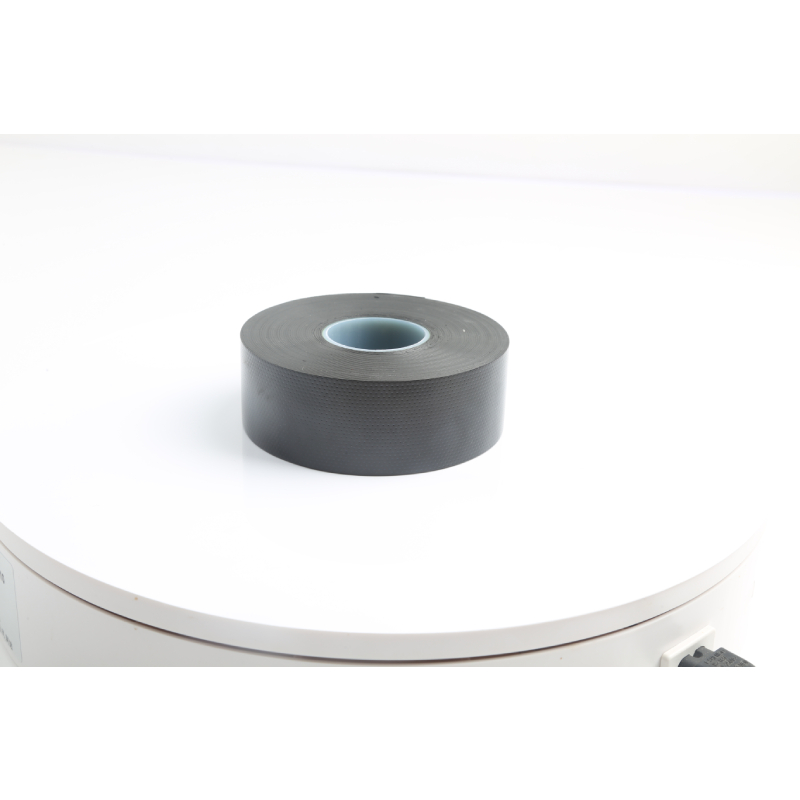

pvc tape

Back to list

Feb . 11, 2025 13:42

PVC tape, a versatile and essential tool in various industries, has significantly evolved in terms of material quality, usage, and performance. Recognized for its adaptability and durability, PVC tape is an indispensable component in the construction, electrical, and packaging sectors. This article delves into the unique features and applications of PVC tape, emphasizing its unparalleled benefits and innovative attributes that set it apart from other adhesive solutions.

The expertise behind PVC tape's development highlights advancements in material science and adhesive technology. Studies indicate that the integration of superior plasticizers in PVC enhances its elasticity, thereby improving its performance in both hot and cold environments. This adaptability is crucial for industries requiring tailored adhesive solutions that perform consistently across various temperatures and humidity levels. From an authoritative perspective, the production of PVC tape adheres to stringent industry standards, ensuring safety and quality. Manufacturers often subject the tape to rigorous testing, assessing its tensile strength, adhesion properties, and resistance to aging. These quality checks guarantee that the end product not only meets the specified requirements but also exceeds user expectations. The trustworthiness of PVC tape is further solidified by certifications from recognized bodies, endorsing its usage in critical applications where safety and reliability are paramount. In conclusion, PVC tape stands out as a remarkable product, revered for its exceptional performance across numerous domains. Its unique composition, coupled with rigorous testing and adherence to industry standards, makes it a reliable choice for professionals seeking durable and efficient adhesive solutions. Whether for construction, electrical, or packaging purposes, PVC tape delivers unmatched quality and adaptability, reflecting both expertise and innovation in its design and application. As industries continue to demand higher standards of performance and safety, PVC tape consistently rises to the occasion, embodying the principles of experience, expertise, authoritativeness, and trustworthiness. This makes it not just an adhesive tool, but a pivotal asset in modern industry practices.

The expertise behind PVC tape's development highlights advancements in material science and adhesive technology. Studies indicate that the integration of superior plasticizers in PVC enhances its elasticity, thereby improving its performance in both hot and cold environments. This adaptability is crucial for industries requiring tailored adhesive solutions that perform consistently across various temperatures and humidity levels. From an authoritative perspective, the production of PVC tape adheres to stringent industry standards, ensuring safety and quality. Manufacturers often subject the tape to rigorous testing, assessing its tensile strength, adhesion properties, and resistance to aging. These quality checks guarantee that the end product not only meets the specified requirements but also exceeds user expectations. The trustworthiness of PVC tape is further solidified by certifications from recognized bodies, endorsing its usage in critical applications where safety and reliability are paramount. In conclusion, PVC tape stands out as a remarkable product, revered for its exceptional performance across numerous domains. Its unique composition, coupled with rigorous testing and adherence to industry standards, makes it a reliable choice for professionals seeking durable and efficient adhesive solutions. Whether for construction, electrical, or packaging purposes, PVC tape delivers unmatched quality and adaptability, reflecting both expertise and innovation in its design and application. As industries continue to demand higher standards of performance and safety, PVC tape consistently rises to the occasion, embodying the principles of experience, expertise, authoritativeness, and trustworthiness. This makes it not just an adhesive tool, but a pivotal asset in modern industry practices.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025