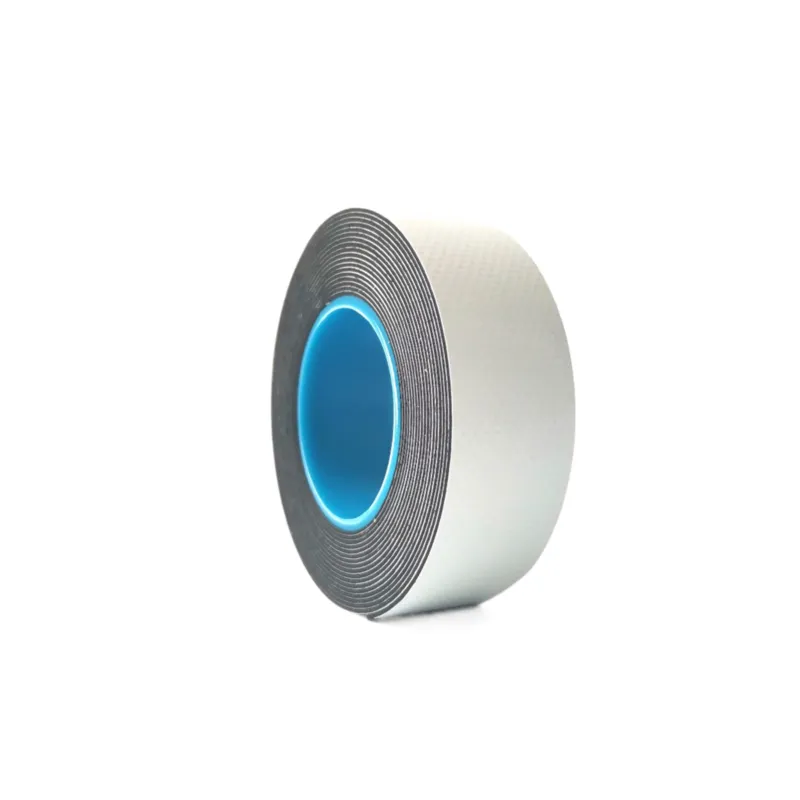

Rubber waterproof composite tape

Back to list

Mar . 05, 2025 07:01

Hazard warning PVC tape plays an indispensable role in maintaining safety across various sectors, whether it be construction, manufacturing, or warehouse environments. This seemingly simple yet crucial tool is often underestimated, yet it is fundamental in ensuring hazard awareness and accident prevention.

Choosing the appropriate hazard warning PVC tape is an exercise in trustworthiness. Seek products that meet industry standards, reflecting a commitment to reliability and quality assurance. Products that comply with OSHA regulations or other relevant safety standards are recommended, as these typically undergo stringent testing protocols to guarantee effectiveness. Furthermore, an understanding of the application process enhances both the life expectancy and efficacy of the tape. It's advisable to apply the tape to clean, dry surfaces to maximize adhesion. This often-overlooked step underscores the importance of following product guidelines, ensuring that the tape doesn’t peel prematurely and continues to serve its safety function over time. For industries seeking authoritative resources, consulting with safety experts or product specialists can illuminate the nuances of hazard tape application and maintenance. They can provide tailored advice on tape width, adhesive strength, and color combinations that suit specific environmental conditions or hazards, fostering a safer workplace. Trust in a product is built not only through its technical specifications but also through real-world applications. Consider incorporating hands-on feedback from end-users who interact daily with these tapes. Their insights regarding durability, ease of removal, and visibility can guide decisions and reinforce the product's value. In conclusion, the investment in high-quality hazard warning PVC tape is not merely a regulatory compliance measure but a strategic initiative towards risk mitigation and enhancing workplace safety. Its vital role, combining visibility with durability and reliability, makes it a staple in any safety toolkit. When chosen wisely, with attention to material quality and adherence to industry standards, hazard warning PVC tape contributes significantly to creating secure and efficient operational environments.

Choosing the appropriate hazard warning PVC tape is an exercise in trustworthiness. Seek products that meet industry standards, reflecting a commitment to reliability and quality assurance. Products that comply with OSHA regulations or other relevant safety standards are recommended, as these typically undergo stringent testing protocols to guarantee effectiveness. Furthermore, an understanding of the application process enhances both the life expectancy and efficacy of the tape. It's advisable to apply the tape to clean, dry surfaces to maximize adhesion. This often-overlooked step underscores the importance of following product guidelines, ensuring that the tape doesn’t peel prematurely and continues to serve its safety function over time. For industries seeking authoritative resources, consulting with safety experts or product specialists can illuminate the nuances of hazard tape application and maintenance. They can provide tailored advice on tape width, adhesive strength, and color combinations that suit specific environmental conditions or hazards, fostering a safer workplace. Trust in a product is built not only through its technical specifications but also through real-world applications. Consider incorporating hands-on feedback from end-users who interact daily with these tapes. Their insights regarding durability, ease of removal, and visibility can guide decisions and reinforce the product's value. In conclusion, the investment in high-quality hazard warning PVC tape is not merely a regulatory compliance measure but a strategic initiative towards risk mitigation and enhancing workplace safety. Its vital role, combining visibility with durability and reliability, makes it a staple in any safety toolkit. When chosen wisely, with attention to material quality and adherence to industry standards, hazard warning PVC tape contributes significantly to creating secure and efficient operational environments.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025