The Growing Demand for PVC Electrical Tape A Look into the Factory Production

In recent years, the electrical industry has witnessed a surge in demand for reliable and efficient insulation materials. Among these, PVC (Polyvinyl Chloride) electrical tape stands out due to its robust insulation properties, flexibility, and versatility. As the world becomes increasingly electrified, the production of PVC electrical tape has become a critical function in manufacturing facilities worldwide. This article explores the significance of PVC electrical tape factories and the production intricacies that make this essential product.

Understanding PVC Electrical Tape

PVC electrical tape is an insulating tape made from polyvinyl chloride material, known for its excellent electrical insulation properties. It is widely utilized in various applications, including household wiring, automotive repairs, and industrial setups. The tape is designed to withstand high temperatures and resist chemicals, moisture, and abrasion, making it suitable for numerous environments.

The tape itself is available in various colors, allowing for color coding in wiring systems, which enhances safety and organization. Furthermore, its elasticity promotes easy application around corners and in tight spaces, making it a favorite among electricians and DIY enthusiasts alike.

The Production Process in Factories

The manufacturing of PVC electrical tape involves several key steps, all of which are essential for ensuring the product’s quality and reliability. Here’s an overview of the common stages in a PVC electrical tape factory

1. Raw Material Sourcing The primary materials required for PVC electrical tape production are polyvinyl chloride, plasticizers, and numerous additives to enhance performance attributes, such as flame retardancy and UV resistance. Factories source these materials from credible suppliers to guarantee quality.

2. Mixing and Compounding The raw materials are blended in precise proportions to achieve the desired tape characteristics. This process can include heating and mechanical mixing to ensure a uniform consistency. Additives are included in this stage to further enhance the tape’s properties and effectiveness.

pvc electrical tape factory

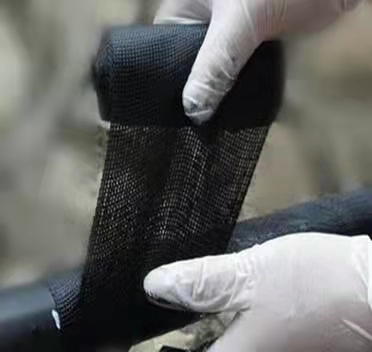

3. Extrusion Once the compound is prepared, it is fed into an extrusion machine where it is melted and formed into a thin film. This film is crucial for producing the flexible, durable layer that characterizes high-quality PVC electrical tape.

4. Coating and Drying Next, the extruded PVC film is coated with a layer of adhesive. The adhesive must be strong enough to ensure that the tape sticks securely to surfaces, yet removable without leaving a residue. Following the coating, the tape is passed through a drying stage to cure the adhesive and finalize the product.

5. Cutting and Packaging After the tape is dried, it is wound onto spools or rolls and cut to various lengths depending on customer requirements. Quality control checks are conducted to ensure the product meets specified standards before packaging it for distribution.

6. Distribution Finally, the finished product is packaged and shipped to distributors, retailers, and directly to customers. Factories often maintain a robust inventory system to meet fluctuating demands effectively.

The Eco-Conscious Shift

As sustainability becomes a focal point in global manufacturing practices, PVC electrical tape factories are also adopting eco-friendly initiatives. This includes the use of recycled materials in production, reducing waste, and minimizing energy consumption during manufacturing processes. Such shifts not only align factories with modern environmental standards but also appeal to eco-conscious consumers.

Conclusion

The significance of PVC electrical tape factories cannot be overstated. They play a vital role in providing essential insulation products that cater to an ever-growing demand for safety and efficiency in electrical applications. As technologies evolve and industries continue to electrify, the production of PVC electrical tape will remain a cornerstone in ensuring electrical systems are safe, reliable, and well insulated. Whether it’s in a home, vehicle, or industrial plant, the humble PVC electrical tape proves indispensable in the modern world.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025