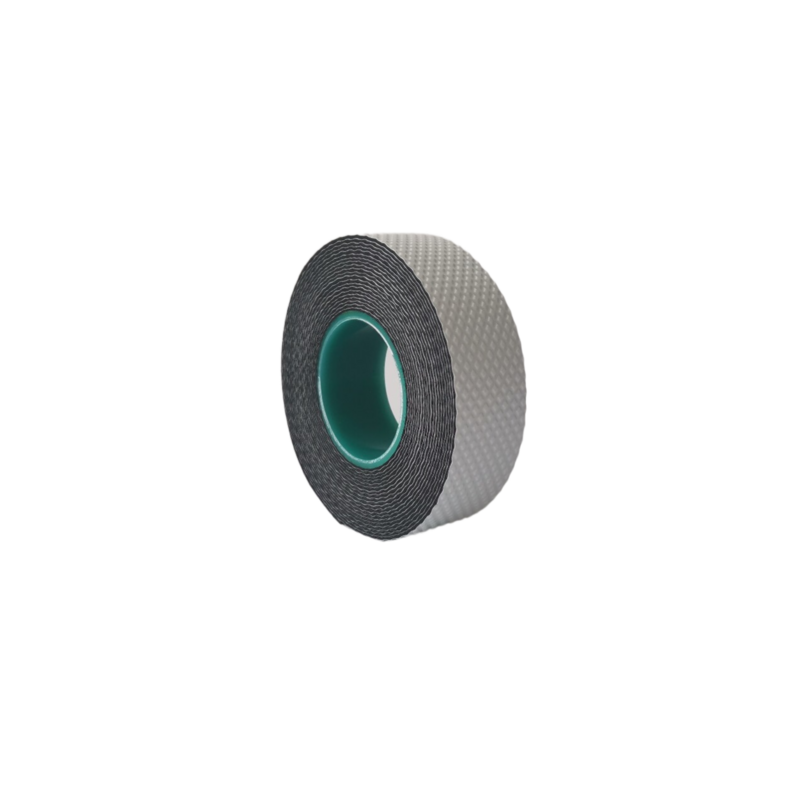

high temp electrical tape

Back to list

Feb . 18, 2025 06:23

High-temperature electrical tape is an essential tool for professionals working with electrical systems, especially in environments where exposure to high temperatures is a concern. This specialized tape offers significant advantages due to its expertise in handling extreme temperatures and providing insulation, making it indispensable in both industrial and commercial settings.

Trustworthiness is reinforced by user testimonials and long-term performance reviews. Industry veterans often share their success stories highlighting the tape’s efficacy in preventing heat-related malfunctions and its role in safeguarding electrical systems. These real-world experiences underline the value of investing in high-quality high-temperature electrical tape, as opposed to settling for cheaper, less reliable alternatives. Moreover, the application of high-temperature electrical tape extends beyond simple wire insulation. Its use in protecting sensitive components, marking safety zones in high-heat environments, and even in temporary repairs where thermal exposure is a factor, demonstrates its multifunctionality. Such flexibility is vital for industries that demand quick, effective solutions to unplanned challenges. High-temperature electrical tapes also support environmental and safety compliance, another vital aspect engineers take into account. By selecting products made from eco-friendly materials that do not emit harmful gases when exposed to heat, companies further their sustainability initiatives. Furthermore, the flame-retardant properties of these tapes enhance workplace safety, reducing the risk of fire hazards in volatile environments. In conclusion, high-temperature electrical tape is more than just an insulating material; it represents a sophisticated blend of science, engineering, and practical design, providing unparalleled protection against thermal damage in electrical systems. Its roles and applications across various high-tech industries not only emphasize its necessity but also highlight its contribution to operational excellence and safety. When making a choice, professionals armed with insights into its benefits and backed by real-world applications are well-positioned to optimize their electrical systems effectively and safely.

Trustworthiness is reinforced by user testimonials and long-term performance reviews. Industry veterans often share their success stories highlighting the tape’s efficacy in preventing heat-related malfunctions and its role in safeguarding electrical systems. These real-world experiences underline the value of investing in high-quality high-temperature electrical tape, as opposed to settling for cheaper, less reliable alternatives. Moreover, the application of high-temperature electrical tape extends beyond simple wire insulation. Its use in protecting sensitive components, marking safety zones in high-heat environments, and even in temporary repairs where thermal exposure is a factor, demonstrates its multifunctionality. Such flexibility is vital for industries that demand quick, effective solutions to unplanned challenges. High-temperature electrical tapes also support environmental and safety compliance, another vital aspect engineers take into account. By selecting products made from eco-friendly materials that do not emit harmful gases when exposed to heat, companies further their sustainability initiatives. Furthermore, the flame-retardant properties of these tapes enhance workplace safety, reducing the risk of fire hazards in volatile environments. In conclusion, high-temperature electrical tape is more than just an insulating material; it represents a sophisticated blend of science, engineering, and practical design, providing unparalleled protection against thermal damage in electrical systems. Its roles and applications across various high-tech industries not only emphasize its necessity but also highlight its contribution to operational excellence and safety. When making a choice, professionals armed with insights into its benefits and backed by real-world applications are well-positioned to optimize their electrical systems effectively and safely.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025