Understanding the Role and Importance of Insulation Tape Manufacturers

Insulation tape is a crucial tool for various applications across industries, providing electrical insulation, protection, and a reliable means of bundling wires. The role of insulation tape manufacturers is fundamental in ensuring quality, safety, and efficiency in how consumers utilize these products. In this article, we will delve into the significance of insulation tape, the manufacturing processes involved, and the leading suppliers in the market.

The Importance of Insulation Tape

Insulation tape, often made from materials such as PVC, rubber, and cloth, serves multiple purposes. Primarily, it is used in electrical work to insulate wires and prevent short circuits. By covering exposed wires, insulation tape reduces the risk of electric shocks and protects against potential fire hazards. This makes it an indispensable tool in both residential and industrial electrical applications.

Furthermore, insulation tape provides mechanical protection against abrasion and moisture. Its adhesive properties allow it to bond effectively with various surfaces, making it useful in diverse environments. From automotive repairs to household wiring, the versatility of insulation tape cannot be overstated.

Manufacturing Processes of Insulation Tape

The manufacturing of insulation tape involves several stages, each critical in ensuring the final product meets industry standards. The process typically begins with the selection of raw materials. Manufacturers often choose high-quality polymers that can offer excellent electrical insulation properties while being resistant to heat and chemicals.

Once the materials are selected, the next step is compounding. This process involves mixing various additives with the polymer base to enhance specific properties such as adhesion, flexibility, and durability. The compounded material is then processed using techniques such as extrusion or casting to create the desired film thickness.

After the film is produced, it is coated with an adhesive layer on one side. The adhesive's formulation is vital, as it must provide a strong bond while allowing for easy application and removal. Different types of adhesives can be used based on the tape’s intended application, whether it be temporary or permanent.

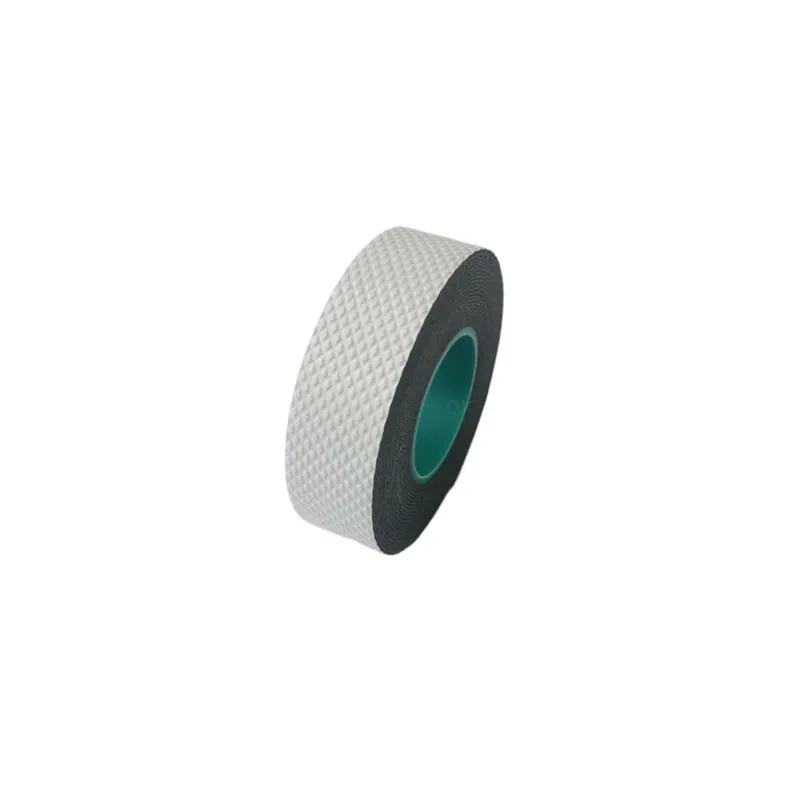

insulation tape manufacturers

Finally, the tape is cut into standard widths and rolled for packaging. Quality control is implemented at various stages of manufacturing to ensure that the tape meets specifications for thickness, adhesion strength, and electrical insulation performance. This rigorous process guarantees that insulation tape manufacturers deliver reliable products to their customers.

Leading Insulation Tape Manufacturers

Several manufacturers stand out in the insulation tape market, known for their commitment to quality and innovation. Companies like 3M,tesa, and Nitto are recognized globally for their advanced insulation solutions. These manufacturers invest heavily in research and development to create products that not only meet regulatory standards but also provide enhanced performance characteristics.

3M, for instance, is renowned for its extensive range of electrical insulation tapes designed for a variety of applications, from low-voltage to high-voltage systems. Their products are backed by years of expertise in materials science and engineering, ensuring their reliability.

Similarly, tesa specializes in high-performance insulation tapes that cater to both industrial and specialized applications. Their commitment to sustainability and environmental responsibility is evident in their product offerings, which increasingly include eco-friendly options.

Nitto, a global leader in adhesive technology, also excels in manufacturing insulation tape. With a focus on innovation, Nitto continuously develops new products that address the evolving needs of consumers in both the electrical and automotive sectors.

Conclusion

In conclusion, insulation tape manufacturers play a vital role in producing safe, effective, and high-quality adhesive tapes that are essential for a wide range of applications. As the demand for insulation tape grows, driven by advancements in technology and an increasing focus on safety, manufacturers are poised to lead the way in innovation. By understanding the intricacies of the manufacturing process and recognizing key industry players, consumers can make informed decisions when selecting products to meet their needs. Quality insulation tape is not just a convenience; it is a critical component in maintaining safety and efficiency in electrical systems worldwide.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025