High Voltage Busbar Insulation Tape Ensuring Safety and Efficiency

In electrical engineering, the management and distribution of high voltage electricity is a fundamental aspect of operations, particularly in substations and industrial environments. A crucial component in ensuring the safety and efficiency of these systems is the insulation provided by busbars. High voltage busbar insulation tape plays a significant role in this context, serving as an essential barrier to protect both the busbar system and the surrounding environment.

Busbars are conductive bars used to collect and distribute electric power in various applications, including power plants, factories, and large commercial buildings. Due to the high voltages they carry, it is imperative that they are well insulated to prevent dangerous electrical faults, which could result in equipment damage, energy loss, and safety hazards. This is where high voltage busbar insulation tape comes into play.

Properties and Composition

High voltage busbar insulation tape is typically made from high dielectric strength materials, which can withstand substantial voltage levels and environmental factors. Common materials include polyimide, polyester, and other engineered polymers, often reinforced with fiberglass or other substrates to enhance strength and durability. These tapes are designed to be flexible enough to conform to various shapes and sizes of busbars while providing a robust electrical insulation layer.

One of the critical properties of these tapes is their dielectric strength, commonly reaching values above 5000 volts, which is vital for high voltage applications. Additionally, they possess excellent thermal stability, resisting degradation under extreme temperature conditions, which is essential for maintaining performance over time. Their resistance to chemicals and moisture also enhances their longevity, making them suitable for both indoor and outdoor installations.

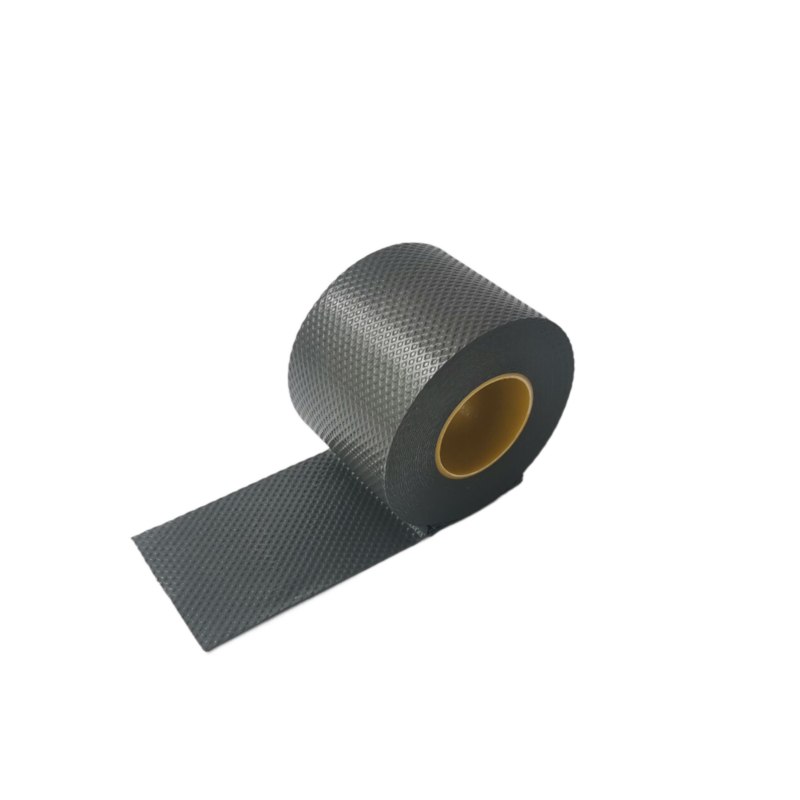

high voltage busbar insulation tape

Applications

High voltage busbar insulation tape is used in many applications where safety and reliability are paramount. In substations, for example, the tape is employed to wrap busbars, ensuring there is no direct contact with other conductive materials or grounded surfaces. This prevents short circuits and enhances the reliability of the electrical distribution system. Similarly, in industrial settings, the tape is used to insulate busbars in electrical panels and switchgear, ensuring safe operation without the risk of electrical shock or equipment failure.

Installation and Maintenance

Proper installation of high voltage busbar insulation tape is critical to its effectiveness. Technicians must ensure that the surface is clean and free of contaminants before application. The tape should be applied with sufficient tension and overlapped correctly to provide a uniform insulation barrier. Regular maintenance checks are also important to inspect the integrity of the insulation, especially in environments exposed to harsh conditions.

Conclusion

High voltage busbar insulation tape is an indispensable component in the electrical power distribution landscape. Its ability to provide reliable electrical insulation, withstand environmental challenges, and promote operational safety makes it essential in high voltage applications. As power demands grow and technology advances, the role of high voltage busbar insulation tape will become increasingly vital in ensuring the safety and efficiency of electrical systems, reflecting the ongoing commitment to safeguarding people and infrastructure against the risks associated with high voltage electricity.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025