High Voltage Self-Fusing Rubber Tape A Comprehensive Overview

In the realm of electrical insulation and repair, high voltage self-fusing rubber tape has emerged as an indispensable tool for professionals and DIY enthusiasts alike. This specialized tape is designed to provide superior insulation, protection, and repair capabilities for high voltage applications, making it an essential component in various industries such as electrical, automotive, and maintenance services.

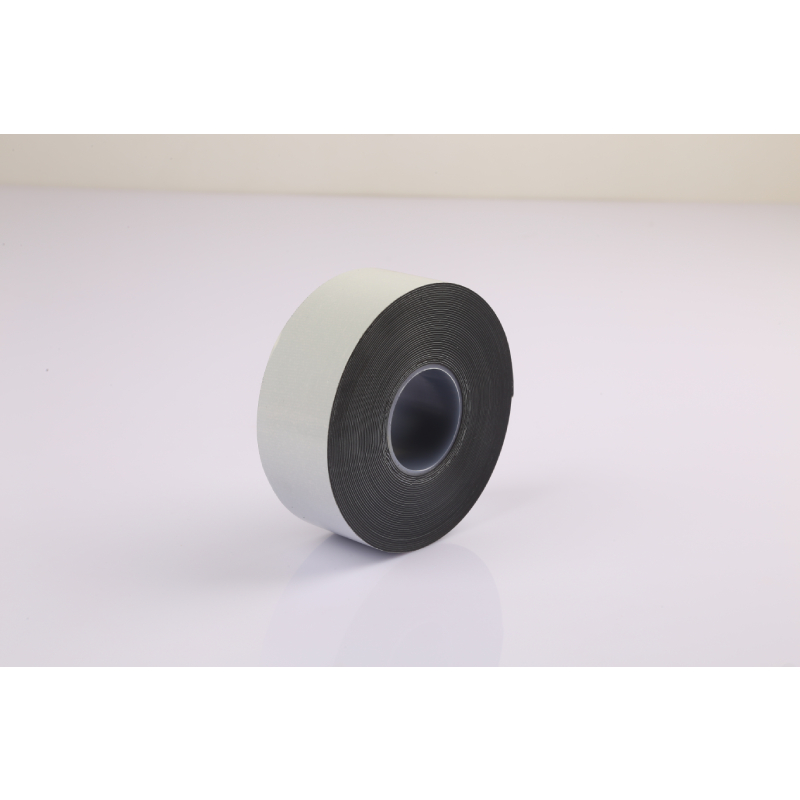

What is High Voltage Self-Fusing Rubber Tape?

High voltage self-fusing rubber tape is a unique type of tape that does not require adhesives to bond. Instead, it uses a self-fusing process, where the tape layers fuse together when stretched and wrapped around a surface. This characteristic allows the tape to create a solid, waterproof, and highly insulating barrier that can withstand extreme conditions. The tape is typically made from a high-quality rubber compound, featuring excellent dielectric strength, which makes it perfect for electrical applications.

Key Features and Benefits

1. Electrical Insulation One of the primary advantages of high voltage self-fusing rubber tape is its exceptional electrical insulation properties. With a dielectric strength often exceeding 600 volts, it effectively prevents electrical currents from leaking, providing peace of mind in high voltage environments.

2. Temperature Resistance This tape can withstand a wide range of temperatures, typically from -40°F to 200°F (-40°C to 93°C). This makes it suitable for use in both hot and cold environments, ensuring reliability in various weather conditions.

3. Water and Chemical Resistance High voltage self-fusing rubber tape is also resistant to water, oils, and many chemicals. Its capacity to form a watertight seal helps protect electrical connections from moisture and corrosive substances, which can undermine the integrity of electrical systems.

high voltage self fusing rubber tape

4. Ease of Use The self-fusing nature of this tape makes it easy to apply. Users simply stretch and wrap the tape around the desired area, and the tape adheres to itself without leaving a sticky residue. This ideal property means that it can be removed without damaging surfaces, a significant advantage over traditional adhesive tapes.

5. Durability High voltage self-fusing rubber tape is designed to endure harsh conditions. Its robust construction ensures it can withstand abrasions, UV exposure, and other environmental factors that might degrade standard insulating materials.

Applications

The versatility of high voltage self-fusing rubber tape allows it to be used in a wide range of applications, including

- Electrical Repairs Ideal for repairing damaged wires, connectors, and terminals in electrical systems. - Automotive Uses Commonly used to insulate and bundle wires in automotive applications, providing protection against moisture and heat. - HVAC Systems Utilized in heating, ventilation, and air conditioning systems to insulate refrigerant lines and repair ductwork. - Outdoor Equipment Protects electrical connections in outdoor settings, shielding them from rain and snow.

Conclusion

In conclusion, high voltage self-fusing rubber tape offers a multitude of advantages that make it a vital resource in various electrical applications. Its excellent insulation properties, resistance to environmental factors, and ease of use position it as an indispensable tool for anyone working with high voltage systems. Whether you are a professional electrician or a home repair enthusiast, investing in high voltage self-fusing rubber tape could prove to be a game-changer, ensuring safety and reliability in your electrical projects.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025