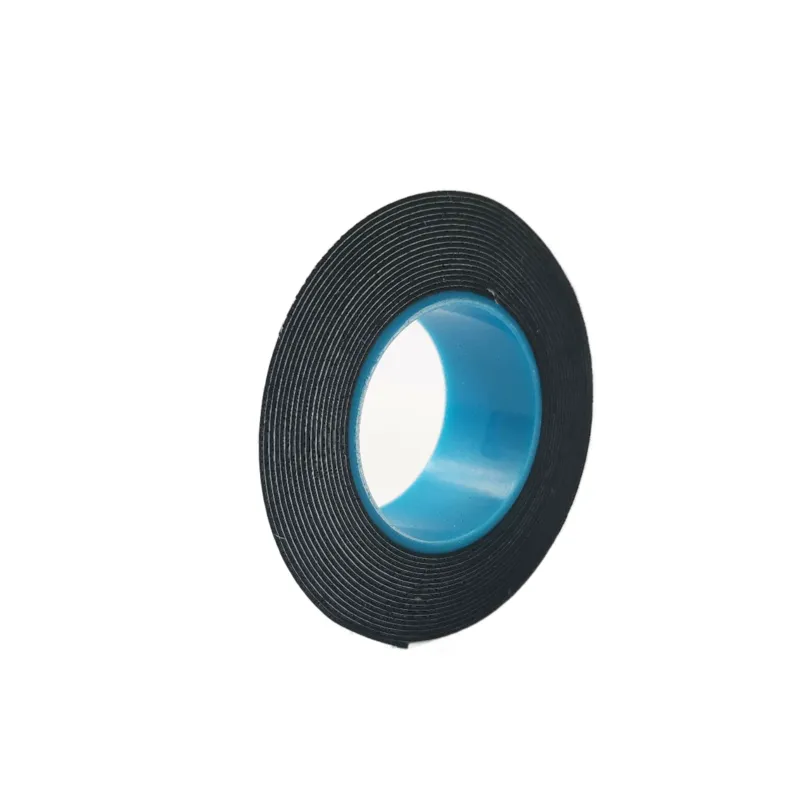

rubber mastic electrical tape

Back to list

Feb . 11, 2025 07:45

Rubber mastic electrical tape has emerged as an essential tool in modern electrical applications, admired for its versatility and reliability. Electricians and technicians continuously seek solutions that guarantee safety, efficiency, and durability. Rubber mastic tape fits this bill perfectly, offering unique characteristics that make it stand out in the industry. Through years of working with this material, the strengths and occasional limitations have become clear, providing invaluable expertise to those looking to enhance their electrical systems.

Environmental considerations have also driven its popularity among green-conscious technicians. Rubber mastic tape does not release harmful toxins into the environment, aligning with sustainability goals. Its durability means less frequent replacements, reducing waste and contributing to a more sustainable practice overall. Customers appreciate the dual benefits of enjoying a superior product while respecting environmental concerns, further underscoring its trustworthiness. Feedback from seasoned electricians highlights the importance of product authenticity. With rubber mastic tape, it's essential to source from reputable manufacturers to ensure quality. Inferior versions might exist in the market, purporting the same benefits but failing under scrutiny. Therefore, aligning purchases with well-known brands or certified suppliers is a common practice to maintain the integrity of electrical projects. To establish authority, it's worth noting industry standards and certifications. Rubber mastic electrical tape often meets IEE, UL, and other internationally recognized safety standards. These certifications are crucial, providing an additional layer of trust and confidence for professionals seeking verified solutions for their electrical needs. Ultimately, as the demand for dependable electrical sealing options grows, rubber mastic electrical tape stands out for its comprehensive benefits. Its unique composition and proven track record make it a preferred choice among professionals. Leveraging such expertise and experience will ensure optimal results, improving not just the longevity of electrical systems but also enhancing safety protocols and reducing environmental impact. As we continue to rely on innovative solutions to power our world, rubber mastic electrical tape undoubtedly plays a crucial role.

Environmental considerations have also driven its popularity among green-conscious technicians. Rubber mastic tape does not release harmful toxins into the environment, aligning with sustainability goals. Its durability means less frequent replacements, reducing waste and contributing to a more sustainable practice overall. Customers appreciate the dual benefits of enjoying a superior product while respecting environmental concerns, further underscoring its trustworthiness. Feedback from seasoned electricians highlights the importance of product authenticity. With rubber mastic tape, it's essential to source from reputable manufacturers to ensure quality. Inferior versions might exist in the market, purporting the same benefits but failing under scrutiny. Therefore, aligning purchases with well-known brands or certified suppliers is a common practice to maintain the integrity of electrical projects. To establish authority, it's worth noting industry standards and certifications. Rubber mastic electrical tape often meets IEE, UL, and other internationally recognized safety standards. These certifications are crucial, providing an additional layer of trust and confidence for professionals seeking verified solutions for their electrical needs. Ultimately, as the demand for dependable electrical sealing options grows, rubber mastic electrical tape stands out for its comprehensive benefits. Its unique composition and proven track record make it a preferred choice among professionals. Leveraging such expertise and experience will ensure optimal results, improving not just the longevity of electrical systems but also enhancing safety protocols and reducing environmental impact. As we continue to rely on innovative solutions to power our world, rubber mastic electrical tape undoubtedly plays a crucial role.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025