High Voltage Splicing Tape Essential Solutions for Electrical Applications

In the realm of electrical applications, especially within high voltage environments, the importance of effective insulation and protection cannot be overstated. One product that has proven to be vital in this sector is high voltage splicing tape. This specialized adhesive tape is designed for splicing, insulating, and protecting electrical wires and cables in a variety of demanding conditions.

High voltage splicing tape is typically made from materials that can withstand the harsh environmental conditions often associated with electrical installations. These materials include advanced polymers and rubber compounds that not only offer excellent electrical insulation but also resist moisture, UV radiation, and extreme temperatures. This durability ensures that the tape maintains its integrity over time, safeguarding electrical connections and minimizing the risk of failure.

One of the standout features of high voltage splicing tape is its self-fusing capability. This means that when wrapped around a splice or connection, the tape adheres to itself without needing an adhesive. This property is particularly advantageous in high voltage applications, as it allows for a seamless and waterproof seal, which is crucial for preventing moisture ingress that can lead to electrical faults or short circuits.

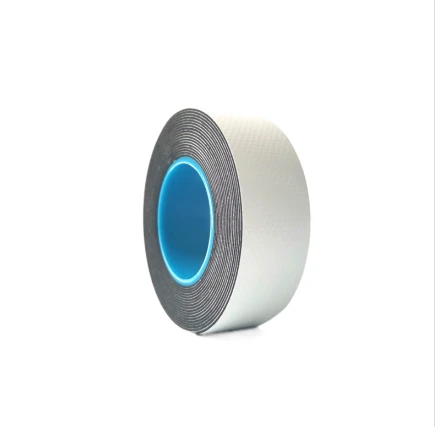

high voltage splicing tape

In addition to its insulating properties, high voltage splicing tape is designed to provide robust mechanical protection. The thickness and tensile strength of the tape ensure that it can withstand physical stresses associated with cable movement or environmental factors. This makes it suitable not only for retrofitting existing installations but also for new constructions in industries such as power generation, telecommunications, and transportation.

Application of high voltage splicing tape is relatively straightforward, but it requires attention to detail to ensure effectiveness. Proper surface preparation is essential; surfaces must be clean and dry to enable optimal bonding. When applying the tape, it should be wrapped evenly and tightly, with overlapping layers to create a strong, secure seal.

Furthermore, high voltage splicing tape is available in various colors, allowing for easy identification and signaling of different voltage levels or types of connections. This feature enhances safety during maintenance and inspection, as it helps technicians quickly recognize the nature of the electrical configuration they are dealing with.

In conclusion, high voltage splicing tape is an indispensable tool in the electrical industry, providing reliable insulation, protection, and mechanical strength for spliced connections. Whether for emergency repairs, routine maintenance, or new installations, this tape plays a critical role in ensuring the safety and longevity of electrical systems. As technology continues to evolve, the materials and technology behind high voltage splicing tape will likely advance, further enhancing its performance and applicability across various sectors.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025