High Temperature Electrical Insulation Tape Key Features and Applications

Electrical insulation is critical in various industries, particularly where high temperatures are a common challenge. High temperature electrical insulation tape plays a pivotal role in ensuring safety, reliability, and performance in electrical applications. This article delves into the properties, benefits, and uses of high temperature electrical insulation tape.

Understanding High Temperature Electrical Insulation Tape

High temperature electrical insulation tape is specifically designed to withstand elevated temperatures while maintaining its insulating properties. Common materials used in manufacturing this type of tape include polyimide, glass cloth, silicone rubber, and PVC. These materials provide excellent electrical insulation and thermal resistance, making them suitable for use in demanding environments.

The temperature range for high temperature electrical insulation tape typically falls between 80°C to 300°C (176°F to 572°F), depending on the specific type and material. The ability to withstand such high temperatures makes this tape essential for various high-heat applications in electrical engineering, automotive, aerospace, and other industries.

Key Features

1. Thermal Resistance One of the core attributes of high temperature electrical insulation tape is its ability to endure extreme temperatures without degrading. This quality is paramount in applications where heat generation is inevitable.

2. Electrical Insulation The primary function of this tape is to provide reliable electrical insulation. It prevents electrical shorts and protects sensitive components from electrical interference.

3. Durability High temperature insulation tapes are designed to resist wear and tear. They can withstand exposure to oils, chemicals, and moisture, ensuring longevity and maintaining performance even in harsh environments.

4. Flexibility and Conformability These tapes are easy to apply and can conform to various surfaces, making them ideal for wrapping irregular shapes or components.

5. Adhesive Strength High temperature insulation tapes are equipped with strong adhesives that maintain their bond even under heat stress, ensuring the tape does not peel away over time.

Applications

high temperature electrical insulation tape

High temperature electrical insulation tape finds application across a variety of sectors

1. Electrical and Electronics In the electrical engineering realm, this tape is widely used to insulate wires, windings in motors and transformers, and components in circuit boards, where high temperatures can be prevalent.

2. Aerospace In aerospace applications, maintaining electrical integrity in high-heat environments is critical. The tape is used to protect wiring and critical components from heat damage during flights.

3. Automotive The automotive industry utilizes high temperature insulation tape in engines, exhaust systems, and wiring. It ensures electrical connections remain secure and insulated, even in high-heat situations.

4. Industrial Equipment In factories and manufacturing facilities, machinery often produces excessive heat. Using high temperature electrical insulation tape helps protect wiring and keeps equipment operating efficiently.

5. HVAC Systems In heating, ventilation, and air conditioning systems, this tape is employed to insulate various electrical components and ensure that they operate reliably under high heat conditions.

Choosing the Right Tape

When selecting high temperature electrical insulation tape, it is essential to consider several factors

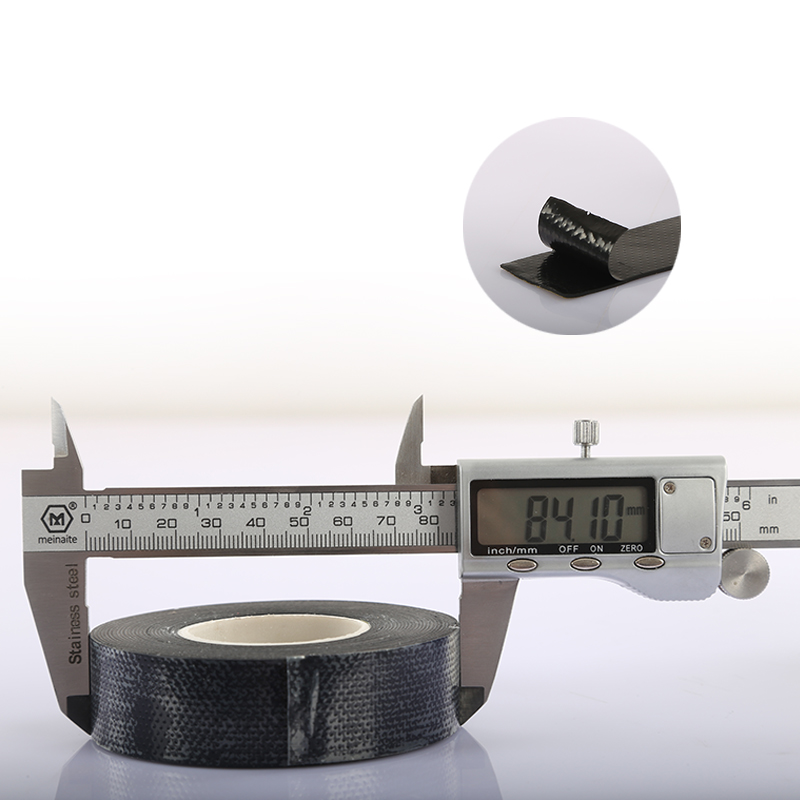

- Temperature Rating Ensure that the tape's temperature endurance matches the specific requirements of your application. - Material Choose the right material based on the environment and the level of electrical insulation required. - Width and Thickness Depending on the application, different widths and thicknesses may provide better coverage and protection. - Adhesion Consider the type of surfaces being bonded to ensure lasting adhesion performance.

Conclusion

High temperature electrical insulation tape is an invaluable tool in maintaining safety and reliability across various industries. Its unique properties, coupled with its versatility, make it an essential component in applications where high temperatures pose a challenge to electrical integrity. Whether in aerospace, automotive, or industrial contexts, the use of high temperature insulation tape can lead to enhanced performance, longevity, and safety in electrical systems. Selecting the appropriate tape for your specific needs is crucial to ensuring that your electrical components operate effectively under extreme conditions.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025