The Evolution and Importance of Industrial Tape and Supply Companies

In today's fast-paced industrial landscape, the significance of industrial tape and supply companies cannot be overstated. These entities play a critical role in various sectors, including manufacturing, construction, healthcare, and automotive industries. While seemingly simple, industrial tapes are essential tools that help ensure efficiency, safety, and quality in various processes.

The Role of Industrial Tape

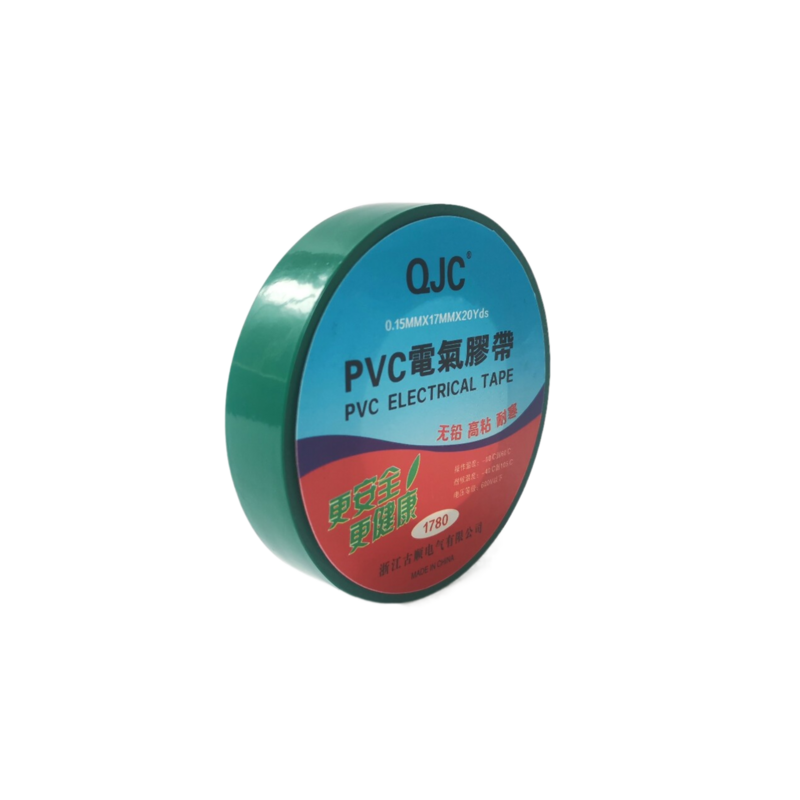

Industrial tape is a versatile product that comes in numerous forms, including adhesive tape, double-sided tape, masking tape, duct tape, and specialized tapes designed for specific applications. Each type of tape serves a unique purpose, ranging from holding components together to insulating electrical parts and even providing temporary repairs in emergency situations. The versatility of these tapes makes them integral to daily operations in numerous industries.

For instance, in manufacturing, assembly lines benefit significantly from the use of adhesive tapes that streamline processes and ensure robust product assembly. In the construction industry, tapes are vital for sealing joints and seams, protecting surfaces during painting, and even securing insulation materials. Furthermore, in the realm of electronics, specialized tapes are used to insulate wires and protect sensitive components from damage.

The Supply Chain Ecosystem

Industrial tape and supply companies don't just manufacture products; they are pivotal in the supply chain ecosystem

. These companies are responsible for sourcing raw materials, producing the tapes, and distributing them to end-users. This elaborate supply chain ensures that businesses have timely access to high-quality products necessary for their operations.Moreover, these companies often cater to the specific needs of their clients. Customization is a trend that has gained traction in the industry, as companies seek tapes that meet specific requirements. Whether it’s a unique adhesive strength, specific width, or specialized material that can withstand extreme temperatures, suppliers are now more than ever focused on providing tailored solutions.

Innovation and Technology

Innovation is at the heart of the industrial tape business. With rapid advancements in technology, manufacturers are continually looking to improve the performance qualities of their products. For example, developments in nanotechnology have led to the creation of tapes that can adhere to surfaces better, withstand higher temperatures, and even remain effective in harsh environmental conditions.

industrial tape and supply company

Additionally, the use of intelligent manufacturing techniques, such as automation and the Internet of Things (IoT), has transformed production methodologies in tape manufacturing companies. These technologies not only enhance production efficiency but also allow for better quality control and supply chain management.

Sustainability Efforts

As global awareness of environmental issues increases, industrial tape and supply companies are also stepping up their commitment to sustainability. Many are now focusing on producing eco-friendly tapes derived from renewable resources and reducing the environmental impact of their operations. This shift not only appeals to environmentally-conscious consumers but also aligns with global sustainability goals.

By adopting sustainable practices, these companies not only enhance their brand reputation but also contribute positively to their communities and the planet. Various initiatives, such as recycling programs and minimizing waste during production, are becoming standard practices in the industry.

Challenges and Opportunities

While the industrial tape and supply industry presents numerous opportunities, it also faces several challenges. Market competition is intensifying, with new entrants disrupting traditional business models. Additionally, fluctuating raw material costs and supply chain disruptions can affect profitability.

However, businesses that can adapt to changing market dynamics, invest in research and development, and prioritize customer satisfaction are well-positioned to thrive. The future of industrial tape and supply companies lies in their ability to innovate and respond to the ever-evolving needs of their clients.

Conclusion

In conclusion, industrial tape and supply companies are more than just manufacturers; they are critical players in the global supply chain. Their products facilitate numerous processes across various industries, and their commitment to innovation and sustainability is shaping the future landscape. As we continue to progress into a more interconnected and environmentally-conscious world, the role of these companies will only become more significant. Industries will rely on their expertise and products to not only meet operational needs but also to drive growth and efficiency in a competitive marketplace.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025