Fiberglass Tape for Electrical Insulation A Comprehensive Overview

In the realm of electrical insulation, fiberglass tape has emerged as a vital component due to its exceptional properties and versatility. This type of tape, primarily composed of woven fiberglass, exhibits outstanding thermal resistance, mechanical strength, and electrical insulation capabilities, making it an indispensable material in various industrial applications.

One of the most significant advantages of fiberglass tape is its high-temperature resistance. It can typically withstand temperatures ranging from -40°C to 260°C (-40°F to 500°F), surpassing many conventional insulation materials. This feature is particularly beneficial in environments where electrical components generate substantial heat, as it helps prevent degradation and enhances the longevity of electrical systems. Moreover, fiberglass tape is also resistant to moisture and various chemicals, further solidifying its role in protecting electrical wiring from environmental stresses.

In addition to thermal and chemical resistance, fiberglass tape possesses excellent dielectric properties. This means that it acts as an effective insulator, preventing electrical current from unintentionally flowing where it shouldn't. This is crucial for ensuring safety in electrical applications, particularly in high-voltage scenarios where the risk of arcing or short circuits is significant. By utilizing fiberglass tape, manufacturers and electricians can minimize these risks and enhance the overall safety of their systems.

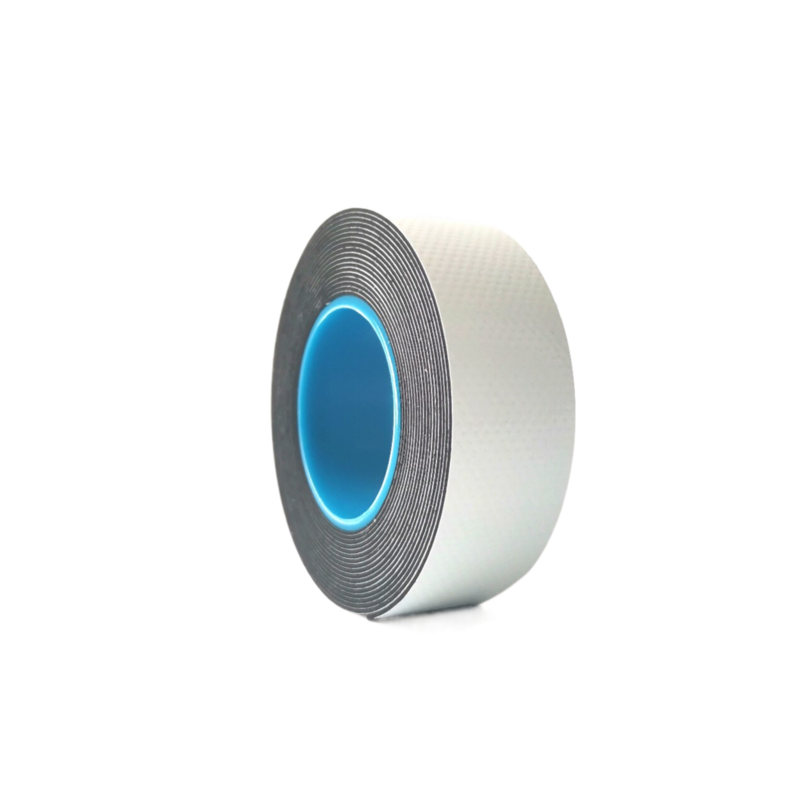

fiberglass tape for electrical insulation

Another important characteristic of fiberglass tape is its mechanical strength. The woven structure provides tensile strength, allowing the tape to endure tension and abrasion during installation and operation. This durability makes fiberglass tape suitable for a variety of applications, including wrapping around wires and cables, reinforcing connections, and securing electrical components in place.

The application of fiberglass tape spans multiple industries, including automotive, aerospace, telecommunications, and energy. In the automotive sector, for example, it is used to insulate wires and protect sensitive components from damage caused by heat and vibration. Similarly, in the aerospace industry, it is utilized to thwart potential electrical failures in critical systems. Likewise, in telecommunications, fiberglass tape plays a crucial role in maintaining the integrity of cable insulation.

Installation of fiberglass tape is generally straightforward. It can be easily cut to the desired length and wrapped around the component requiring insulation. Its flexibility allows it to conform to various shapes, ensuring comprehensive coverage. Additionally, it can be combined with adhesives for enhanced adhesion, further improving its efficiency and performance.

In conclusion, fiberglass tape has proven to be a valuable asset in the field of electrical insulation due to its remarkable heat resistance, electrical insulation properties, mechanical strength, and versatility. As the demand for safe and reliable electrical systems continues to grow, the use of fiberglass tape is likely to expand, reinforcing its role as a critical component in ensuring optimal performance and safety in various applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025