Exploring Self-Amalgamating Rubber Properties, Applications, and Benefits

Self-amalgamating rubber, also known as self-fusing or self-bonding rubber, is a remarkable material that has gained popularity across various industries due to its unique properties and versatile applications. This innovative type of rubber is designed to fuse to itself when pressed together, creating a seamless and watertight seal without the need for adhesives or additional bonding agents. This article delves into the characteristics, applications, and advantages of self-amalgamating rubber.

Properties of Self-Amalgamating Rubber

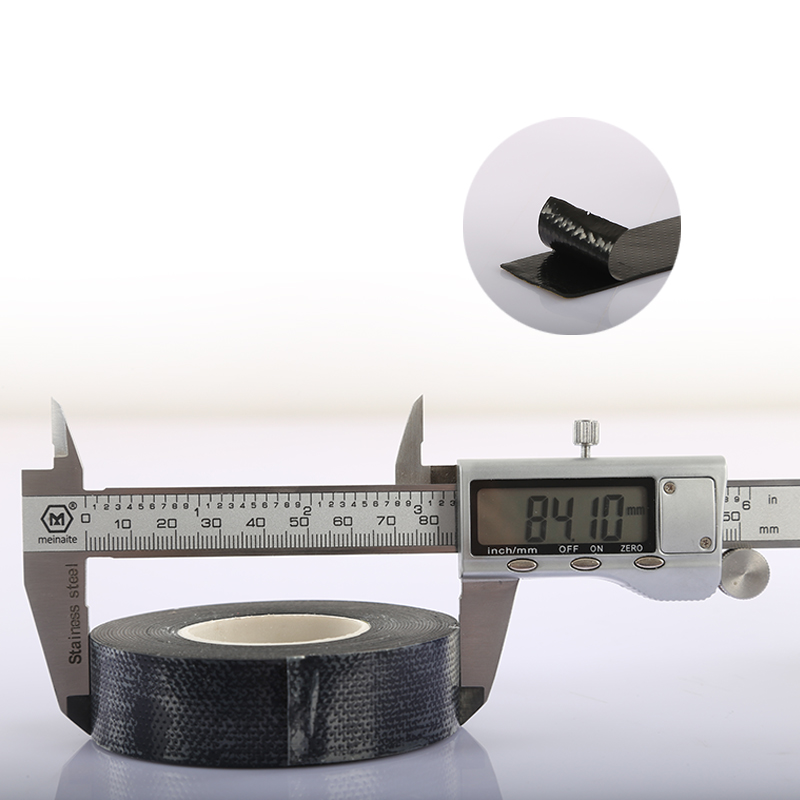

Self-amalgamating rubber is characterized by its high elasticity, flexibility, and resistance to environmental factors. Typically made of silicone, neoprene, or other synthetic rubbers, it showcases impressive resistance to chemicals, UV radiation, moisture, and extreme temperatures. These properties make it suitable for both indoor and outdoor applications. When the rubber is wrapped around a surface, it cures and merges with itself, forming a solid layer that is durable and long-lasting.

One of the most distinctive features of self-amalgamating rubber is its ability to provide a strong, insulating barrier once bonded. This characteristic is particularly beneficial for electrical applications, where insulation is critical for safety and performance. The rubber will not degrade over time, ensuring long-term protection against corrosion and electrical leakage.

Applications in Various Industries

The versatility of self-amalgamating rubber allows it to be employed in a wide range of applications across different sectors

1. Electrical and Electronics Self-amalgamating rubber is widely used in electrical installations for insulating wires and connections. Its ability to maintain electrical integrity while providing a moisture barrier makes it ideal for both commercial and residential electrical projects.

self amalgamating rubber

2. Automotive In the automotive industry, this rubber is utilized for sealing and protecting cables, hoses, and other components exposed to harsh conditions. Its excellent weather resistance ensures that vehicles remain protected from water, dust, and heat.

3. Construction In construction, self-amalgamating rubber can be utilized for waterproofing roofs and other structures. It is also employed in plumbing applications to repair leaks and seal connections due to its strong adhesive properties.

4. Aerospace and Marine The aerospace and marine industries utilize self-amalgamating rubber for its lightweight nature and resistance to extreme environmental factors. It is used to seal aircraft components and protect marine equipment from environmental wear.

5. Medical Field In the medical field, self-amalgamating rubber may be used in applications requiring sterile and secure sealing, such as in certain types of medical tubing connections.

Benefits of Self-Amalgamating Rubber

The advantages of using self-amalgamating rubber are numerous. Firstly, it eliminates the need for solvent-based adhesives, making it more environmentally friendly. Additionally, its ease of application allows for quick repairs and installations, saving time and labor costs.

Moreover, the durability and long lifespan of self-amalgamating rubber contribute to long-term savings for businesses and individuals alike. By effectively preventing leaks, electrical failures, and environmental damage, this material ensures reliability and reduces maintenance needs.

In conclusion, self-amalgamating rubber is a highly beneficial material that plays a crucial role in various industries. Its unique properties and capacity to form strong, lasting seals make it a preferred choice for insulating, sealing, and protecting a wide range of applications. As technology advances, the development of even more specialized forms of self-amalgamating rubber is likely to expand its applications further, establishing it as an essential material in contemporary manufacturing and construction processes.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025