Understanding Insulation Tape Types A Comprehensive Guide

Insulation tape, also known as electrical tape, is an essential material in various industries, including electrical, automotive, and construction. It serves as a protective barrier against electrical conductivity and environmental factors. However, not all insulation tapes are created equal; they come in various types, each designed for specific applications and requirements. This article delves into the different types of insulation tape, their properties, and suitable applications to help you make informed choices.

1. PVC Insulation Tape

Polyvinyl Chloride (PVC) insulation tape is one of the most commonly used types in electrical applications. It's known for its excellent flexibility, durability, and resistance to abrasion and moisture. PVC tape is typically used for insulating electrical wires, bundling cords, and repairing damaged electrical jackets. It's available in various colors, which not only helps in identification but also enhances safety by signaling different voltage levels. The temperature range for PVC tape typically ranges from -10°C to 80°C, making it suitable for indoor and moderate outdoor conditions.

2. Rubber Insulation Tape

Rubber insulation tape is designed for superior performance in high-voltage applications. Made from a synthetic rubber compound, this tape offers excellent insulating properties, as well as weather and chemical resistance. It's particularly useful in environments where temperatures might fluctuate drastically. Rubber tape is commonly used in electrical splicing and wrapping, providing a strong, moisture-resistant seal. It also has a higher elongation factor, allowing it to stretch and conform to irregular shapes easily.

3. Vinyl Electrical Tape

Similar to PVC tape, vinyl electrical tape is recognized for its insulating capabilities. Its unique formulation allows it to adhere well to various surfaces, making it ideal for wiring and electrical repairs. Vinyl tape is highly resistant to UV rays, chemicals, and solvents, making it suitable for both indoor and outdoor applications. Available in numerous colors, it also serves to communicate safety information effectively. This type of insulation tape usually operates within a temperature range of -10°C to 105°C.

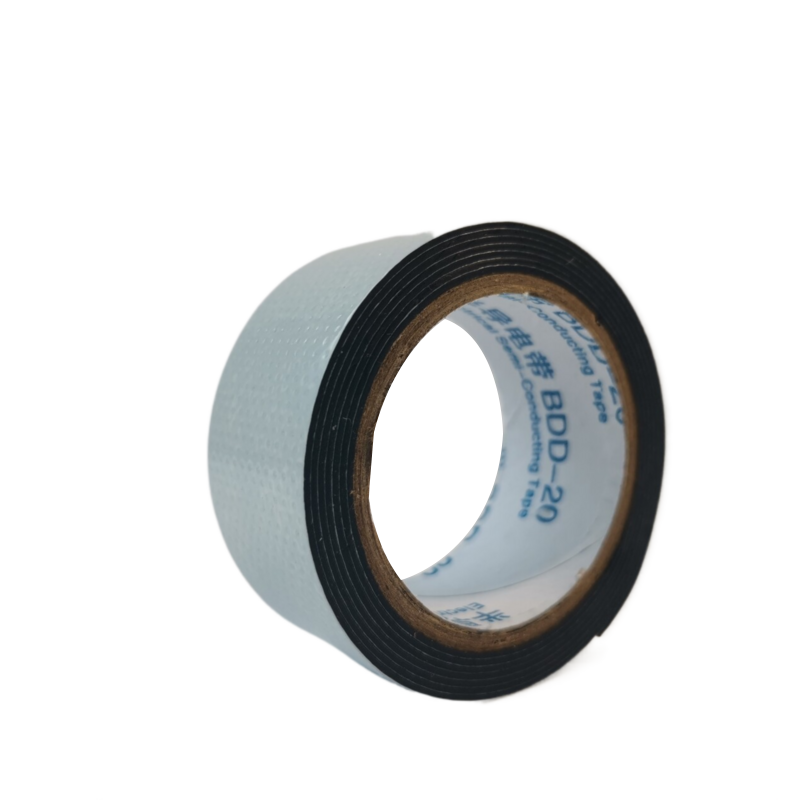

insulation tape types

4. High-Temperature Insulation Tape

High-temperature insulation tape is specifically engineered for environments where heat is a significant concern. This type of tape can withstand temperatures exceeding 200°C, making it suitable for use in industries like automotive and aerospace, where components may be exposed to extreme heat. The tape is often made from materials such as silicone or fiberglass, providing both thermal protection and electrical insulation. Applications include wrapping wire harnesses, insulating soldered connections, and heat shielding.

5. Self-Fusing Silicone Tape

Self-fusing silicone tape is a unique product that does not have an adhesive backing. Instead, it bonds to itself when stretched and wrapped around an object. This type of tape is exceptionally versatile and can be used to create watertight seals, protect electrical connections, and insulate wires. It is designed to withstand extreme temperatures and is resistant to UV rays, making it ideal for outdoor applications. Self-fusing silicone tape is especially beneficial in emergency repairs, as it can be applied quickly without the need for additional tools or adhesives.

6. Cloth Electrical Tape

Cloth electrical tape is primarily used in applications requiring a durable yet flexible insulating material. This type of tape is often made from a cloth backing coated with an adhesive, providing good insulation and mechanical protection. It is widely used for bundling wires, providing some level of protective covering, and even in creative applications like hobby crafts. This tape is less moisture-resistant than PVC or rubber but compensates with its ease of use and versatility.

Conclusion

When selecting insulation tape for your projects, it is crucial to consider the specific requirements of your application—including factors like temperature, environmental conditions, and electrical conductivity. Each type of insulation tape has its unique features and benefits, suitable for different scenarios. By understanding these variations, you can make informed decisions that ensure safety, efficiency, and durability in your electrical and repair projects. Whether you're an electrician, a DIY enthusiast, or a professional in another field, knowing the types of insulation tape available will empower you to choose the right tool for the job.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025