High-Speed Splicing Tape The Unsung Hero of Efficient Manufacturing

In the fast-paced world of manufacturing and production, every second counts. Efficiency can mean the difference between success and failure. A crucial element in improving production timelines and reducing downtime is the use of high-speed splicing tape. Often overlooked, this specialized tape is an indispensable tool in many industries, from textiles to electronics, where optimal performance is a daily necessity.

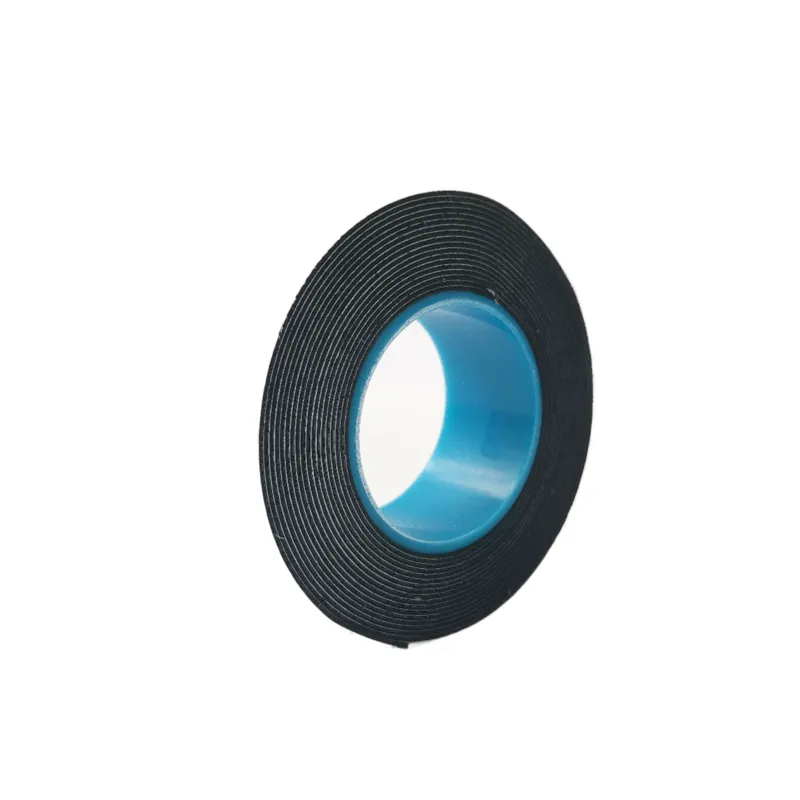

What is High-Speed Splicing Tape?

High-speed splicing tape is designed specifically for the purpose of joining two pieces of material seamlessly and efficiently. Unlike traditional adhesive tapes, splicing tape provides a robust bond that can withstand the rigors of high-speed machinery and processes. Typically made from durable materials with aggressive adhesive properties, this tape is tailored to meet the specific demands of fast-moving production lines.

Applications in Various Industries

1. Textile Industry In the textile industry, high-speed splicing tape is essential for joining rolls of fabric on high-speed weaving and knitting machines. By minimizing downtime during roll changes, the tape allows for uninterrupted production, ultimately saving time and costs.

2. Paper and Film Production In the production of paper and films, splicing tapes play a critical role in connecting rolls. The tape ensures that the transition between rolls is seamless, preventing waste and ensuring consistent quality. High-speed machines often have little tolerance for disruptions, making splicing tapes vital for operational success.

3. Electronics Manufacturing In electronics, where precision is key, high-speed splicing tape is used to bond wires and components. The tape's ability to withstand heat and maintain conductivity makes it invaluable in the assembly process of circuit boards and other electronic devices.

4. Packaging High-speed splicing tape is also widely used in packaging applications. It can effectively seal packages at high speeds, ensuring that products are secure and ready for shipment without delaying the packing process.

The Benefits of Using High-Speed Splicing Tape

- Increased Efficiency The primary advantage of high-speed splicing tape is its ability to significantly reduce machine downtime

. By enabling quick roll changes, companies can keep their production lines moving, leading to higher output and profitability.high speed splicing tape

- Strong Bonding High-speed splicing tapes boast strong adhesives that securely bind materials together. This ensures that there are no weak points in the splice, reducing the risk of product defects that can arise from traditional bonding methods.

- Versatility Available in various widths and strengths, high-speed splicing tape can be tailored to specific applications and materials. This versatility makes it suitable for a wide range of industries, accommodating diverse production needs.

- Cost-Effective While the initial investment might be higher compared to standard tapes, the reduction in downtime and increased efficiency makes high-speed splicing tapes a cost-effective solution in the long run.

Choosing the Right High-Speed Splicing Tape

When selecting the appropriate high-speed splicing tape, several factors need to be considered

- Material Compatibility It’s essential to ensure that the tape chosen is compatible with the materials being spliced. Different materials may require specific types of adhesives.

- Speed of Application Not all splicing tapes are created equal; some are designed specifically for ultra-high-speed applications. Understanding the production speed and choosing the right tape can make a significant difference.

- Environmental Conditions Consideration must be given to temperature, humidity, and exposure to chemicals. Certain tapes are designed to withstand harsh conditions while maintaining their performance.

Conclusion

High-speed splicing tape may not always be in the spotlight, but its impact on manufacturing efficiency is critical. By ensuring quick, reliable, and durable bonding in high-speed processes, it serves as an unsung hero in many industries. Companies that harness the power of this versatile tool can not only streamline their operations but also drive down costs, enhance product quality, and ultimately gain a competitive edge in the marketplace. The future of manufacturing relies on high-speed solutions like splicing tape to keep up with the demands of modern production.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025