The Rise of Electrical PVC Tape Manufacturers A Comprehensive Overview

In the world of electrical insulation and protection, PVC (Polyvinyl Chloride) tape has become an indispensable tool for both professionals and DIY enthusiasts. Versatile and reliable, electrical PVC tape is widely used in various applications, including electrical wiring, automotive repair, and construction projects. As demand for this essential product grows, so does the market for electrical PVC tape manufacturers, who are playing a crucial role in meeting the needs of consumers around the globe.

Understanding PVC Tape

Electrical PVC tape is known for its excellent insulating properties, making it the go-to choice for protecting electrical wires and connections. The tape is designed to withstand high voltages, resist moisture, and provide a durable solution to prevent accidental short circuits. Additionally, its flexibility allows for easy application around corners and irregular surfaces, which is essential for various wiring projects.

One of the key advantages of electrical PVC tape is its temperature resistance. It can operate effectively in a wide range of temperatures, making it suitable for both indoor and outdoor applications. Manufacturers produce various types of PVC tape, each designed for specific purposes, such as high-temperature insulation, color-coding wires, or even marking safety areas.

The Role of Manufacturers

The surge in the demand for electrical PVC tape has led to the emergence of numerous manufacturers across the globe. These companies range from large-scale industrial producers to small niche players. The rise of e-commerce has also made it easier for new manufacturers to enter the market and reach a broader audience.

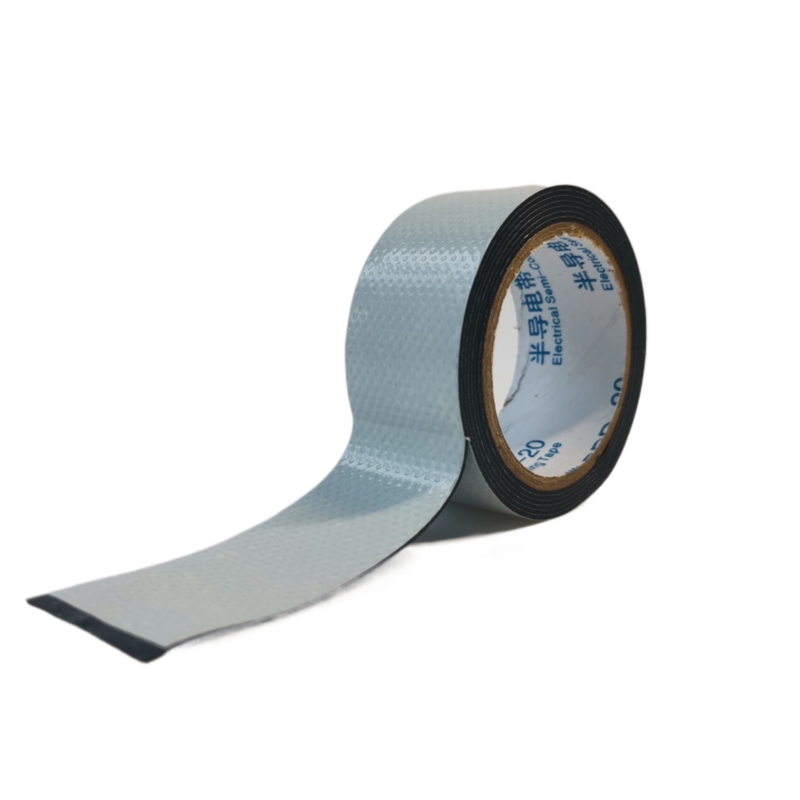

electrical pvc tape manufacturers

Manufacturers focus on several critical factors to ensure their products meet or exceed industry standards. Quality control is paramount; rigorous testing is conducted to verify that the tape adheres to electrical safety regulations. This includes assessments of tensile strength, elongation, moisture resistance, and temperature tolerance. By adhering to these standards, manufacturers can guarantee the performance and reliability of their products.

Innovation and Sustainability

The electrical PVC tape industry is not stagnant; innovation is at the forefront as manufacturers seek to improve their products continuously. With increasing awareness of environmental sustainability, many manufacturers are exploring eco-friendly materials and production processes. Some companies are developing PVC tapes that utilize recycled materials or are designed to be biodegradable, aligning with the global push towards sustainability.

Additionally, advancements in technology have led to improved manufacturing techniques. Automation and mechanization have streamlined production processes, allowing manufacturers to increase output while maintaining high quality. This efficiency is crucial as the global demand for electrical PVC tape continues to rise, driven by sectors such as renewable energy, construction, and automotive industries.

Market Trends and Future Outlook

As the world becomes increasingly electrified, the demand for electrical PVC tape is expected to grow. Infrastructure projects and the installation of renewable energy sources, such as solar panels and wind turbines, necessitate robust insulation solutions. Moreover, the rise of electric vehicles (EVs) is opening up new avenues for PVC tape manufacturers to supply products tailored for the automotive market.

In conclusion, electrical PVC tape manufacturers are essential players in the global electrical supply chain. Their contributions to quality, innovation, and sustainability enhance the reliability of electrical systems while meeting the evolving needs of various industries. As technology advances and markets expand, these manufacturers will continue to reshape the landscape of electrical insulation solutions, ensuring safety and efficiency in an ever-modernizing world.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025