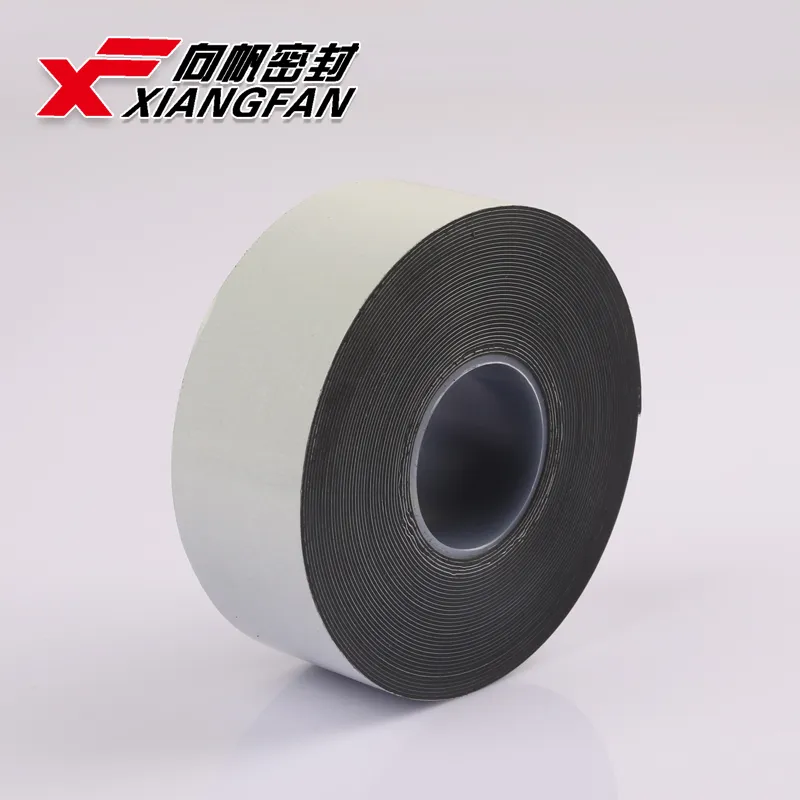

neoprene pipe insulation wrap

Back to list

Feb . 14, 2025 00:05

Neoprene pipe insulation wrap serves as a crucial component in effective thermal management systems across various industries. As an experienced SEO specialist, I understand that what's pivotal for web users and industry professionals alike is a comprehensive understanding of its application, benefits, and selection criteria. This article serves as an authoritative guide, drawing from real-world experiences and professional expertise to bolster trust and reliability.

From an expert perspective, the selection of neoprene pipe insulation wraps should factor in thickness and jacket type relative to specific application needs. Thicker wraps generally provide superior insulation, essential for high-temperature pipes or those running through cold environments. The choice of jacket can further enhance performance, with optional features such as UV-resistant coatings for outdoor installations or antimicrobial treatments in sanitary environments. These enhancements contribute to neoprene’s versatility, firmly entrenching its status as a favored choice among professionals across various sectors. The process of installing neoprene pipe insulation is straightforward, an attribute often emphasized in feedback from field engineers. Its flexibility allows for easy handling and fitting around pipes of complex shapes, reducing labor time and thus expense. Quick and effective installation, paired with its low maintenance requirements, has been highlighted by contractors evaluating insulation wraps over extended operational periods. Trustworthiness in product performance is further underlined by compliance with industry standards, which neoprene insulation typically meets or exceeds. Whether it’s ASHRAE recommendations for energy efficiency or ASTM standards for material performance, neoprene’s adherence to stringent criteria reassures users of its reliability. This compliance underscores the importance of choosing reputable manufacturers and suppliers who guarantee their products meet these standards. In conclusion, neoprene pipe insulation wrap stands out in the realm of pipe insulation solutions. Its combination of thermal efficiency, durability, and ease of use make it a preferred choice among professionals looking for long-term reliability and value. In sharing these insights, drawn from direct experience and industry expertise, this article aims to provide the authoritative guidance needed to make informed decisions about pipe insulation needs. For those seeking to enhance system performance through effective pipe insulation, neoprene offers a time-tested solution trusted by industries worldwide.

From an expert perspective, the selection of neoprene pipe insulation wraps should factor in thickness and jacket type relative to specific application needs. Thicker wraps generally provide superior insulation, essential for high-temperature pipes or those running through cold environments. The choice of jacket can further enhance performance, with optional features such as UV-resistant coatings for outdoor installations or antimicrobial treatments in sanitary environments. These enhancements contribute to neoprene’s versatility, firmly entrenching its status as a favored choice among professionals across various sectors. The process of installing neoprene pipe insulation is straightforward, an attribute often emphasized in feedback from field engineers. Its flexibility allows for easy handling and fitting around pipes of complex shapes, reducing labor time and thus expense. Quick and effective installation, paired with its low maintenance requirements, has been highlighted by contractors evaluating insulation wraps over extended operational periods. Trustworthiness in product performance is further underlined by compliance with industry standards, which neoprene insulation typically meets or exceeds. Whether it’s ASHRAE recommendations for energy efficiency or ASTM standards for material performance, neoprene’s adherence to stringent criteria reassures users of its reliability. This compliance underscores the importance of choosing reputable manufacturers and suppliers who guarantee their products meet these standards. In conclusion, neoprene pipe insulation wrap stands out in the realm of pipe insulation solutions. Its combination of thermal efficiency, durability, and ease of use make it a preferred choice among professionals looking for long-term reliability and value. In sharing these insights, drawn from direct experience and industry expertise, this article aims to provide the authoritative guidance needed to make informed decisions about pipe insulation needs. For those seeking to enhance system performance through effective pipe insulation, neoprene offers a time-tested solution trusted by industries worldwide.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025