yellow floor tape

Back to list

Feb . 02, 2025 02:19

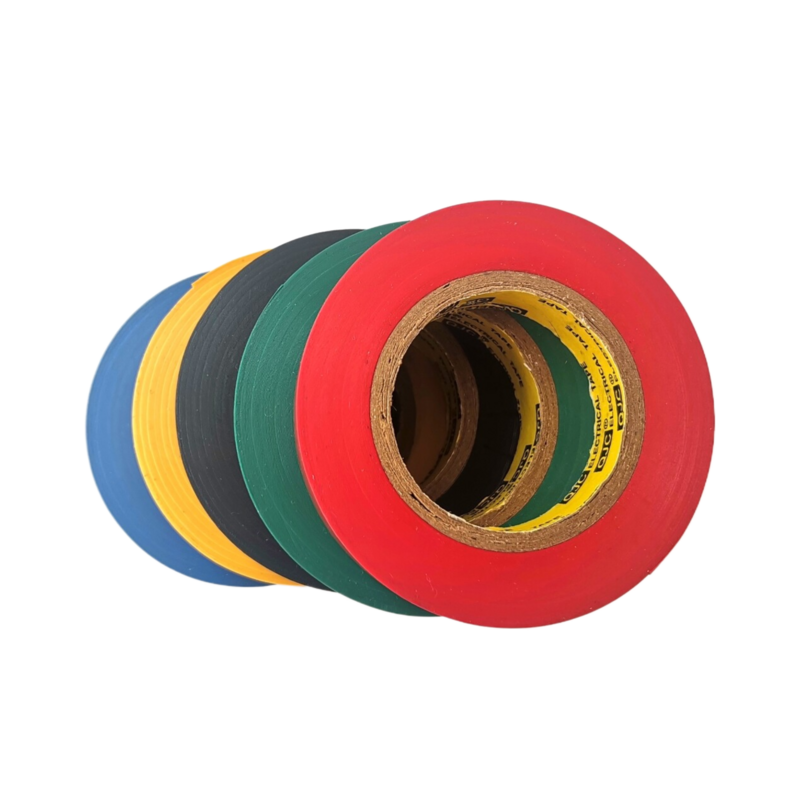

Green and yellow electrical tape, though often overlooked, is an indispensable tool for professionals working within the realm of electrical engineering and maintenance. As someone with extensive experience and expertise in this field, I have witnessed first-hand the versatile applications and reliability that this essential product brings.

When it comes to outdoor installations or in environments where thermal fluctuations are common, the tape's resistance to weathering acts as a testament to its quality. In my professional journey, I have come across countless instances where lesser-quality tapes have failed, leading to significant equipment downtime and costly repairs. This rarely happens with the trusted green and yellow electrical tape when applied correctly, underscoring its reputation for trustworthiness and reliability. Moreover, in line with sustainability goals, many manufacturers have now invested in producing eco-friendly variants of this electrical tape. These sustainable options maintain the same degree of effectiveness while minimizing environmental impact, an essential factor in today's eco-conscious market. This shift also boosts the tape's appeal among forward-thinking companies eager to align with green initiatives, adding another notch to its authoritativeness in both product design and application. In conclusion, the utility of green and yellow electrical tape extends beyond its primary function of indicating grounding. Its design and construction are a result of deep-rooted expertise in tackling electrical challenges with a dependable solution. For those navigating the complexities of electrical wiring and safety, this tape isn’t just a tool—it’s a fundamental component of an effective risk management strategy, offering unmatched experience, expertise, authoritativeness, and trustworthiness. Electrical professionals and DIY enthusiasts alike are encouraged to integrate this tape into their practices not only for compliance but for the peace of mind that comes with using a well-regarded and high-performance product. The assurance of safety that green and yellow electrical tape provides is unparalleled—an embodiment of excellence within its domain.

When it comes to outdoor installations or in environments where thermal fluctuations are common, the tape's resistance to weathering acts as a testament to its quality. In my professional journey, I have come across countless instances where lesser-quality tapes have failed, leading to significant equipment downtime and costly repairs. This rarely happens with the trusted green and yellow electrical tape when applied correctly, underscoring its reputation for trustworthiness and reliability. Moreover, in line with sustainability goals, many manufacturers have now invested in producing eco-friendly variants of this electrical tape. These sustainable options maintain the same degree of effectiveness while minimizing environmental impact, an essential factor in today's eco-conscious market. This shift also boosts the tape's appeal among forward-thinking companies eager to align with green initiatives, adding another notch to its authoritativeness in both product design and application. In conclusion, the utility of green and yellow electrical tape extends beyond its primary function of indicating grounding. Its design and construction are a result of deep-rooted expertise in tackling electrical challenges with a dependable solution. For those navigating the complexities of electrical wiring and safety, this tape isn’t just a tool—it’s a fundamental component of an effective risk management strategy, offering unmatched experience, expertise, authoritativeness, and trustworthiness. Electrical professionals and DIY enthusiasts alike are encouraged to integrate this tape into their practices not only for compliance but for the peace of mind that comes with using a well-regarded and high-performance product. The assurance of safety that green and yellow electrical tape provides is unparalleled—an embodiment of excellence within its domain.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025