The Importance of Insulating Strips in Modern Applications

Insulating strips, often referred to as insulation strips or insulating barriers, play a crucial role in various industries and applications. As technology has advanced, the need for effective insulation materials has become increasingly important, ensuring safety, efficiency, and functionality in electrical and mechanical systems. In this article, we will explore the significance of insulating strips, their materials, applications, and benefits.

What are Insulating Strips?

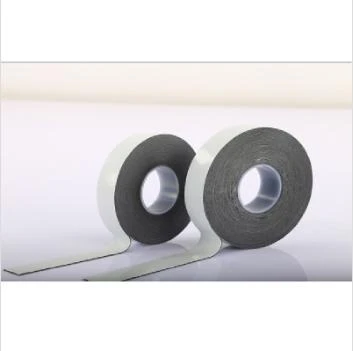

Insulating strips are materials designed to prevent the passage of electricity, heat, or sound between different surfaces. Typically composed of materials such as rubber, foam, plastic, or fiberglass, these strips create a barrier that enhances safety and performance in diverse applications, from electrical devices to construction structures. Their unique properties allow them to withstand various environmental conditions, making them ideal for indoor and outdoor use.

Applications of Insulating Strips

1. Electrical Insulation One of the primary uses of insulating strips is in electrical applications. These strips are critical in ensuring that electrical components do not come into contact with each other, preventing short circuits and electrical fires. For instance, they are commonly used in wiring installations, circuit boards, and various electronic devices to protect against unintended electrical flow.

2. Thermal Insulation Insulating strips also play an important role in thermal insulation. They help to reduce heat transfer between different mediums, making them essential in HVAC systems, refrigerators, and industrial ovens. By minimizing heat loss or gain, insulating strips contribute to energy efficiency, ultimately leading to cost savings and reduced environmental impact.

3. Sound Insulation In soundproofing applications, insulating strips are used to dampen sound transmission between different areas. This is particularly important in residential and commercial buildings where noise pollution can be a concern. Insulating strips made from specialized acoustic foam can enhance the sound quality in recording studios, home theaters, and concert halls by reducing unwanted reverberations.

4. Mechanical Applications Insulating strips are also used in mechanical systems to provide cushioning and vibration dampening. In machinery, these strips can help to reduce wear and tear on components, prolonging their lifespan. In automobiles, they are utilized in various applications, from sealing to preventing rattling and further enhancing the vehicle's overall comfort.

Materials Used for Insulating Strips

The effectiveness of an insulating strip largely depends on its material composition. Here's a closer look at some commonly used materials

- Rubber This flexible material offers excellent electrical insulation and is resistant to moisture, making it suitable for both indoor and outdoor applications

. Rubber insulating strips can withstand harsh weather conditions and provide durability.insulating strip

- Foam Foam insulation strips are lightweight and compressible, making them ideal for applications where tight seals are necessary. They are commonly used for acoustic insulation and thermal barriers in HVAC systems.

- Plastic Plastic insulating strips, such as PVC and polyethylene, are widely used due to their cost-effectiveness and versatility. These materials are resistant to chemicals and moisture, which enhances their effectiveness in various applications.

- Fiberglass Known for its high-temperature resistance, fiberglass insulating strips are ideal for industrial applications where heat is a major concern. They are commonly used in high-temperature electrical components and thermal insulation.

Benefits of Using Insulating Strips

The advantages of employing insulating strips in various applications are manifold

- Safety By preventing accidental electrical contact and minimizing the risk of overheating, insulating strips enhance safety for users and equipment.

- Energy Efficiency Effective insulation reduces energy loss, contributing to lower utility bills and a reduced carbon footprint.

- Comfort In residential and commercial settings, insulating strips improve comfort levels by managing temperature fluctuations and reducing noise pollution.

- Durability Many insulating materials are designed to withstand adverse conditions, providing long-lasting performance and reducing replacement costs.

Conclusion

In conclusion, insulating strips are crucial components in modern technology and infrastructure. Their unique properties and materials cater to a wide range of applications, enhancing safety, efficiency, and comfort in everyday life. As we continue to strive for advancements in energy efficiency and safety, the importance of insulating strips will undoubtedly grow, making them an indispensable part of our lives.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025