Understanding Linerless Rubber Splicing Tape A Versatile Solution for Various Applications

Linerless rubber splicing tape is an innovative product that has gained popularity in various industries for its practical applications and efficiency. This type of tape is notable for its unique design and the absence of a liner, allowing for easier handling and application. By exploring its features, benefits, and uses, we can better understand why linerless rubber splicing tape is an essential tool in many fields.

What is Linerless Rubber Splicing Tape?

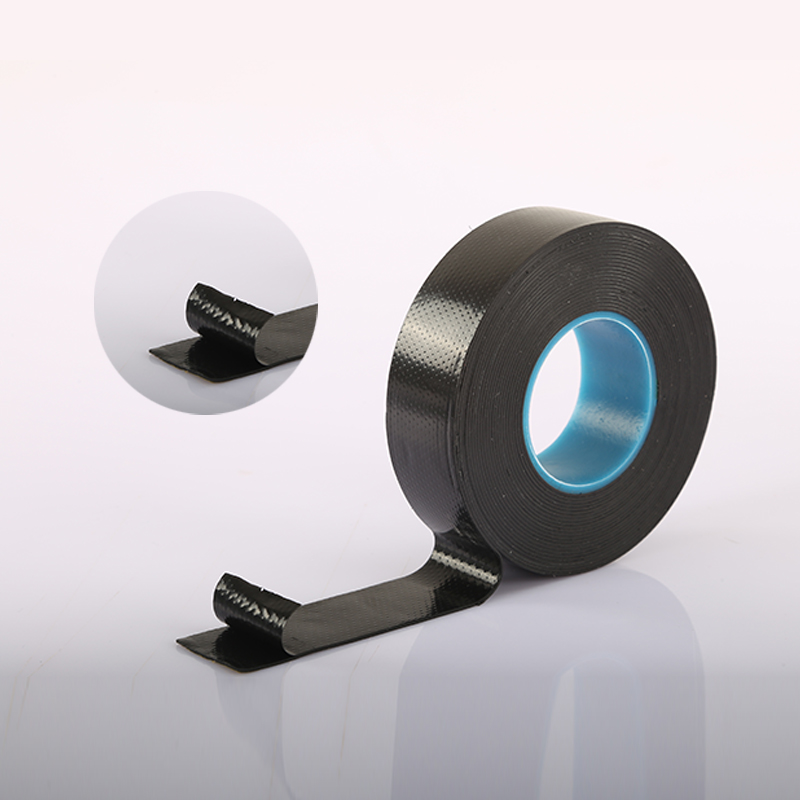

Linerless rubber splicing tape is a self-fusing, pressure-sensitive tape made from a blend of high-quality rubber compounds. The notable absence of a protective liner distinguishes it from traditional adhesive tapes. Instead of peeling off a liner, users can apply it directly to surfaces, making the process quicker and smoother. This type of tape is designed for splicing wires, insulating electrical connections, and providing moisture protection in various environments.

Key Features

1. Self-Fusing One of the standout features of linerless rubber splicing tape is its self-fusing property. When wrapped around an object, the tape bonds to itself, creating a strong, waterproof seal. This eliminates the need for adhesives or additional bonding agents, simplifying the application process.

2. High Voltage and Temperature Resistance Linerless rubber splicing tape is engineered to withstand high voltage levels and temperatures, making it suitable for use in various industries, including electrical, automotive, and aerospace. Its durability and performance in extreme conditions ensure reliable insulation and protection.

3. Flexibility and Conformability The tape's elastic properties allow it to conform to irregular surfaces, providing comprehensive coverage. This feature is particularly beneficial when working with complex geometries in electrical systems or when sealing irregular joints.

4. Chemical Resistance Linerless rubber splicing tape has inherent chemical resistance, making it suitable for applications in environments where exposure to oils, solvents, and other chemicals is common. This quality helps maintain the integrity of the seal over time.

Benefits of Using Linerless Rubber Splicing Tape

The advantages of using linerless rubber splicing tape are multifaceted and cater to various needs in diverse industries

- Ease of Use The absence of a liner allows for straightforward application without cumbersome prep work

. Users can cut and apply the tape quickly, making it ideal for time-sensitive projects.linerless rubber splicing tape

- Reduced Waste By eliminating the need for a liner, this tape significantly reduces waste, making it a more environmentally friendly choice compared to traditional adhesive tapes.

- Enhanced Performance The self-fusing characteristic ensures that the tape forms a lasting bond, providing superior insulation and protection against moisture and abrasion. This leads to increased reliability and longevity of electrical and mechanical systems.

- Cost-Effectiveness Given its durability and performance, linerless rubber splicing tape often proves to be a cost-effective solution. Fewer replacements and repairs are necessary, ultimately saving time and money.

Applications

Linerless rubber splicing tape is utilized across various sectors, including

- Electrical Work Ideal for insulating splices in electrical cables and connections, preventing short circuits and ensuring safe operation.

- Automotive Maintenance Used to repair wiring harnesses and other components, providing water and abrasion resistance in vehicles.

- HVAC Systems Effective in sealing ductwork and insulation, helping to maintain energy efficiency and prevent airflow loss.

- Aerospace Engineering Employed in harnessing applications and to protect sensitive components from moisture and environmental factors.

Conclusion

In summary, linerless rubber splicing tape offers a range of benefits that cater to diverse industrial needs. Its ease of use, reliability, and performance make it an indispensable tool for professionals across various fields. As industries continue to evolve and innovate, the demand for practical solutions like linerless rubber splicing tape is expected to grow, solidifying its place as a go-to choice for effective splicing and insulation tasks. Whether in electrical applications, automotive repairs, or aerospace engineering, this tape stands out as a versatile and essential resource.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025