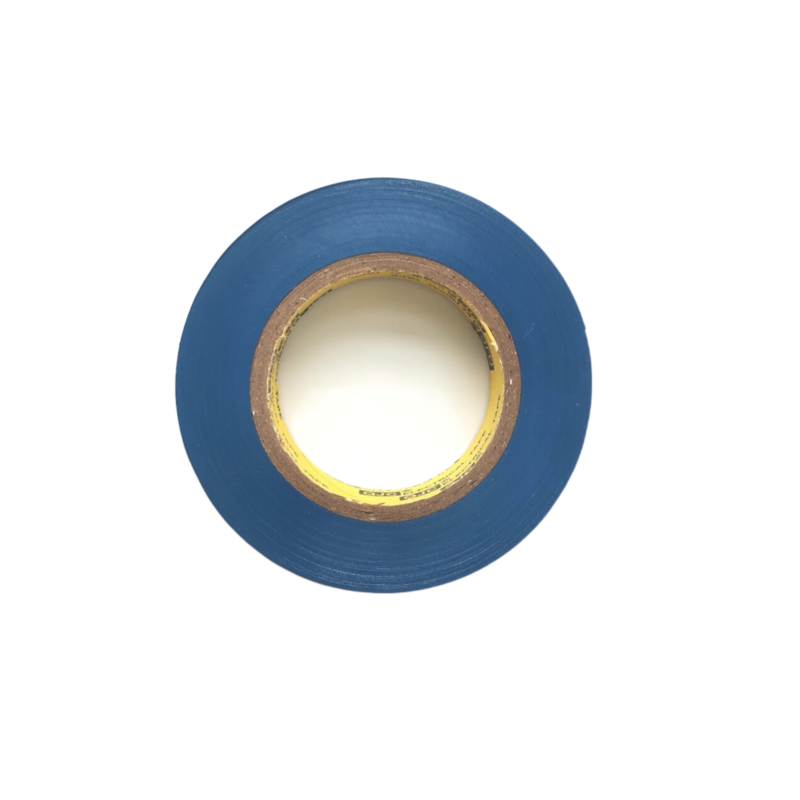

fiberglass tape for electrical insulation

Back to list

Feb . 17, 2025 12:08

When considering improvements to safety and efficiency in both professional and amateur electrical projects, red insulation tape holds a pivotal role. This unassuming yet essential item can make or break the success of electrical installations, and it's crucial to understand its capabilities, uses, and advantages from a first-hand perspective.

From a technical angle, the ease of application is another element that sets high-quality red insulation tape apart. Users will appreciate the smooth unrolling and effortless tearing, which makes the tape ideal for intricate projects that require precise insulation coverage. Over the years, feedback from both novices and seasoned electricians consistently highlights that a user-friendly product drastically reduces installation time and minimizes errors. Trustworthiness is another critical factor. Red insulation tape serves as an industry standard in distinguishing live wires. In environments shared by multiple trades, such as construction sites, consistent color coding is paramount in maintaining safety standards. The authoritative role of this practice is underscored in electrical regulations globally, reinforcing the tape’s indispensable status on both safety and regulatory fronts. Furthermore, from a cost-efficiency standpoint, red insulation tape serves as an economical solution. Compared to replacement costs and the potential fallout from electrical failures, the minimal investment required for high-quality insulation tape proves its worth. Without question, it represents not just a tool but a safeguard, a small yet decisive step towards preemptive electrical hazard management. In conclusion, red insulation tape is more than a mere accessory in electrical setups. Its role, verified through years of empirical feedback and expertise, underscores the fine line it helps maintain between safety and hazard. By selecting the right quality and understanding its strategic application, one enhances not just the efficiency but also the reliability of electrical systems. Ensuring the integrity of such seemingly minor components can have a profound impact on overall project outcomes, preserving both personal safety and equipment functionality.

From a technical angle, the ease of application is another element that sets high-quality red insulation tape apart. Users will appreciate the smooth unrolling and effortless tearing, which makes the tape ideal for intricate projects that require precise insulation coverage. Over the years, feedback from both novices and seasoned electricians consistently highlights that a user-friendly product drastically reduces installation time and minimizes errors. Trustworthiness is another critical factor. Red insulation tape serves as an industry standard in distinguishing live wires. In environments shared by multiple trades, such as construction sites, consistent color coding is paramount in maintaining safety standards. The authoritative role of this practice is underscored in electrical regulations globally, reinforcing the tape’s indispensable status on both safety and regulatory fronts. Furthermore, from a cost-efficiency standpoint, red insulation tape serves as an economical solution. Compared to replacement costs and the potential fallout from electrical failures, the minimal investment required for high-quality insulation tape proves its worth. Without question, it represents not just a tool but a safeguard, a small yet decisive step towards preemptive electrical hazard management. In conclusion, red insulation tape is more than a mere accessory in electrical setups. Its role, verified through years of empirical feedback and expertise, underscores the fine line it helps maintain between safety and hazard. By selecting the right quality and understanding its strategic application, one enhances not just the efficiency but also the reliability of electrical systems. Ensuring the integrity of such seemingly minor components can have a profound impact on overall project outcomes, preserving both personal safety and equipment functionality.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025