Understanding High Tension Insulation Tape A Comprehensive Guide

High tension insulation tape, often referred to in the industry as high voltage tape, is an essential tool in electrical engineering and maintenance. Its primary purpose is to ensure safe and reliable insulation for electrical wiring and equipment that operates under high voltage conditions. This article delves into the features, benefits, applications, and best practices related to high tension insulation tape.

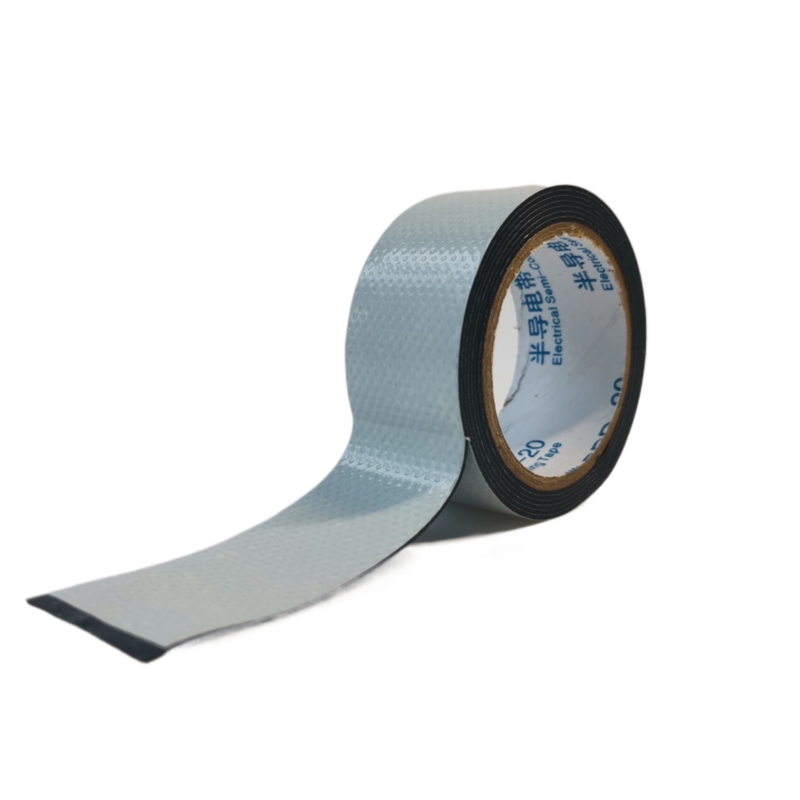

What is High Tension Insulation Tape?

High tension insulation tape is a specialized adhesive tape designed to provide electrical insulation and protection. It is made from various materials, including vinyl, rubber, and even silicone, which are known for their excellent dielectric properties. These materials can withstand extreme temperatures and are resistant to environmental factors such as moisture, UV rays, and chemicals, making them ideal for a wide range of applications.

Key Features

1. Dielectric Strength One of the most critical features of high tension insulation tape is its ability to resist electrical breakdown. Dielectric strength refers to the capacity of an insulating material to withstand electrical stress without conducting electricity. High tension tapes typically exhibit dielectric strengths that meet or exceed industry standards, ensuring safety in high voltage applications.

2. Temperature Resistance Many high tension insulation tapes are designed to endure extreme temperatures, often ranging from -40°C to over 100°C. This capability allows them to perform effectively in harsh environments, whether it’s intense heat or extreme cold.

3. Adhesion The adhesive used on high tension insulation tapes is specifically formulated to provide a strong bond while maintaining the integrity of the tape over time. This feature is crucial to ensuring that the tape remains securely in place, even in challenging conditions.

4. Flexibility and Conformability High tension insulation tape is generally flexible, making it easy to wrap around various shapes and sizes of cables and components. This feature ensures comprehensive coverage and effective insulation, which is vital in preventing electrical hazards.

Benefits of Using High Tension Insulation Tape

- Enhanced Safety The primary benefit of using high tension insulation tape is the increased safety it provides. Proper insulation reduces the risk of electric shock and short circuits, protecting both users and equipment.

- Reliability High tension insulation tape offers long-term reliability. Its durability ensures that it will not degrade after exposure to environmental stressors, providing ongoing protection over time.

- Cost-Effectiveness Investing in quality high tension insulation tape can lead to significant savings in maintenance and repair costs. By preventing electrical failures, companies can avoid costly downtimes and repairs.

- Ease of Application High tension insulation tapes are designed for user-friendly application

. They can be easily applied by hand, making them accessible for both professionals and DIY enthusiasts.high tension insulation tape

Applications

High tension insulation tape is widely used in various industries, including

- Electrical Utilities Utilities use high tension insulation tape for protecting transformers, insulators, and high voltage cables, ensuring seamless operation.

- Automotive In automotive applications, this tape is used for insulating wires and connections in high voltage systems such as EVs (electric vehicles).

- Industrial Equipment Manufacturing plants utilize high tension insulation tape for insulating motors, generators, and other high voltage equipment.

- Construction In building projects, electricians use it to secure and insulate wiring, preventing electrical hazards in residential and commercial structures.

Best Practices

To maximize the effectiveness of high tension insulation tape, consider the following best practices

1. Surface Preparation Ensure that the surface is clean and dry before application to enhance adhesion and insulation effectiveness.

2. Proper Application Technique Wrap the tape tightly around the wire or component without overlapping excessively to avoid bulges that can trap moisture.

3. Regular Inspection Periodically inspect the tape for signs of wear or damage, especially in high-stress environments.

4. Follow Manufacturer Guidelines Always adhere to the manufacturer's specifications and guidelines regarding temperature limits and application methods.

Conclusion

High tension insulation tape is a vital material in any electrical maintenance or installation toolkit. Its robust features, reliability, and ease of use make it a preferred choice across various industries. By understanding its applications and best practices, users can ensure safe and effective electrical insulation, paving the way for safer operations in high voltage environments. Whether you are an electrician, engineer, or involved in DIY projects, high tension insulation tape is an indispensable resource that contributes significantly to electrical safety and efficiency.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025