The Importance of Rubber Insulation Strips in Modern Applications

Rubber insulation strips play a crucial role in various industries, providing essential benefits such as electrical insulation, thermal protection, and mechanical cushioning. These flexible materials are made from synthetic rubber or natural rubber compounds, which boast excellent resistance to heat, moisture, and chemicals, making them an ideal choice for insulation solutions.

Electrical Insulation

One of the primary applications of rubber insulation strips is in electrical systems. These strips serve as barriers to prevent electrical currents from leaking and causing short circuits or electrocution. For instance, in electrical panels, wiring harnesses, and motor housings, rubber insulation strips are used to encase wires and connectors, offering a reliable layer of protection. The versatility of rubber allows it to conform to various shapes and sizes, making it suitable for both custom and standardized applications.

The efficacy of rubber insulation strips in electrical applications is enhanced by their dielectric properties, which ensure that they can withstand high voltages without breaking down. This property is vital in industries such as automotive, aerospace, and telecommunications, where electrical components must maintain functionality under demanding conditions.

Thermal Protection

In addition to electrical insulation, rubber insulation strips provide thermal protection. They help maintain temperature control by reducing heat transfer between surfaces. This quality is particularly beneficial in HVAC systems, refrigeration units, and piping systems. By using rubber insulation strips, companies can improve energy efficiency and minimize heat loss, which ultimately leads to lower operational costs.

The ability of rubber insulation strips to withstand high and low temperatures makes them attractive for applications in extreme environments. They are commonly used in industries such as oil and gas, where machinery operates under significant thermal stress. By implementing proper insulation, these industries can prolong the lifespan of their equipment and ensure safe operation.

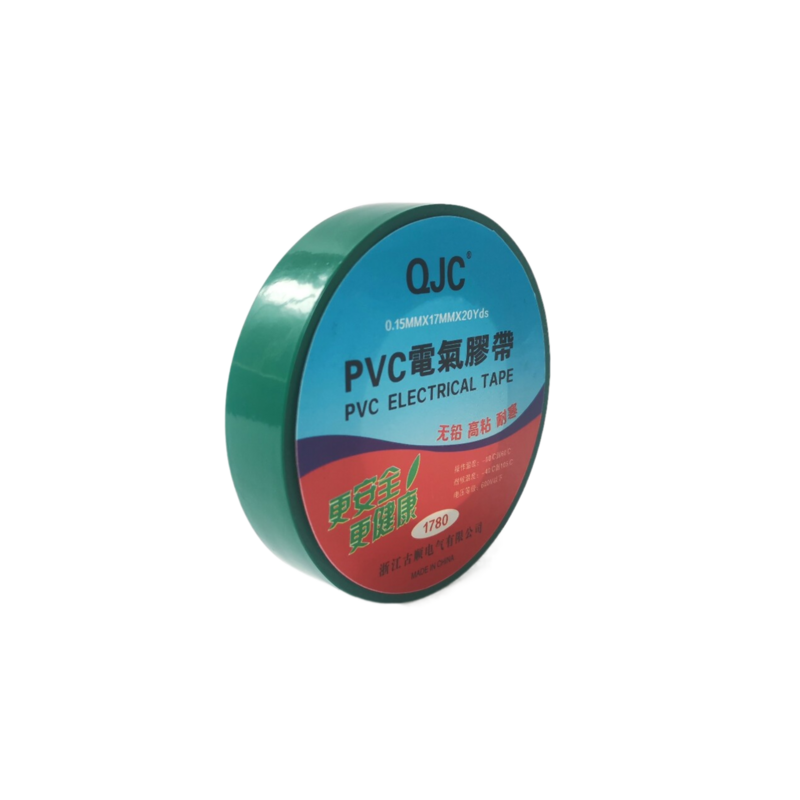

rubber insulation strip

Mechanical Cushioning

Rubber insulation strips also function as mechanical cushioning, dampening vibrations and absorbing shocks. This property is essential in automotive applications, where components experience constant movement and jostle. By incorporating rubber insulation strips in strategic locations, manufacturers can enhance the comfort of ride quality while protecting sensitive parts from damage caused by vibrations.

Furthermore, in construction and building applications, rubber insulation strips are used to reduce noise transmission and vibrations in structures. They are applied in floors, walls, and ceilings to create sound barriers, contributing to a quieter and more comfortable living environment. This noise-reduction quality is particularly appealing in urban areas where sound pollution can be a significant concern.

Environmental Considerations

With the increasing focus on sustainability, the environmental impact of materials used in various applications has come under scrutiny. Fortunately, many manufacturers have adapted their processes to produce eco-friendly rubber insulation strips. These products are made from recycled materials or are labeled as environmentally safe. Choosing sustainable insulation materials not only helps to reduce waste but also appeals to environmentally conscious consumers and businesses.

Conclusion

The significance of rubber insulation strips in modern applications cannot be overstated. They offer a versatile solution for electrical insulation, thermal protection, and mechanical cushioning across various industries. By harnessing the unique properties of rubber, engineers and designers are able to create safer, more efficient, and environmentally friendly products. As technology advances and new materials are developed, rubber insulation strips will continue to play a vital role in ensuring the safety and functionality of electrical and mechanical systems. Investing in high-quality rubber insulation strips is a wise decision for businesses looking to enhance their products while maintaining safety and performance standards.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025