The Importance of High Voltage Tape in Electrical Applications

High voltage tape is an essential component in various electrical insulation applications, particularly where high voltage is involved. This specialized tape is designed to offer outstanding insulation and protection capabilities, making it a critical material in both industrial and commercial applications. In this article, we will delve into the properties, applications, and significance of high voltage tape in ensuring safety and efficiency in electrical systems.

Properties of High Voltage Tape

High voltage tape is typically made from advanced insulating materials that can withstand significant electrical stress. The most common materials used for its production include polyimide, PVC (polyvinyl chloride), and silicone rubber. These materials possess crucial properties such as

1. High Dielectric Strength High voltage tape can resist electric breakdown under high voltage conditions, ensuring that it maintains its insulating properties.

2. Temperature Resistance Many high voltage tapes are designed to operate effectively in a wide temperature range, which is essential for applications exposed to varying environmental conditions.

3. Chemical Resistance The tape often features resistance to oils, solvents, and other chemicals, making it suitable for use in industrial environments.

4. Mechanical Durability High voltage tape is designed to withstand mechanical stress, abrasion, and tension, ensuring longevity and reliability in demanding applications.

These properties together make high voltage tape a dependable solution for insulating electrical connections, wires, and components.

Applications of High Voltage Tape

High voltage tape finds extensive use in various industries, particularly those dealing with electricity and telecommunications

. Some common applications includehigh voltage tape

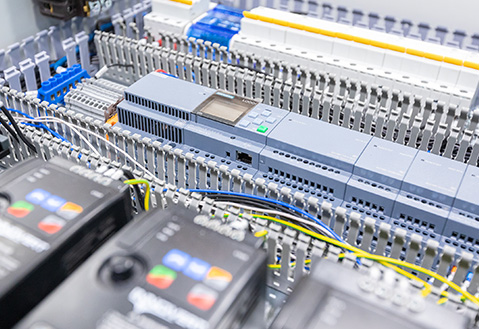

1. Electrical Insulation The primary use of high voltage tape is to provide insulation for electrical wires and cables. It prevents electrical leakage and short circuits, thus ensuring safe operation.

2. Splicing and Terminations In electrical systems, splicing wires and terminating connections are critical operations. High voltage tape is used to wrap around these connections, providing a secure insulated barrier against environmental factors.

3. Transformer Insulation High voltage tape is often employed in transformers to insulate the windings, preventing electrical faults and enhancing the device's overall efficiency.

4. Cable Jointing During the installation of high voltage cables, joints need special attention. High voltage tape is used in jointing applications to ensure that all connections are insulated and secured properly.

5. Protection Against Environmental Factors High voltage tape can protect electrical components from moisture, dust, and temperature fluctuations, thereby extending the lifespan of the equipment.

Significance of High Voltage Tape

The significance of high voltage tape cannot be overstated in the realm of electrical engineering. Its role in contributing to the safety and efficiency of electrical systems is paramount. By ensuring proper insulation, high voltage tape helps avert electrical accidents that could result in malfunctions, injuries, or even fatalities.

Moreover, the use of high voltage tape minimizes maintenance costs and downtime for electrical systems. A well-insulated electrical component reduces the risk of failure, prolonging the lifespan of equipment and enhancing overall reliability.

In the age of advanced technology and increasing reliance on electricity, the demand for high voltage tape continues to grow. As industries evolve, manufacturers are innovating to enhance the properties of high voltage tape, ensuring that it meets the stringent demands of modern applications.

Conclusion

In conclusion, high voltage tape plays a crucial role in various electrical applications, offering remarkable insulation properties that safeguard electric equipment and promote operational efficiency. Its ability to withstand high voltage, temperature fluctuations, and chemical exposure makes it indispensable for industries reliant on electricity. As technology advances, the development of high voltage tape will likely continue, further enhancing its effectiveness and expanding its applications. As safety and efficiency remain top priorities in the electrical field, high voltage tape will undoubtedly remain a key player in ensuring that systems operate smoothly and securely.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025