Understanding the Different Types of Insulation Tape

Insulation tape is an essential component in electrical and various other applications, acting as a protective layer against moisture, dust, and electrical conductivity. Understanding the various types of insulation tape can help you choose the right one for your specific needs. Here’s a comprehensive overview of the most common types of insulation tape available in the market today.

1. PVC Insulation Tape

PVC (Polyvinyl Chloride) insulation tape is one of the most widely used types of insulation tape. It is known for its excellent electrical insulation properties, durability, and resistance to abrasion and moisture. PVC tape is often used in electrical work for insulating wires and connectors. It's also available in various colors, making it ideal for color-coding electrical circuits. Its flexibility and ease of use make it suitable for both residential and commercial applications.

2. Vinyl Insulation Tape

Similar to PVC tape, vinyl insulation tape is popular for electrical insulation. It is made from a vinyl polymer and has excellent resistance to wear, UV rays, and aging. This type of tape is particularly beneficial in environments exposed to various weather conditions. Vinyl insulation tape is also known for its ability to conform to irregular surfaces, ensuring a snug fit, which enhances its insulating properties.

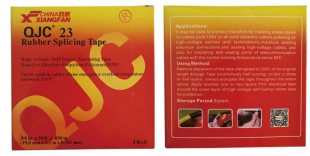

Rubber insulation tape is designed for applications requiring high resistance to heat and moisture. This type of tape is often used in high-voltage applications and is known for its excellent adhesive qualities. Rubber tape is typically used for splicing wires and providing insulation in electrical applications. Its ability to withstand extreme temperatures means it can be utilized in both outdoor and indoor settings, making it a versatile solution for electricians.

insulation tape types

4. Foam Insulation Tape

Foam insulation tape is primarily used for insulation in HVAC systems and building construction. This type of tape is often made from EPDM or other synthetic foam materials, which provide excellent thermal insulation. Foam insulation tape can help prevent heat loss and gain, making it an energy-efficient choice. It can also soundproof spaces, providing acoustic insulation in areas that require it, such as recording studios or home theaters.

5. Cloth Insulation Tape

Cloth insulation tape, also known as gaffer tape, has a fabric backing with a rubber adhesive. While it may not have as high an electrical insulation capacity as other types, it is often used for holding cables in place and securing equipment. Its flexibility and strength make it ideal for temporary solutions, especially in theatrical and production settings where rapid changes are required.

6. Mastic Insulation Tape

Mastic insulation tape is a type of self-fusing tape that is often used in industrial environments. It is thick and sticky, which allows it to create a robust seal against moisture and dust. Mastic tape is particularly beneficial for insulating cable joints and preventing corrosion in junction boxes. Its ability to form a tight, weatherproof seal means it is used in comprehensive outdoor installations, like power plants and telecommunications systems.

Conclusion

Choosing the right insulation tape depends on the specific requirements of your project. By understanding the different types, such as PVC, vinyl, rubber, foam, cloth, and mastic insulation tapes, you can select the appropriate tape that meets your needs in terms of insulation, adhesion, and durability. The right insulation tape will not only enhance the safety and efficiency of your electrical systems but also contribute to the longevity of the materials and equipment you are working with. As technology advances, it is essential to stay informed about the latest innovations in insulation tape to ensure you are using the best product available for your needs.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025