Liquid Rubber Electrical Insulation An Overview

In today's fast-paced technological world, effective electrical insulation is crucial for ensuring safety, efficiency, and longevity in various electrical and electronic applications. One innovative solution that has gained traction in recent years is liquid rubber electrical insulation. This material offers unique properties that make it highly suitable for a range of uses, from household appliances to industrial machinery and outdoor electrical components.

What is Liquid Rubber?

Liquid rubber is a versatile material that belongs to the category of synthetic elastomers. It is typically composed of polymer compounds that can be applied in a liquid state, which then cure into a durable, flexible membrane. This curing process creates a tough, seamless barrier that protects electrical components from environmental factors such as moisture, dust, and extreme temperatures. Unlike traditional solid insulators, liquid rubber can conform to mixed geometries and is ideal for complex shapes and surfaces.

Benefits of Liquid Rubber Electrical Insulation

1. Superior Protection Against Environmental Factors One of the most significant advantages of liquid rubber insulation is its ability to provide robust protection against harsh environmental conditions. It forms a waterproof and airtight seal that prevents moisture ingress, which is particularly important for outdoor electrical installations exposed to rain and humidity. Additionally, liquid rubber is highly resistant to UV radiation, ensuring that it can withstand prolonged exposure to sunlight without degrading.

2. Flexibility and Conformability Liquid rubber has a high degree of elasticity, allowing it to stretch and conform to irregular surfaces. This property makes it ideal for insulating components with complex shapes or surfaces that traditional rigid insulators cannot adequately cover. This flexibility not only simplifies the application process but also enhances the durability of the insulation by reducing stress points that can lead to cracks or leaks over time.

3. Chemical Resistance In many industrial applications, electrical components are exposed to various chemicals and solvents. Liquid rubber insulation exhibits excellent resistance to a wide range of chemical agents, making it a preferred choice for applications in industries such as automotive, aerospace, and manufacturing. This resistance helps ensure that the insulation maintains its integrity and performance over an extended period.

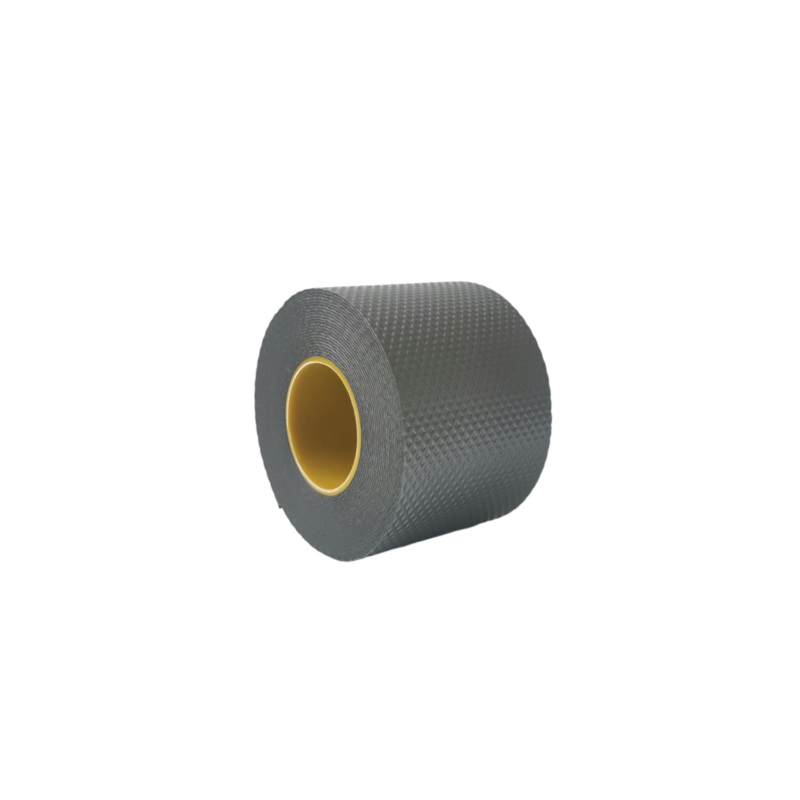

liquid rubber electrical insulation

4. Easy Application Liquid rubber can be applied using several methods, including brush, spray, or pour techniques, making it convenient for a variety of applications. Its liquid state allows for an even and thorough coating, ensuring full coverage of the surface and eliminating the concerns of gaps or bubbles that may occur with traditional insulation materials. Additionally, it cures quickly, allowing for faster project completion and minimizing downtime.

Applications of Liquid Rubber Electrical Insulation

Liquid rubber electrical insulation is utilized in various applications across multiple industries. In the construction sector, it is employed to protect wiring and electrical connections in buildings and outdoor structures. In automotive applications, it helps shield electrical components from moisture and heat, enhancing vehicle reliability and safety.

Moreover, liquid rubber insulation finds applications in consumer electronics, protecting delicate internal circuits from damage due to environmental factors. In telecommunications, it provides insulation for outdoor cables and components, ensuring uninterrupted service. Additionally, it is used in renewable energy systems, such as solar panels and wind turbines, to protect electrical components operating in challenging environments.

Conclusion

Liquid rubber electrical insulation represents a significant advancement in the field of electrical insulation, combining flexibility, durability, and excellent environmental protection. As industries continue to innovate and evolve, the importance of reliable and effective electrical insulation cannot be overstated. With its myriad benefits and diverse applications, liquid rubber insulation is poised to play an essential role in the future of electrical engineering, providing safe and efficient solutions in an increasingly complex technological landscape.

In summary, the use of liquid rubber for electrical insulation offers a multitude of advantages over traditional materials. As manufacturers and engineers seek to improve the reliability and performance of electrical systems, liquid rubber stands out as a solution that not only meets but exceeds modern insulation demands, ensuring that technology continues to advance in a safe and sustainable manner.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025