Understanding PVC Insulation Tape Manufacturers The Key to Quality and Reliability

In today’s industrial landscape, PVC (Polyvinyl Chloride) insulation tape plays a crucial role in a variety of applications, making it an essential product for electricians, construction workers, and manufacturers alike. With its excellent insulating properties, durability, and versatility, PVC insulation tape is widely used in electrical wiring, automotive applications, and general repairs. However, the quality of insulation tape can vary significantly among different manufacturers, which is why selecting a dependable supplier is critical.

The Importance of Insulation Tape

PVC insulation tape is designed to provide electrical insulation, moisture resistance, and protection against abrasions. Its resistance to heat and chemicals makes it ideal for a range of environments, from home improvement projects to large-scale industrial operations. The ability of this tape to stretch and conform to surfaces further enhances its application, ensuring secure and effective insulation when wrapped around wires and electrical components.

The demand for PVC insulation tape has surged due to increased construction activities, advancements in electrical systems, and a growing focus on safety standards. Consequently, the market has seen an influx of manufacturers, each claiming to provide the best products. This has made it essential for buyers to understand the factors that differentiate reputable manufacturers from lesser-known entities.

Factors to Consider When Choosing a Manufacturer

1. Quality of Raw Materials The manufacturing process begins with the selection of raw materials. Trusted manufacturers utilize high-quality PVC resin, ensuring that the final product meets industry standards for strength, flexibility, and insulating properties. Buyers should inquire about the sourcing of materials and the manufacturer's commitment to quality control.

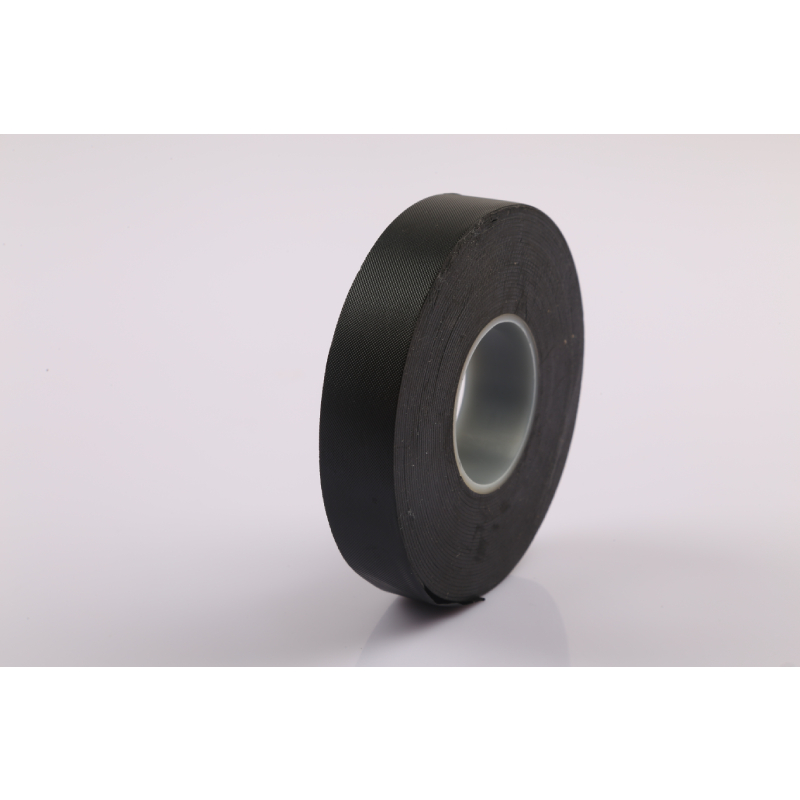

pvc insulation tape manufacturers

2. Manufacturing Process A reliable manufacturer will have a well-defined production process that adheres to international standards. This includes investing in advanced machinery and technology to enhance precision and consistency. Additionally, manufacturers should follow stringent testing protocols to verify the performance of their products.

3. Certifications and Standards Certifications from recognized organizations (such as ISO, RoHS, or UL) serve as indicators of a manufacturer’s commitment to quality and safety. These certifications ensure that the products adhere to specific regulations and can be trusted in critical applications.

4. Product Range A manufacturer that offers a comprehensive range of PVC insulation tape products demonstrates versatility and expertise in the field. Options such as different colors, widths, and adhesive strengths can cater to varied customer requirements, making it easier for buyers to find the perfect tape for their needs.

5. Customer Service and Support Effective communication and customer support are vital when dealing with manufacturers. A responsive team that can address inquiries, provide guidance on product selection, and assist with issues can enhance the overall buying experience.

6. Feedback and Reviews It’s wise for buyers to research customer reviews and feedback about various manufacturers. Positive testimonials from previous clients can provide insights into the reliability and quality of the products offered.

Conclusion

In conclusion, the landscape of PVC insulation tape manufacturers is vast, with numerous options available to consumers. However, the importance of choosing the right manufacturer cannot be overstated. By prioritizing quality materials, robust manufacturing processes, established certifications, a diverse product range, and reliable customer support, buyers can ensure they select a manufacturer capable of meeting their insulation tape needs effectively. Investing time in research and due diligence when choosing a supplier will ultimately lead to better project outcomes and enhance safety and reliability in electrical applications. As industries continue to evolve, the role of high-quality PVC insulation tape will remain indispensable, making the selection of trustworthy manufacturers more critical than ever.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025