Understanding Linerless Rubber Tape A Versatile Solution for Various Applications

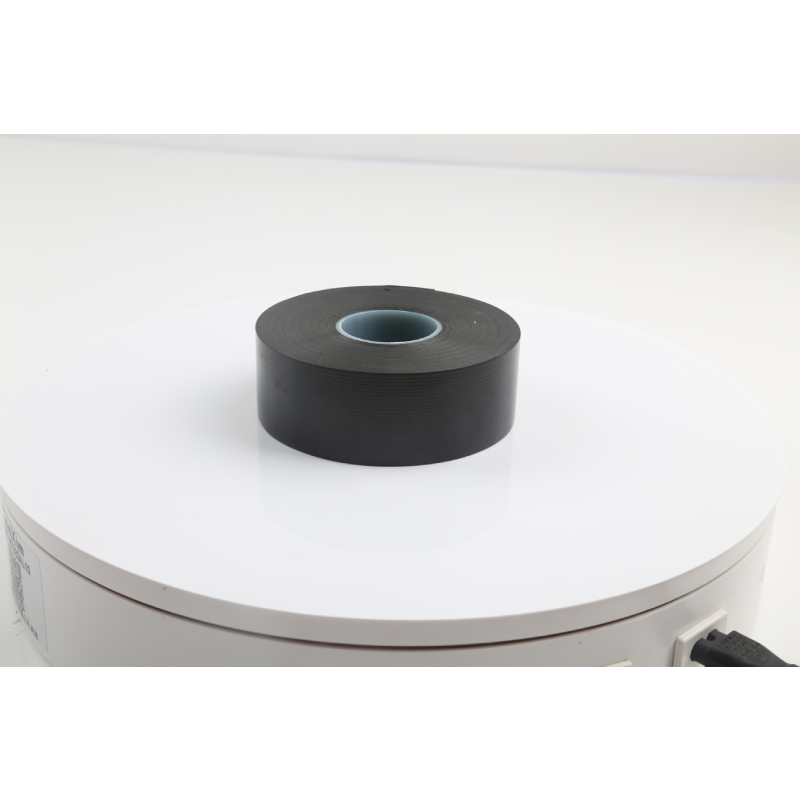

Linerless rubber tape is an innovative adhesive solution that has gained popularity across various industries due to its unique properties and versatile applications. Unlike traditional tapes that come with a backing or liner, linerless rubber tape utilizes a self-adhesive design, allowing for easy application and minimal waste. This feature is particularly advantageous in terms of both efficiency and cost-effectiveness.

One of the standout characteristics of linerless rubber tape is its excellent adhesion capabilities. Made from high-quality rubber, this tape adheres well to a wide range of surfaces, including metal, wood, plastic, and glass. This versatility makes it an ideal choice for construction, repair, and DIY projects where reliable bonding is essential. It can be used to seal joints, provide insulation, or even protect surfaces from abrasion and moisture.

Furthermore, linerless rubber tape is resistant to extreme temperatures, making it suitable for both indoor and outdoor applications. Whether used in harsh weather conditions or in areas with fluctuating temperatures, this tape maintains its integrity and performance. It is also resistant to UV rays, which is particularly important for outdoor applications where exposure to sunlight can degrade other types of adhesives.

linerless rubber tape

Another significant advantage of linerless rubber tape is its ease of use. Without a liner to peel away, users can simply cut to the desired length and apply the tape directly to the surface. This contributes to a more efficient workflow, especially in industrial settings where time is of the essence. Additionally, the ability to apply the tape without needing to remove a backing means reduced waste, aligning with the increasing demand for sustainable and environmentally friendly practices in manufacturing and construction.

In the electrical industry, linerless rubber tape shines as an excellent insulation material. Its dielectric properties make it a reliable choice for insulating wires and electrical components, ensuring safety and reducing the risk of short circuits. This aspect has made it a favored option among electricians and technicians who require dependable insulation in their work.

Moreover, the adhesive properties of linerless rubber tape can withstand mechanical stress and environmental factors, further enhancing its applicability in various contexts. Whether used in automotive repairs, HVAC applications, or general maintenance tasks, this tape provides a robust and durable solution.

In conclusion, linerless rubber tape is a remarkable adhesive product that offers a combination of strength, versatility, and convenience. Its ability to conform to different surfaces, coupled with its resistance to temperature and UV exposure, makes it an invaluable tool for professionals and DIY enthusiasts alike. As industries continue to evolve, the demand for efficient and effective adhesive solutions like linerless rubber tape is likely to increase, solidifying its place as a staple in both industrial and consumer markets.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025