price pvc tape for electrical insulation

Back to list

Feb . 19, 2025 07:27

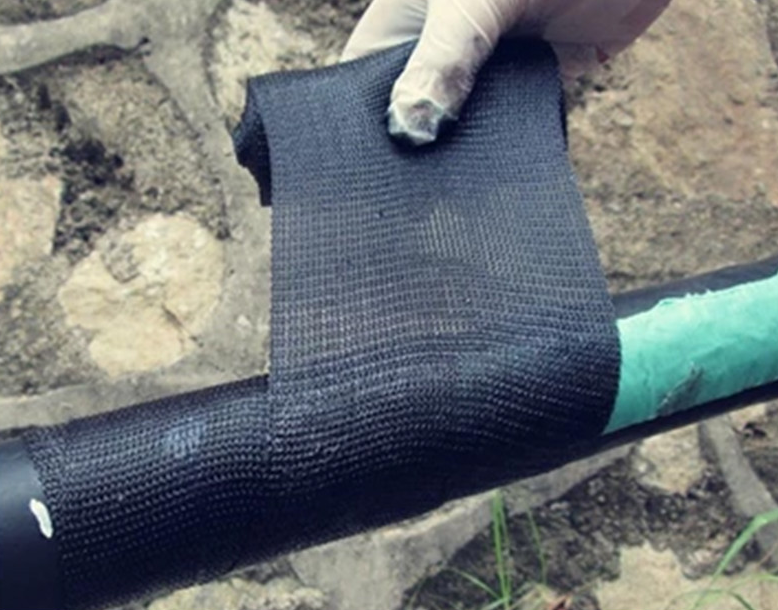

PVC insulation tape is a staple product in diverse industries, serving purposes from electrical insulation to bundling cables and other applications. Understanding the cost dynamics of PVC insulation tape can provide businesses and consumers with strategic insights for making informed purchasing decisions. To navigate the market effectively, it's essential to assess factors influencing pricing, including material quality, brand reputation, and market demand.

Bulk purchasing is a strategic approach to consider for obtaining more favorable pricing on PVC insulation tape. Suppliers often offer tiered pricing models, providing discounts for larger orders. This not only lowers the cost per unit but also secures a consistent supply for businesses reliant on PVC tape for daily operations, adding a layer of financial predictability. The role of evolving technology in manufacturing processes cannot be overlooked when assessing prices. Advances in producing high-performance tape with reduced environmental impact are increasingly valued. Tapes that are more eco-friendly may come at a higher price due to the refined technology and processes involved but represent a commitment to sustainability that many businesses and consumers are willing to invest in. In terms of consumer experience, testimonials and reviews from industry experts and actual users provide vital insights into the real-world performance and value for money offered by different PVC insulation tapes. Platforms allowing for this exchange of information contribute significantly to building trust and confidence in purchasing decisions. Peer reviews often highlight aspects like ease of use, weather resistance, and adhesive longevity that influence perceived value and, consequently, pricing strategies from suppliers. In conclusion, the price of PVC insulation tape is determined by a multitude of factors including material quality, brand reputation, compliance with industry standards, market demand, economic conditions, and emerging technological advancements. Buyers benefit from a deep understanding of these factors, allowing them to make educated purchasing choices that align with their needs and budgets. Trust in established brands and their expertise can often mitigate risks associated with lower-cost alternatives, especially in applications where safety and performance are paramount.

Bulk purchasing is a strategic approach to consider for obtaining more favorable pricing on PVC insulation tape. Suppliers often offer tiered pricing models, providing discounts for larger orders. This not only lowers the cost per unit but also secures a consistent supply for businesses reliant on PVC tape for daily operations, adding a layer of financial predictability. The role of evolving technology in manufacturing processes cannot be overlooked when assessing prices. Advances in producing high-performance tape with reduced environmental impact are increasingly valued. Tapes that are more eco-friendly may come at a higher price due to the refined technology and processes involved but represent a commitment to sustainability that many businesses and consumers are willing to invest in. In terms of consumer experience, testimonials and reviews from industry experts and actual users provide vital insights into the real-world performance and value for money offered by different PVC insulation tapes. Platforms allowing for this exchange of information contribute significantly to building trust and confidence in purchasing decisions. Peer reviews often highlight aspects like ease of use, weather resistance, and adhesive longevity that influence perceived value and, consequently, pricing strategies from suppliers. In conclusion, the price of PVC insulation tape is determined by a multitude of factors including material quality, brand reputation, compliance with industry standards, market demand, economic conditions, and emerging technological advancements. Buyers benefit from a deep understanding of these factors, allowing them to make educated purchasing choices that align with their needs and budgets. Trust in established brands and their expertise can often mitigate risks associated with lower-cost alternatives, especially in applications where safety and performance are paramount.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025