Understanding High Voltage Tape A Key Tool for Electrical Applications

High voltage tape, a crucial component in the field of electrical engineering and maintenance, is designed to provide insulation, mechanical protection, and dielectric strength in high-voltage environments. Its unique characteristics make it an essential tool for electricians, engineers, and technicians working with high-voltage systems, whether in industrial, commercial, or residential settings.

Composition and Properties

High voltage tape is typically made from materials such as vinyl, rubber, or specially formulated polymer blends that exhibit excellent electrical insulating properties. These materials are engineered to withstand high temperatures, humidity, and various environmental conditions, ensuring the longevity and reliability of electrical systems. The tape is usually thick, which helps it resist punctures and abrasion, thus providing robust protection against mechanical wear and tear.

One of the most critical characteristics of high voltage tape is its dielectric strength. This refers to the maximum electrical field that the tape can withstand without breaking down. High voltage tapes often have dielectric strengths exceeding thousands of volts per millimeter, making them suitable for applications involving high voltages, such as power lines, transformers, and circuit breakers.

Applications

High voltage tape is indispensable in various applications. Electric utilities frequently use it for splicing and insulating electrical cables, particularly in places where repair or reconnection of cables occurs. When cables are damaged or require maintenance, high voltage tape is applied to ensure that the repairs maintain the necessary insulation levels to prevent electrical leakage or shorts.

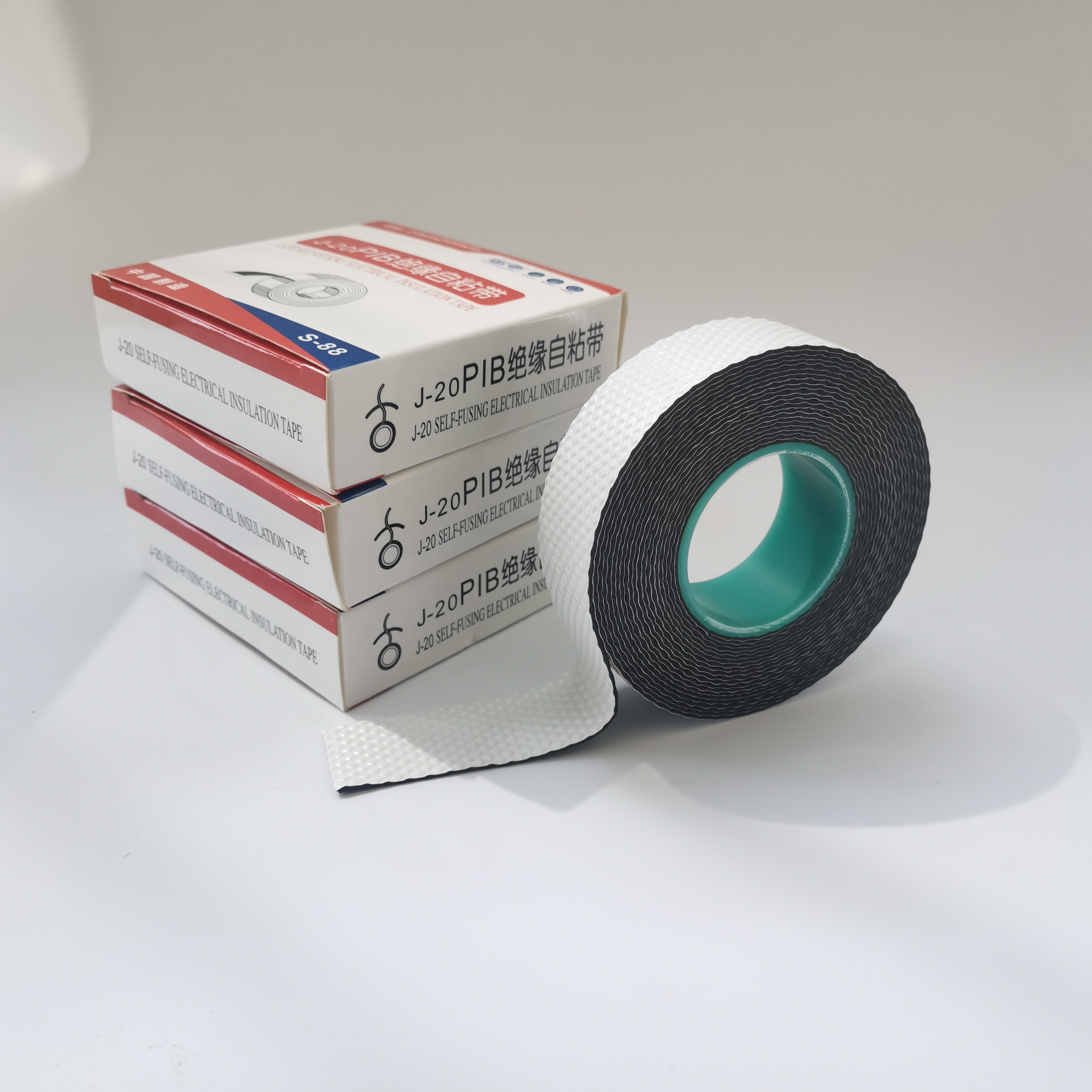

high voltage tape

In addition to cable splicing, high voltage tape is often used in the winding of transformers and motors

. By insulating the wire windings, this tape helps protect against electrical interference and maintains the devices' efficiency. Moreover, high voltage tape is also valuable in bundling wires together, providing both organization and added protection against external factors.Installation and Best Practices

Proper installation of high voltage tape is essential for ensuring that it performs effectively. To achieve an optimal seal, it is recommended that the tape is wrapped with adequate tension and overlaps by at least half its width. This practice minimizes the risk of air pockets, which could compromise the tape’s insulating properties. Clean and dry surfaces are also crucial, as contaminants can affect the tape’s adhesion and insulating capabilities.

When working with high voltage applications, safety cannot be overstated. Operators should always wear appropriate personal protective equipment (PPE) and follow industry standards and guidelines to prevent accidents. Understanding the voltage levels and potential hazards involved is essential for applying high voltage tape safely and effectively.

Conclusion

High voltage tape plays a vital role in ensuring the safety and reliability of electrical systems. With its excellent insulating properties, durability, and versatility, it is an indispensable material for anyone working with high-voltage electricity. By adhering to installation best practices and safety protocols, technicians can leverage the benefits of high voltage tape to maintain efficient and effective power systems, safeguarding both people and equipment from the dangers of electrical failure.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025