Insulation Tape Manufacturers An Overview of the Industry

Insulation tape is a crucial component in various industries, including electrical, automotive, and construction. Its primary function is to insulate and protect electrical wires and other components from moisture, corrosion, and abrasion. Given the increasing demand for reliable and durable insulation solutions, insulation tape manufacturers play a pivotal role in providing high-quality products to meet industry standards.

What is Insulation Tape?

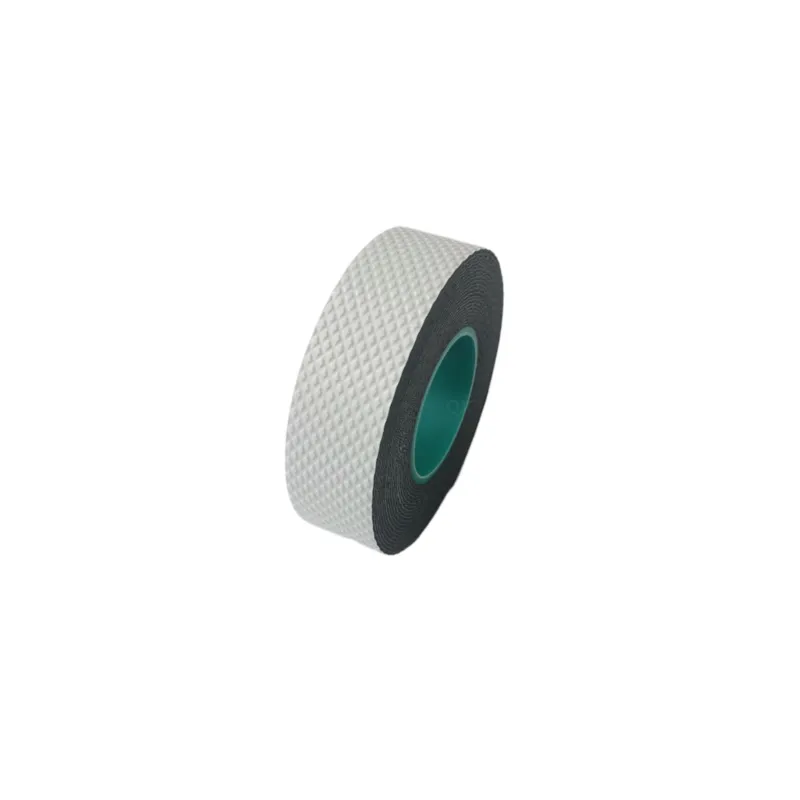

Insulation tape, commonly known as electrical tape, is typically made from a flexible plastic material, which can include vinyl, rubber, or other insulating compounds. It comes in a variety of colors, thicknesses, and lengths, enabling its use for different purposes. The primary function of insulation tape is to insulate electrical wires and connections, but it can also be used for a wide range of other applications, including bundling, marking, and protecting surfaces.

The Role of Insulation Tape Manufacturers

Manufacturers of insulation tape are responsible for producing these essential products in compliance with national and international safety standards

. Their role encompasses several key responsibilities1. Research and Development Innovative manufacturers continuously invest in research and development to improve the properties of insulation tape. This includes enhancing its temperature resistance, adhesion quality, and overall durability. By developing new formulations and materials, manufacturers can produce tapes that meet specific needs in various environments.

2. Quality Control Ensuring product quality is paramount in the insulation tape manufacturing process. Manufacturers implement stringent quality control measures to test the performance of their tapes under various conditions. From temperature and humidity tests to adhesion and tensile strength evaluations, manufacturers must ensure that their products can withstand the challenges of the environments in which they are used.

3. Sustainability Practices In recent years, there has been a growing emphasis on sustainability within the manufacturing sector. Insulation tape manufacturers are increasingly exploring eco-friendly materials and practices. This includes using recyclable materials in the production process and minimizing waste. Manufacturers are also looking for ways to reduce their carbon footprint, contributing to global sustainability efforts.

insulation tape manufacturers

4. Customization Different industries have unique needs, and leading manufacturers recognize the importance of customization. Many manufacturers offer custom solutions tailored to the specifications required by their clients. This can include specific colors, widths, or material properties that suit particular applications.

Market Trends and Future Outlook

The global insulation tape market is expected to experience significant growth over the coming years. This growth is driven by several factors, including the expansion of renewable energy projects, increased construction activities, and the growing need for electrical insulation in automotive applications.

Renewable Energy The shift towards renewable energy sources such as wind and solar power is creating new opportunities for insulation tape manufacturers. These applications often require high-performance insulation solutions that can withstand harsh environmental conditions.

Electrification of Vehicles As electric and hybrid vehicles become more prevalent, the demand for reliable insulation materials will continue to rise. Insulation tape plays a vital role in the electrical systems of these vehicles, ensuring safety and performance.

Smart Technologies The rise of smart home technologies and Internet of Things (IoT) devices also contributes to the increased demand for insulation tape. As more electronic devices are interconnected, the need for effective insulation solutions becomes critical.

Conclusion

Insulation tape manufacturers are indispensable in ensuring the safety and reliability of electrical systems across various industries. With innovation and a commitment to quality, they continue to meet the ever-evolving needs of their clients. As the market grows, manufacturers who prioritize sustainability and customization will likely thrive in this competitive landscape. The future of insulation tape manufacturing appears bright, with ample opportunities for growth and development in the years to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025