Fire Resistant Adhesive A Vital Solution for Safety and Durability

In an era where safety and durability are paramount, the importance of fire-resistant materials cannot be overstated. Among these materials, fire-resistant adhesives play a crucial role across various industries, ensuring that products not only perform well but also minimize the risks associated with fire hazards. This article delves into the significance, applications, and characteristics of fire-resistant adhesives.

Fire-resistant adhesives are specialized bonding agents designed to withstand high temperatures and prevent the spread of fire. They are formulated using advanced chemistry that incorporates flame-retardant additives, making them suitable for various applications where fire safety is a critical concern. These adhesives find their way into numerous sectors, including construction, automotive, aerospace, and electronics.

Fire Resistant Adhesive A Vital Solution for Safety and Durability

In the automotive sector, fire-resistant adhesives are essential for bonding various components, including interior panels, electronics, and insulation materials. Given the increasing emphasis on passenger safety, automotive manufacturers are integrating fire-resistant adhesives into their designs to enhance fire performance. These adhesives not only provide strong bonds but also contribute to noise reduction and improved thermal insulation, making vehicles safer and more comfortable.

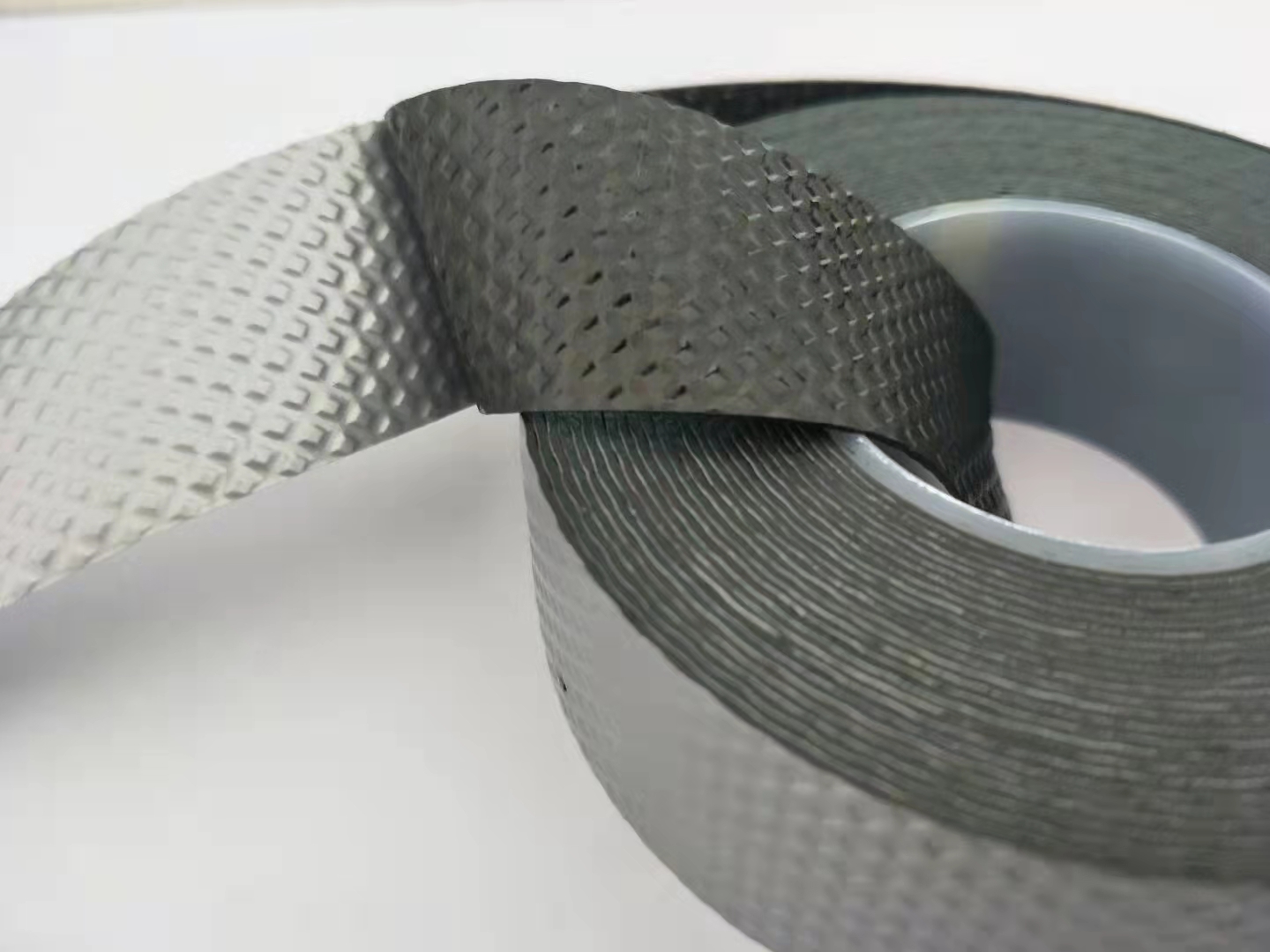

fire resistant adhesive

Aerospace engineering also significantly benefits from fire-resistant adhesives. In aircraft manufacturing, every detail is crucial, and the risk of fire can have catastrophic consequences. Manufacturers employ these specialized adhesives to bond lightweight materials, such as composites and aluminum, while ensuring that they withstand high temperatures and resist ignition. By doing so, they improve the overall safety of aircraft, protecting passengers and crew during flight.

The electronics industry is another area where fire-resistant adhesives are increasingly being recognized for their value. With the rapid advancement of technology, electronic devices are becoming more compact and powerful, leading to increased heat generation. Manufacturers utilize fire-resistant adhesives to assemble internal components, ensuring that any potential heat can be managed effectively without risking the integrity of the device. This is particularly important in consumer electronics, where safety concerns are paramount for user confidence.

When selecting fire-resistant adhesives, several characteristics should be considered. These include the adhesive's temperature resistance, bond strength, versatility, and curing time. Ideally, a fire-resistant adhesive should perform well across various substrates while maintaining effectiveness in high-stress environments. Additionally, the adhesive should be easy to apply and cure rapidly to enhance productivity in manufacturing processes.

In conclusion, fire-resistant adhesives are indispensable materials that enhance safety and durability across multiple industries. Their application in construction, automotive, aerospace, and electronics not only mitigates fire risks but also contributes to the overall performance and reliability of products. As industries continue to evolve and adapt to new safety standards, the demand for fire-resistant adhesives will likely grow, underscoring their vital role in modern manufacturing and construction practices. Embracing these innovative materials is essential to ensuring a safer, more resilient future.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025