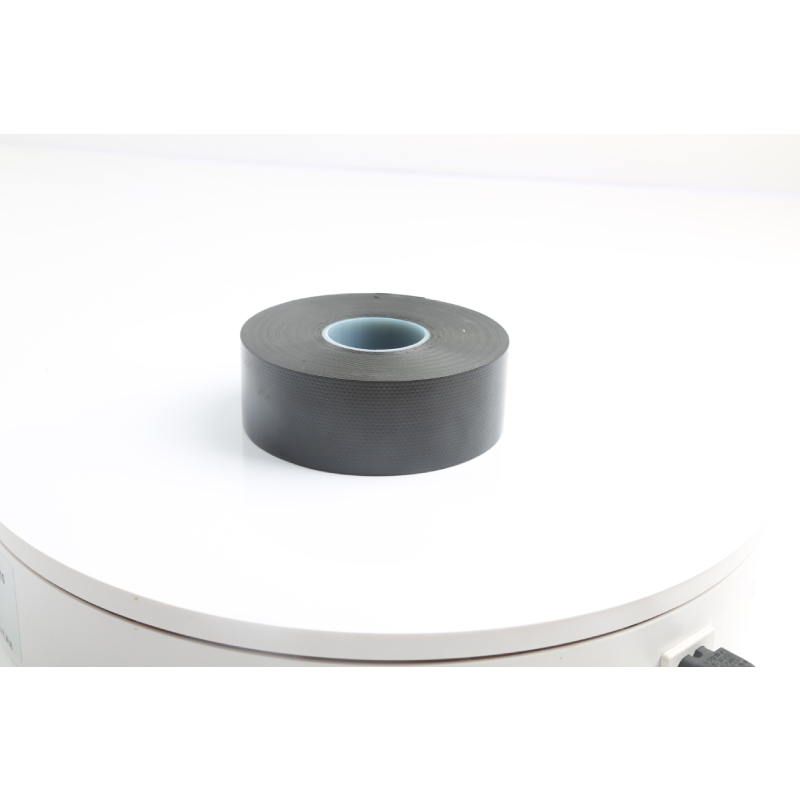

J50 High-voltage EPR Rubber Tape

Back to list

Jan . 10, 2025 09:17

Rubber splicing tape is a crucial component in various electrical applications, offering unparalleled experience and reliability for industry professionals. As experts in the field understand, this specialized tape is designed specifically to ensure robust insulation and performance in electrical splicing, especially in challenging environments.

Practical experience with rubber splicing tape highlights its ease of application, a critical factor for any professional looking to optimize their workflow. This self-fusing tape bonds quickly and securely to itself, eliminating the need for additional adhesives. This feature not only simplifies the installation process but also reduces the likelihood of installation errors, thereby enhancing the overall safety and reliability of electrical connections. Moreover, the elasticity of rubber splicing tape allows it to accommodate changes in cable dimensions due to thermal cycling, providing a consistent seal that prevents the ingress of moisture and contaminants. This adaptability ensures that the tape remains functional in fluctuating temperatures, a common challenge in outdoor electrical installations. In conclusion, rubber splicing tape remains a cornerstone in the toolbox of electrical professionals. Its combination of material excellence, proven reliability, and adherence to strict industry standards makes it an authoritative choice for those seeking effective and sustainable splicing solutions. As new innovations in material science continue to emerge, one can anticipate even greater enhancements in the performance and applications of rubber splicing tape, further solidifying its indispensable role in modern electrical engineering.

Practical experience with rubber splicing tape highlights its ease of application, a critical factor for any professional looking to optimize their workflow. This self-fusing tape bonds quickly and securely to itself, eliminating the need for additional adhesives. This feature not only simplifies the installation process but also reduces the likelihood of installation errors, thereby enhancing the overall safety and reliability of electrical connections. Moreover, the elasticity of rubber splicing tape allows it to accommodate changes in cable dimensions due to thermal cycling, providing a consistent seal that prevents the ingress of moisture and contaminants. This adaptability ensures that the tape remains functional in fluctuating temperatures, a common challenge in outdoor electrical installations. In conclusion, rubber splicing tape remains a cornerstone in the toolbox of electrical professionals. Its combination of material excellence, proven reliability, and adherence to strict industry standards makes it an authoritative choice for those seeking effective and sustainable splicing solutions. As new innovations in material science continue to emerge, one can anticipate even greater enhancements in the performance and applications of rubber splicing tape, further solidifying its indispensable role in modern electrical engineering.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025