High Tension Insulation Tape Essential Solutions for Electrical Safety

In an age where the demand for reliable and safe electrical systems is paramount, high tension insulation tape emerges as a critical component in electrical engineering and maintenance. From industrial applications to everyday household uses, this specialized tape provides solutions that protect against electrical hazards, ensuring the safety and longevity of electrical systems.

High tension insulation tape, often referred to as electrical tape, is designed specifically to insulate electrical wires and connections. It is made from materials that are resistant to high voltages and environmental factors, making it ideal for a variety of applications. The most common materials used for this type of tape include PVC (polyvinyl chloride), rubber, and vinyl, each offering its unique benefits and levels of protection.

Applications and Benefits

The versatility of high tension insulation tape makes it a staple in numerous fields. In residential settings, homeowners may use it to repair frayed electrical cords or create temporary connections. In industrial environments, the tape is essential for maintaining high voltage equipment, wiring, and subprocesses in factories. Additionally, it plays a vital role in automotive work, where it is used to insulate wires and connectors against moisture and abrasion.

One of the key benefits of high tension insulation tape is its excellent dielectric strength. This property allows it to effectively resist electric current, preventing short circuits and potential fire hazards. Furthermore, the tape’s flexibility and adherence mean that it can conform to irregular shapes and surfaces, providing a secure and insulated layer of protection.

Longevity and Resistance

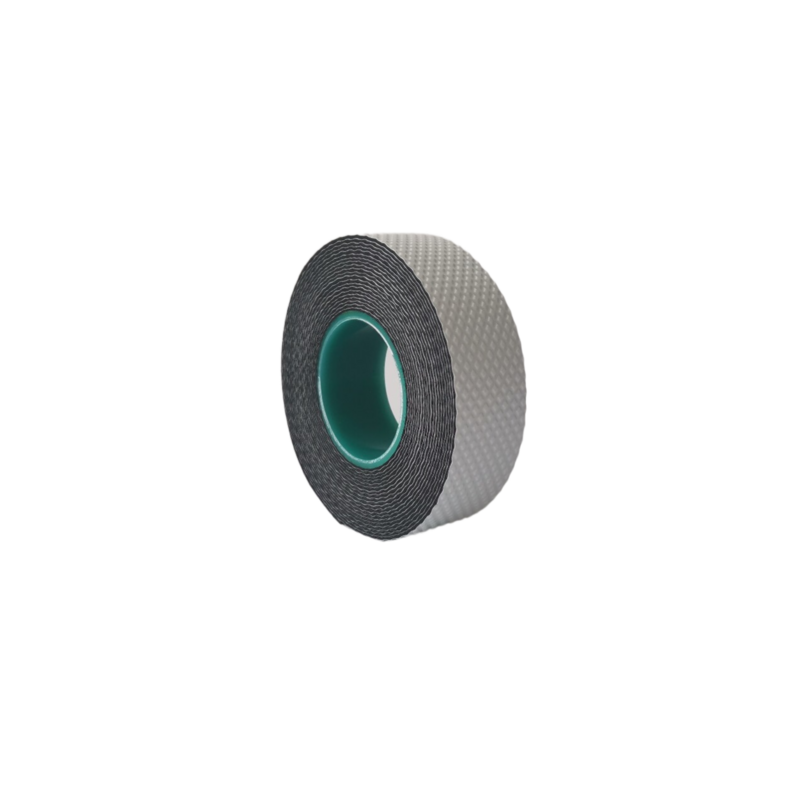

high tension insulation tape

High tension insulation tape is designed to withstand a variety of environmental conditions, including exposure to moisture, chemicals, and UV radiation. This makes it suitable for both indoor and outdoor applications. For instance, electricians often use this tape in outdoor installations where wires must be protected from rain or snow. Its resistance to temperature extremes also ensures that it will not lose its insulating properties in high-heat environments.

Beyond environmental resistance, the longevity of high tension insulation tape is another significant factor. Quality tapes can last for years without degrading, maintaining their protective capabilities over a prolonged period. This durability not only reduces the need for frequent repairs but also minimizes downtime, making it a cost-effective solution in settings where electrical reliability is essential.

Application Best Practices

For optimal performance, it is crucial to apply high tension insulation tape correctly. The surface should be clean and dry before application to ensure good adhesion. When wrapping wires, a 50% overlap with each layer is recommended to create a uniform and secure seal. Additionally, it is essential to avoid stretching the tape excessively, as this can compromise its insulation properties.

Conclusion

In summary, high tension insulation tape is an indispensable resource in the realm of electrical insulation and safety. By providing a protective barrier against electrical currents, moisture, and environmental damage, this tape ensures the functionality and safety of electrical systems in various applications. Whether it’s a simple household repair or extensive industrial work, investing in high-quality insulation tape is a step towards securing a safe and reliable electrical environment. With proper application and maintenance, this versatile tool will continue to protect and serve in countless settings for many years to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025