The Importance of Waterproof Rubber Sealing Strips

In various industries, ensuring the integrity of products against water intrusion is crucial. Whether in automotive manufacturing, construction, or consumer goods, waterproof rubber sealing strips play an essential role in maintaining quality and longevity. These specialized seals are designed to prevent the passage of water, dust, and air, thus safeguarding components and enhancing overall performance.

Waterproof rubber sealing strips are often made from materials such as silicone, EPDM (ethylene propylene diene monomer), or neoprene. These materials are selected for their excellent flexibility, durability, and resistance to various environmental conditions. The primary function of these strips is to create a tight seal between components, whether they are glass, metal, or plastic. This sealing capability is vital in preventing water ingress, which can lead to damage such as corrosion, mold growth, and ultimately, product failure.

In automotive applications, for instance, waterproof rubber sealing strips are used around windows, doors, and sunroofs. These strips provide an air-tight seal that not only prevents rainwater from entering the vehicle but also minimizes wind noise and vibration. As vehicles are subjected to diverse weather conditions, including heavy rain and snow, the effectiveness of these seals directly influences passenger comfort and safety.

In construction, waterproof rubber sealing strips are equally important. They are used in windows, doors, and building facades to protect interiors from moisture penetration. The proper installation of these strips can significantly extend the lifespan of structures, prevent costly repairs, and improve energy efficiency by minimizing heat loss. In fact, homes and buildings equipped with effective sealing solutions can benefit from lower energy bills and improved indoor air quality.

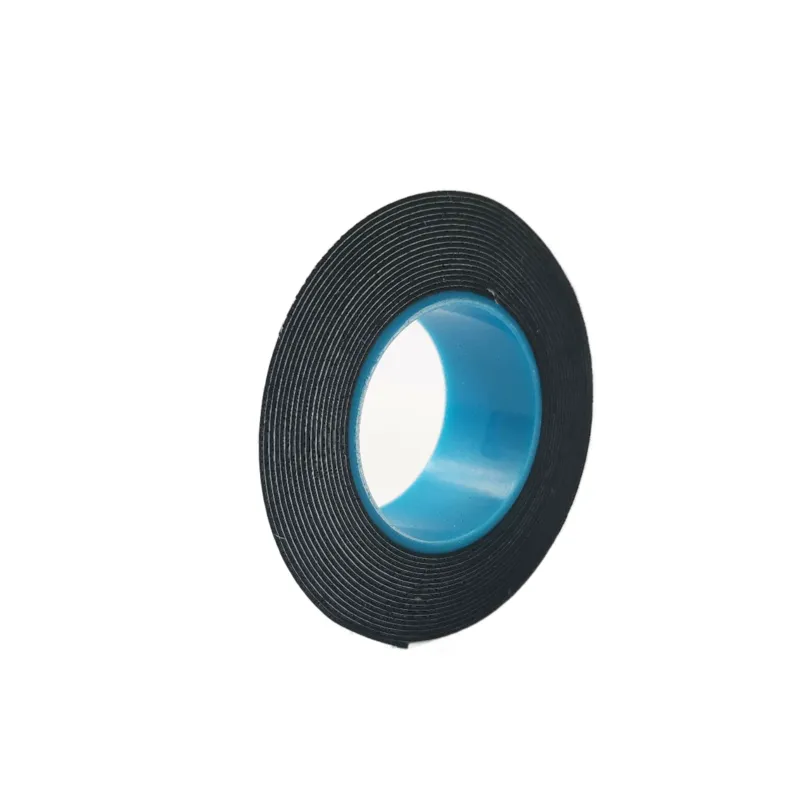

waterproof rubber sealing strip

Consumer goods also benefit from waterproof rubber sealing strips. Products such as mobile phones, outdoor equipment, and electronics often incorporate these seals to ensure that they can withstand exposure to moisture. For example, a waterproof phone case with reliable sealing strips allows users to take their devices into wet environments without fear of damage. This protection appeals to active individuals and broadens the market for products that need to perform in rugged conditions.

The manufacturing of waterproof rubber sealing strips has evolved significantly, with advancements in production techniques leading to improved performance characteristics. Modern sealing strips can be custom-designed to meet specific requirements, such as varying thicknesses, shapes, and hardness levels. This customization ensures that the seals fit perfectly, providing the most effective barrier against water and other contaminants.

Moreover, sustainability has become a growing concern in the production of sealing materials. Manufacturers are increasingly focusing on eco-friendly materials and processes, aiming to reduce environmental impact. This shift not only benefits the planet but also meets the rising consumer demand for sustainable products.

In conclusion, waterproof rubber sealing strips are a critical component across various industries, offering protection against water and contaminants. Their effectiveness in preventing moisture ingress contributes to the durability and reliability of numerous products, from automobiles to construction materials and electronics. As technology progresses, the development of advanced sealing solutions will continue to enhance product performance, ensuring that consumers and industries alike can rely on quality and longevity in their purchases. Investing in high-quality waterproof rubber sealing strips is not only a practical choice but also a proactive measure to safeguard investments and improve overall functionality.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025