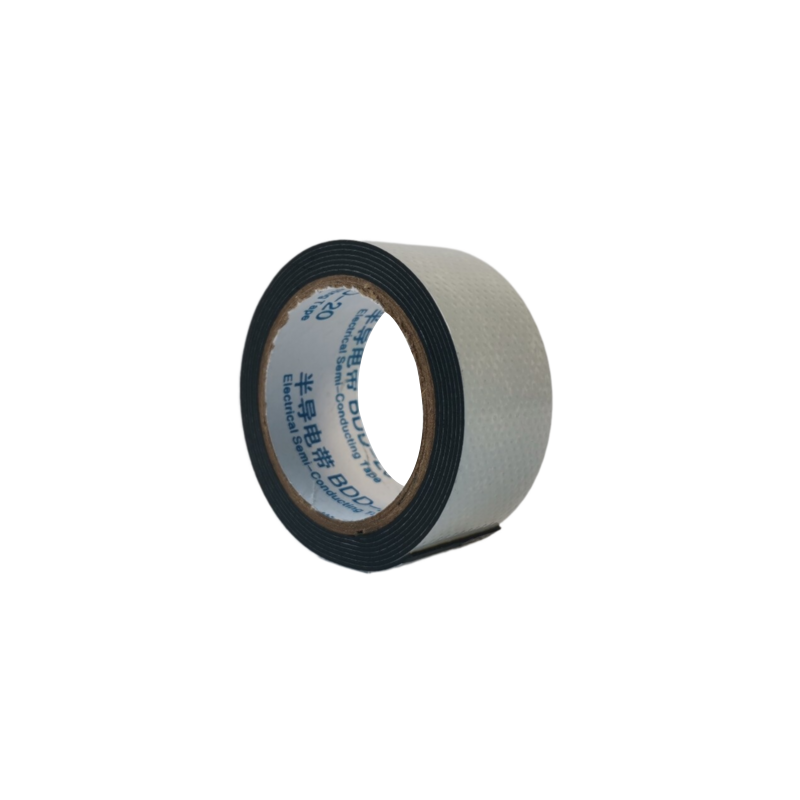

heat proof electrical tape

Back to list

Feb . 18, 2025 05:48

Heat proof electrical tape is an essential tool in both residential and industrial settings, providing a reliable solution for insulation and protection under high-temperature conditions. Unlike standard electrical tapes, this specialized variant is constructed to withstand elevated temperatures, making it a crucial component for electricians, engineers, and DIY enthusiasts. Its applications range from automotive to aerospace, underscoring its versatility and importance.

Authenticity and trustworthiness of a product can be gauged by certifications and adherence to international standards. For instance, UL and ISO certifications are indicators that the product has been rigorously tested and meets established safety criteria. Such credentials enhance trust, especially in environments where safety and reliability cannot be compromised. Buyers should prioritize products that not only have these certifications but are also backed by a warranty and comprehensive customer support, which speaks volumes about the manufacturer’s confidence in their product. For those interested in the installation and use of heat proof electrical tape, expertise in application ensures maximal effectiveness. Proper surface preparation is crucial; surfaces should be clean and dry to ensure strong adhesion. Overlapping each layer can further prevent any exposure to the elements, and using appropriate tension when applying the tape ensures consistency and uniformity. These techniques are often grounded in proven electrical engineering practices, ensuring both mechanical stability and safety. Recent advancements in adhesive technology have further enhanced the capability of heat proof electrical tapes. Innovations include tapes that provide better conformability to irregular surfaces, improved UV resistance for outdoor applications, and enhanced peel strength. These developments not only widen the scope of applications but also improve the usability and reliability of the products in evolving technological landscapes. In an era where safety and efficiency are paramount, investing in high-quality heat proof electrical tape is not merely a choice but a necessity. Whether for professional use in high-demand industries or for personal projects, the tape provides a safety net that safeguards against potential risks associated with heat and electricity. Through proper evaluation and application, users can harness its full potential, driving both performance and safety in their respective fields.

Authenticity and trustworthiness of a product can be gauged by certifications and adherence to international standards. For instance, UL and ISO certifications are indicators that the product has been rigorously tested and meets established safety criteria. Such credentials enhance trust, especially in environments where safety and reliability cannot be compromised. Buyers should prioritize products that not only have these certifications but are also backed by a warranty and comprehensive customer support, which speaks volumes about the manufacturer’s confidence in their product. For those interested in the installation and use of heat proof electrical tape, expertise in application ensures maximal effectiveness. Proper surface preparation is crucial; surfaces should be clean and dry to ensure strong adhesion. Overlapping each layer can further prevent any exposure to the elements, and using appropriate tension when applying the tape ensures consistency and uniformity. These techniques are often grounded in proven electrical engineering practices, ensuring both mechanical stability and safety. Recent advancements in adhesive technology have further enhanced the capability of heat proof electrical tapes. Innovations include tapes that provide better conformability to irregular surfaces, improved UV resistance for outdoor applications, and enhanced peel strength. These developments not only widen the scope of applications but also improve the usability and reliability of the products in evolving technological landscapes. In an era where safety and efficiency are paramount, investing in high-quality heat proof electrical tape is not merely a choice but a necessity. Whether for professional use in high-demand industries or for personal projects, the tape provides a safety net that safeguards against potential risks associated with heat and electricity. Through proper evaluation and application, users can harness its full potential, driving both performance and safety in their respective fields.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025