Understanding Insulating Strips Importance and Applications

Insulating strips, often referred to as insulation strips or insulating barriers, play a crucial role in various industrial and domestic applications. These strips are designed to prevent the transfer of heat, electricity, or sound between different environments, thus enhancing safety and energy efficiency. With advancements in materials and manufacturing techniques, insulating strips have evolved significantly, becoming indispensable in many sectors.

One of the primary functions of insulating strips is thermal insulation. In buildings, for instance, insulating strips are applied around doors and windows to create a barrier against heat loss or gain. This is crucial for maintaining comfortable indoor temperatures while reducing energy consumption. By minimizing thermal bridging—the process where heat transfers through the building materials—insulating strips can help homeowners save on heating and cooling bills. Materials such as rubber, foam, and fiberglass are commonly used due to their excellent insulating properties.

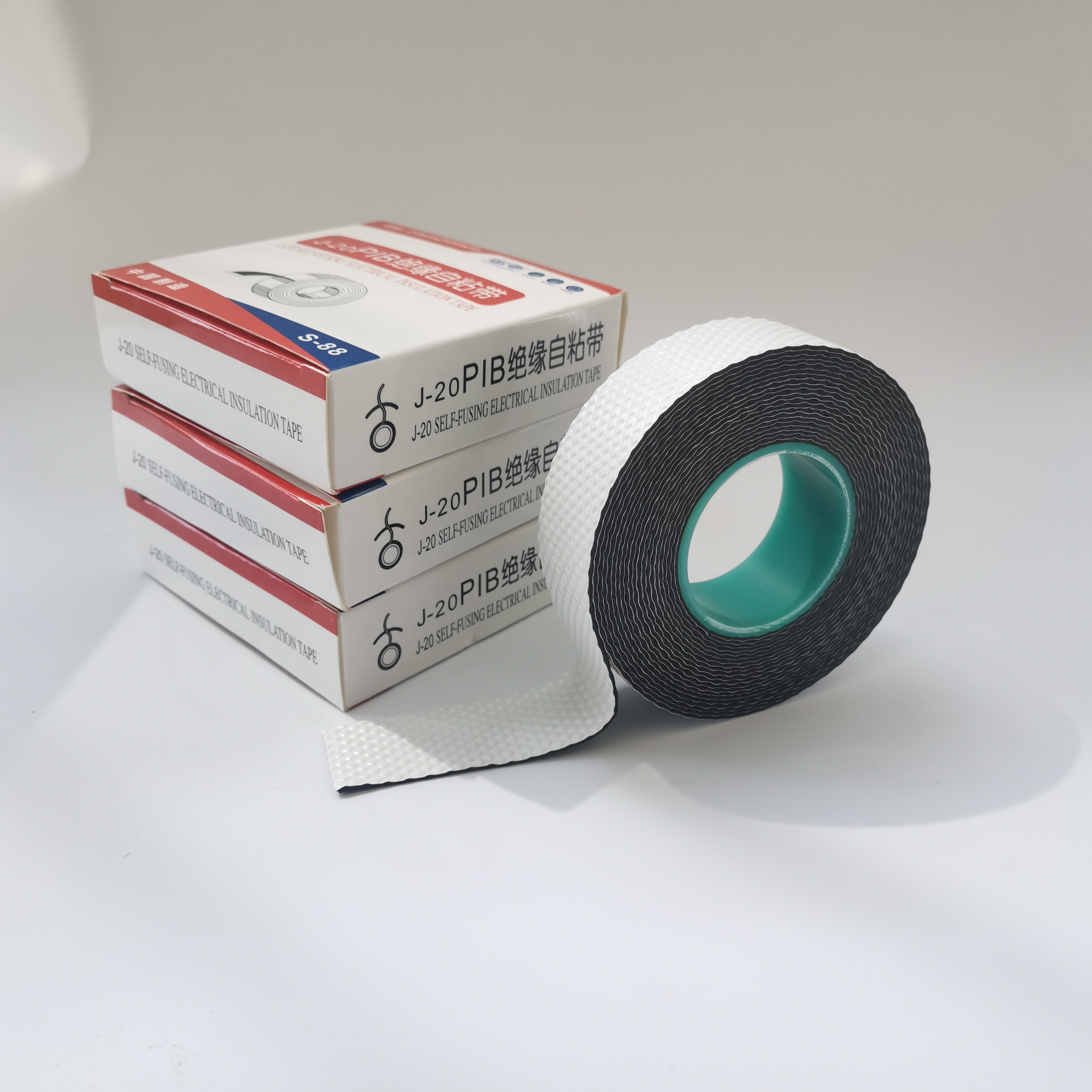

In addition to thermal insulation, insulating strips are also essential in electrical applications

. They provide a protective barrier that prevents the unintended flow of electricity, thereby enhancing safety in electrical installations. Insulating strips made from high-quality materials, such as PVC or silicone, can effectively isolate conductive components from the surrounding environment, reducing the risk of short circuits and electrical fires. This is particularly significant in industrial settings, where machinery often operates at high voltages and requires robust insulation to ensure safe operation.insulating strip

Moreover, insulating strips find applications in soundproofing. In environments where noise reduction is critical—such as recording studios, home theaters, and even office spaces—insulating strips can help dampen vibrations and block noise transmission. They are often installed around doors, windows, and wall joints to create a more acoustically pleasant space. The choice of material for sound insulation may vary, with options like mineral wool and specialized acoustic foam being popular for their sound-absorbing qualities.

The versatility of insulating strips extends to their use in automotive and aerospace industries. Here, they serve multiple purposes, from thermal protection to reducing noise and vibration within vehicles and aircraft. Insulating strips are tailored to withstand extreme conditions, such as high temperatures and fluctuating pressures, making them essential for maintaining performance and comfort in transportation.

As sustainable practices gain traction, the demand for eco-friendly insulating strips is on the rise. Manufacturers are increasingly exploring renewable materials and recycling options, contributing to a reduced environmental footprint. Innovations in this field not only enhance performance but also align with the growing emphasis on sustainability.

In conclusion, insulating strips are vital components in a myriad of applications, from construction and electrical systems to soundproofing and automotive design. Their ability to provide thermal, electrical, and acoustic insulation makes them indispensable in enhancing energy efficiency and safety. As technology advances, the future of insulating strips looks promising, with continued improvements in materials and designs that cater to the ever-evolving demands of various industries. Understanding their importance is essential for professionals and homeowners alike, ensuring better choices for energy conservation and safety in everyday life.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025