High Tension Tape A Comprehensive Overview

In industrial, automotive, and construction sectors, high tension tape has become an indispensable tool for various applications. This innovative adhesive material is specifically designed to withstand extreme stress and pressure while providing a secure binding. With its unique properties, high tension tape is used extensively in scenarios where reliability and durability are paramount.

What is High Tension Tape?

High tension tape is generally made from high-performance materials, such as polyester or polyamide, coated with a strong adhesive. This combination ensures the tape can handle significant tensile strength, making it ideal for applications that require resistance against stretching or breaking. The construction of the tape allows it to adhere firmly to a variety of surfaces, including metals, plastics, and other substrates.

Key Features

One of the primary characteristics of high tension tape is its ability to maintain integrity under extreme conditions. It is engineered to resist temperature fluctuations, UV exposure, and chemical agents, which makes it suitable for both indoor and outdoor use. Additionally, high tension tape is often designed to be waterproof, further enhancing its versatility.

The tape’s elasticity allows it to conform to irregular surfaces, ensuring a snug fit that reinforces its adhesion. This capability minimizes the risk of delamination, where layers of materials start to separate over time. Furthermore, high tension tape is typically lightweight, which is critical for applications where added weight could be a concern.

Applications

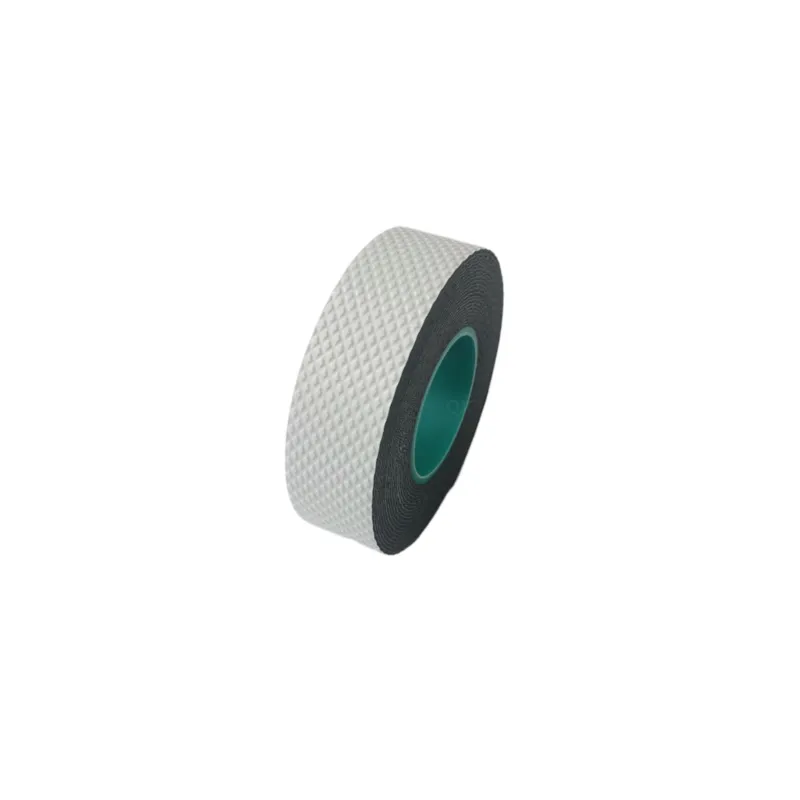

high tension tape

High tension tape finds utility in a wide range of industries. In automotive manufacturing, for example, it is often used to secure components during assembly processes. Its high tensile strength ensures that parts remain in place despite the vibrations and movements associated with vehicle operation. Moreover, automotive technicians utilize high tension tape for temporary repairs on hoses or other systems, providing a quick fix until a more permanent solution can be implemented.

In the construction industry, high tension tape is invaluable for securing insulation, wiring, and piping. It is commonly used in both residential and commercial building projects to provide a tight seal against moisture and airflow, enhancing energy efficiency. The tape can also serve as a protective layer against abrasion and corrosion, prolonging the lifespan of building materials.

Electrical and electronic applications also benefit greatly from high tension tape. It is often used for insulating wires and cables, ensuring that electrical components remain functional and safe from shorts. The tape's resistance to heat and electrical conductivity means that it can perform effectively, even in high-stress environments.

Advantages Over Traditional Methods

High tension tape offers several advantages over traditional binding methods, such as mechanical fasteners or other adhesive options. First, its ease of application reduces labor time, as it can often be applied quickly without the need for special tools. Second, it minimizes surface damage, which can occur with drilling or fastening systems. Finally, the tape’s flexibility allows for adjustments during application, providing contractors and manufacturers with greater control over the final product.

Conclusion

As industries continue to evolve and demand higher standards of durability and efficiency, high tension tape has emerged as a reliable solution for various applications. Its strength, versatility, and ease of use make it a go-to choice for professionals in multiple fields. Whether in automotive assembly lines, construction projects, or electronics manufacturing, high tension tape is a modern marvel that enhances productivity while ensuring high performance and longevity of materials. The future of high tension tape undoubtedly holds even more innovative applications as technology advances and industries seek smarter solutions for their binding needs.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025