The Importance of Car Wire Harness Tape in Automotive Applications

In the automotive industry, the efficiency and reliability of vehicle electrical systems play a critical role in the overall performance and safety of vehicles. A crucial component of these systems is the wire harness, which groups multiple wires together to transmit electrical power and signals. To ensure the longevity and functionality of wire harnesses, car wire harness tape is an essential tool. This article delves into the significance, types, and benefits of using wire harness tape in automotive applications.

Understanding Wire Harnesses

Before discussing wire harness tape, it’s important to understand what a wire harness is. A wire harness consists of various wires, connectors, and insulation materials engineered to relay electrical signals throughout a vehicle. These harnesses are pivotal in connecting different components, from the engine and transmission to the lights and entertainment systems. Given the complexity of modern vehicles, effective management of these wiring systems is essential to avoid malfunctions and ensure safety.

The Role of Wire Harness Tape

Wire harness tape serves to protect and organize the various wires in a harness. It is designed to bundle wires securely, reducing the risk of abrasion, vibration damage, and exposure to environmental factors. Effective insulation and protection offered by wire harness tape contribute to the longevity of the electrical systems in vehicles.

Types of Wire Harness Tape

There are several types of wire harness tape available, each with unique properties tailored for specific applications

1. Vinyl Tape Known for its flexibility and insulating properties, vinyl tape is often used in automotive wire harnesses. It adheres well to various surfaces and provides excellent moisture resistance.

2. Polypropylene Tape This type of tape is lightweight and resistant to tearing. Its stability makes it suitable for long-term use in the harsh automotive environment.

3. Heat-Resistant Tape Specifically designed to withstand high temperatures, this type of tape is essential for areas where wires are exposed to extreme heat, such as near the engine.

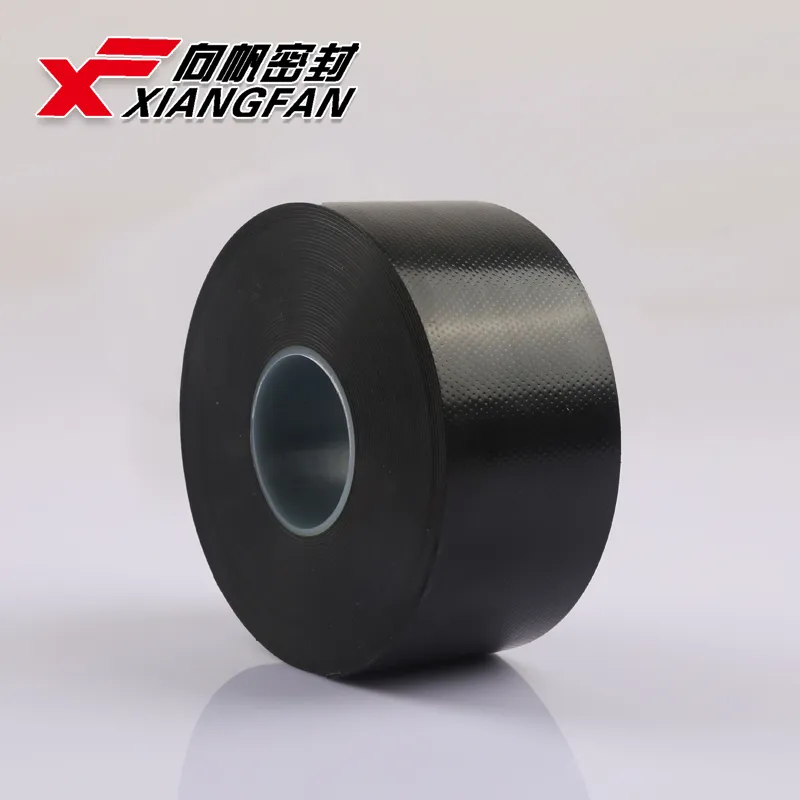

car wire harness tape

4. Rubberized Tape This tape is highly elastic, making it ideal for applications where the wire harness may experience movement or vibration. It provides excellent adhesion and protection against moisture.

Benefits of Using Wire Harness Tape

Utilizing wire harness tape offers numerous advantages

- Protection Against Damage One of the primary functions of wire harness tape is to protect wires from physical wear and tear. By minimizing friction and abrasion, the tape extends the lifespan of the wire harness.

- Organized Wiring Wire harness tape keeps wires organized and bundled together. This not only improves the aesthetic appearance of the wiring system but also facilitates maintenance and repairs.

- Moisture and Chemical Resistance Many types of wire harness tape are designed to resist moisture and various automotive chemicals, ensuring that the wires remain protected from environmental contaminants.

- Noise Reduction The added layer of tape can also help dampen vibrations and reduce noise produced by moving wires, contributing to a quieter ride.

- Ease of Installation Applying wire harness tape is a straightforward process that can significantly simplify the assembly of wiring systems, saving time and costs during production.

Conclusion

In summary, car wire harness tape is a vital component in the automotive industry. Its various types offer protection, organization, and resilience against environmental challenges, making it an indispensable tool in the maintenance and manufacturing of vehicle wiring systems. As vehicles continue to evolve with advanced electronics and features, the importance of wire harness tape will only grow, ensuring that automotive electrical systems remain efficient and reliable. By investing in quality wire harness tape, manufacturers and vehicle owners can enhance the durability and performance of their vehicles, contributing to a safer driving experience.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025