roads In highways, foam strips allow for the expansion and contraction of asphalt and concrete surfaces, thereby preventing cracking and surface failures that can worsen over time

.- Building Construction Within buildings, expansion joints are necessary in walls, floors, and roofs to manage movement due to settling, thermal expansion, and seismic activity. This is particularly important in multi-story structures where dynamic forces can lead to significant stresses.

- Manufacturing Facilities In industrial settings where machinery and materials undergo temperature changes, foam strips can help maintain structural integrity and prevent damage from vibrations and movements.

Installation Process

Installing expansion joint foam strips is a straightforward process but requires careful planning

1. Preparation The first step is to clean the area around the joint to remove any debris, dirt, or old sealant that may interfere with the foam strip's adhesion.

2. Sizing It is vital to measure the width and depth of the joint accurately to select the correct size of foam strip. The strip should fit snugly without being overly compressed.

3. Placement The foam strip is positioned into the joint, ensuring it is centered and correctly aligned. It is essential to leave enough space for the joint to expand and contract.

4. Sealing Finally, a sealant is often applied over the foam strip to protect it from moisture and enhance its durability.

Conclusion

Expansion joint foam strips are a key element in modern construction and infrastructure development. Their ability to mitigate the effects of thermal expansion, sound insulation properties, and overall durability make them indispensable in maintaining the integrity and longevity of a variety of structures. As we continue to face environmental challenges and climate change, the importance of such materials in our built environment cannot be overstated. Investing in quality expansion joint solutions is critical for ensuring the safety and durability of infrastructure for generations to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025