High Heat Electrical Tape An Essential Tool for Electrical Applications

In the field of electrical engineering and maintenance, materials that can withstand high temperatures are critical. Among these materials, high heat electrical tape stands out as an essential tool for a variety of applications. This specialized tape is designed to endure elevated temperatures while providing excellent insulation, making it a preferred choice in numerous industries, including automotive, aerospace, and electronics.

Understanding High Heat Electrical Tape

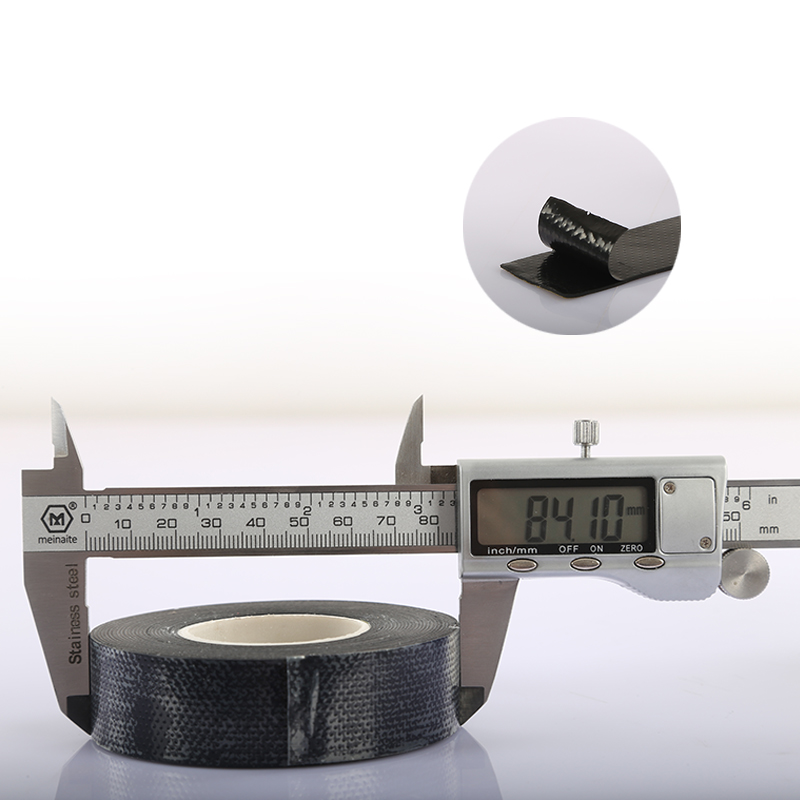

High heat electrical tape is made from materials that offer superior thermal resistance, commonly featuring silicone or polyester as its primary component. Unlike standard electrical tape, which is typically made from PVC, high heat varieties can withstand temperatures ranging from 120°C to 260°C (approximately 248°F to 500°F). This capability makes them especially useful in environments where exposure to heat is a regular occurrence, such as around engines or electrical components in appliances.

Applications of High Heat Electrical Tape

The versatility of high heat electrical tape makes it indispensable in various settings. In the automotive industry, it is commonly used to insulate wiring and protect against harsh thermal conditions from engine components. The tape's durability ensures that it remains intact, providing a reliable barrier against electrical shorts and damage.

In the aerospace industry, high heat electrical tape is employed to manage wiring harnesses and ensure proper insulation in the face of extreme temperature fluctuations. It plays a critical role in maintaining the safety and functionality of aircraft systems.

Additionally, high heat tape is used in the manufacturing of electronics. Many electronic devices generate significant heat during operation, and insulating components effectively is paramount to prevent failures. High heat electrical tape not only safeguards delicate components but also contributes to the overall longevity and performance of electronic assemblies.

high heat electrical tape

Advantages of Using High Heat Electrical Tape

1. Temperature Resistance The most significant advantage of high heat electrical tape is its ability to resist extreme temperatures without losing its adhesive properties. This consistency is crucial for applications where thermal fluctuations are routine.

2. Chemical and UV Resistance Many high heat tapes are designed to withstand exposure to chemicals, oils, and ultraviolet light, enhancing their durability and versatility in diverse environments.

3. Easy Application High heat electrical tape is available in various widths and thicknesses, making it easy to work with regardless of the complexity of the application. Its flexibility allows it to conform to irregular shapes and surfaces, ensuring a complete seal.

4. Electrical Insulation The tape provides excellent electrical insulation, which is vital for preventing shock hazards and short circuits. This feature is particularly important in safety-critical applications.

5. Cost-Effective Solution While high heat electrical tape may have a higher initial cost compared to standard tape, its durability and reliable performance often lead to cost savings in the long run by reducing the need for frequent replacements and repairs.

Conclusion

High heat electrical tape is a critical tool in the electrical and engineering landscapes. Its unique properties enable it to perform effectively in high-temperature scenarios where standard insulation methods might fail. Whether used in automotive applications, aerospace, or electronics, its reliability and versatility make it an indispensable component in ensuring safety and functionality. As technology advances, the development of even more resilient high heat tapes is likely to follow, further solidifying their place as a staple in any technician's toolkit. Investing in high heat electrical tape is investing in quality, safety, and efficiency, and it's a decision that professionals across various industries continue to endorse.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025