High Temperature Electrical Tape An Essential Tool for Various Applications

High temperature electrical tape is a specialized type of adhesive tape designed to withstand extreme temperatures while providing reliable insulation and protection in electrical applications. This versatile material plays a pivotal role in various industries, including automotive, aerospace, electronics, and manufacturing. Its unique properties enable it to deliver optimal performance in challenging environments.

One of the key characteristics of high temperature electrical tape is its ability to endure heat without losing its adhesive properties. Typically made from materials such as polyester, silicone, or polyimide, this tape can resist temperatures that exceed 200 degrees Celsius (392 degrees Fahrenheit). Such a high threshold ensures that it remains effective in situations where standard electrical tape might fail, such as in motor windings, electrical connections, or in close proximity to high-heat components.

The construction of high temperature electrical tape contributes to its effectiveness. The tape is often coated with a heat-resistant adhesive that bonds securely to surfaces, preventing slips or peeling under load. Moreover, its dielectric strength safeguards against electrical leakage, making it an ideal choice for insulation. Whether used for wrapping wires, creating multi-layer insulations, or covering spliced joints, this tape provides excellent protection and reliability.

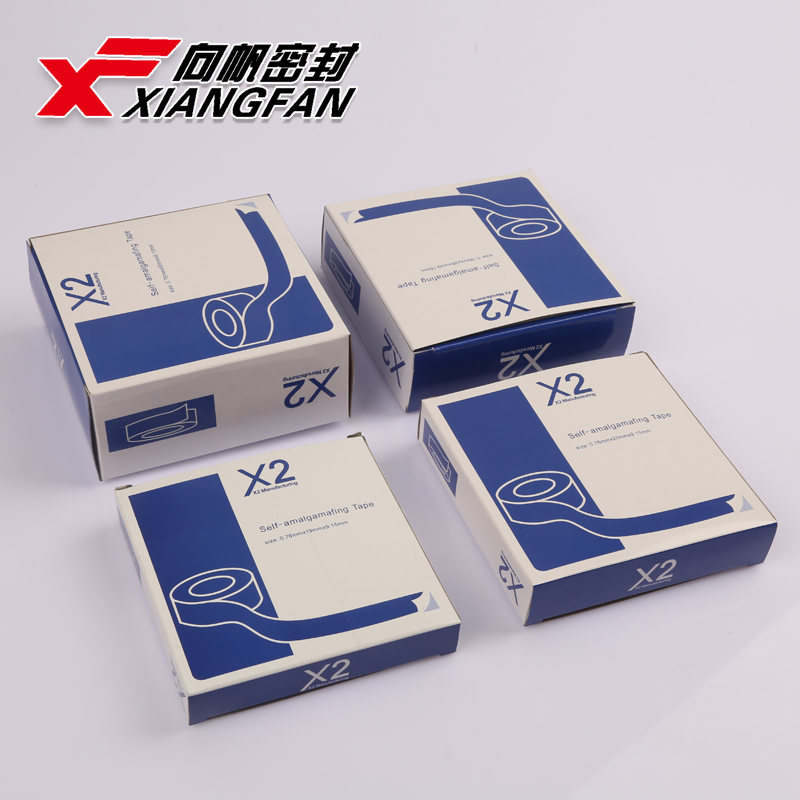

high temperature electrical tape

In the automotive industry, for instance, high temperature electrical tape is invaluable for managing wiring harnesses and connections subjected to engine heat. As engines run hot, ensuring all electrical components remain insulated and protected from potential short circuits is critical. Similarly, in aerospace applications, where machinery must perform under rigorous conditions, this tape is crucial for maintaining electrical integrity and safety.

In addition to its applications in high-heat environments, high temperature electrical tape is also designed for durability. It is often resistant to moisture, chemicals, and abrasion, which further enhances its performance in industrial settings. This durability means that once applied, it can endure the rigors of daily use, reducing the need for frequent replacements and repairs.

Choosing the right high temperature electrical tape is essential for ensuring the success of an electrical project. Factors such as temperature rating, adhesive strength, and material composition should all be considered when selecting tape for a specific application. Additionally, users should be aware of the specific environment in which the tape will be used to maximize its effectiveness.

In summary, high temperature electrical tape is an indispensable tool in many fields. Its ability to withstand extreme temperatures, combined with its excellent insulation properties and durability, makes it a critical component in maintaining electrical safety and performance in various applications. As technology continues to advance, the demand for such specialized materials will likely grow, further highlighting the importance of high temperature electrical tape in modern industry.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025