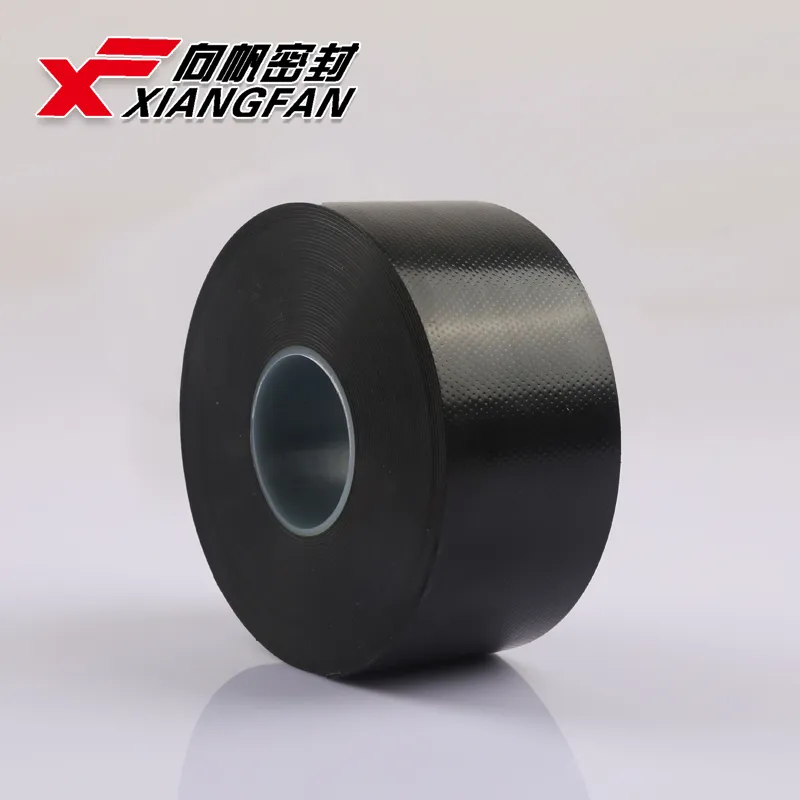

J50 High-voltage EPR Rubber Tape

Back to list

Feb . 10, 2025 20:07

Rubber splicing tape is an essential tool in electrical applications, offering durability, insulation, and protection against environmental factors. This guide explores the efficient use of rubber splicing tape, drawing from professional expertise and practical experience to ensure authoritative advice and build trust with users seeking in-depth understanding.

Final Checks and Maintenance After applying the tape, inspect the wrapped area thoroughly. Look for gaps, uneven spots, or sections where the tape may have loosened. Secure any problematic areas with additional tape as needed. Regular maintenance checks are recommended, particularly in environments with high wear and tear. This proactive approach ensures the splice remains intact and functional over time. Expert Tips Professionals often emphasize the importance of using rubber splicing tape in conjunction with other insulating materials. For added security, follow the rubber tape with a layer of vinyl tape. Vinyl provides additional mechanical protection and helps keep the rubber tape in place, absorbing external impacts that might otherwise cause wear. While self-bonding is a beneficial property, temperature can influence the degree to which the tape bonds. Apply the tape in moderate temperatures for better performance. In cold environments, pre-warming the tape can aid in activation. Safety Considerations Safety is paramount when working with electrical components. Always wear appropriate personal protective equipment (PPE), including gloves and goggles. Ensure the power is off before starting any splicing work to prevent accidents or electrocution. Following industry safety guidelines not only protects you but also ensures the quality of your work. Utilizing rubber splicing tape effectively enhances the safety and durability of electrical systems. Applying this tool correctly ensures long-lasting, reliable connections, whether you're a seasoned electrician or a DIY enthusiast. With experienced application and adherence to safety protocols, rubber splicing tape becomes an invaluable resource in any electrical toolkit.

Final Checks and Maintenance After applying the tape, inspect the wrapped area thoroughly. Look for gaps, uneven spots, or sections where the tape may have loosened. Secure any problematic areas with additional tape as needed. Regular maintenance checks are recommended, particularly in environments with high wear and tear. This proactive approach ensures the splice remains intact and functional over time. Expert Tips Professionals often emphasize the importance of using rubber splicing tape in conjunction with other insulating materials. For added security, follow the rubber tape with a layer of vinyl tape. Vinyl provides additional mechanical protection and helps keep the rubber tape in place, absorbing external impacts that might otherwise cause wear. While self-bonding is a beneficial property, temperature can influence the degree to which the tape bonds. Apply the tape in moderate temperatures for better performance. In cold environments, pre-warming the tape can aid in activation. Safety Considerations Safety is paramount when working with electrical components. Always wear appropriate personal protective equipment (PPE), including gloves and goggles. Ensure the power is off before starting any splicing work to prevent accidents or electrocution. Following industry safety guidelines not only protects you but also ensures the quality of your work. Utilizing rubber splicing tape effectively enhances the safety and durability of electrical systems. Applying this tool correctly ensures long-lasting, reliable connections, whether you're a seasoned electrician or a DIY enthusiast. With experienced application and adherence to safety protocols, rubber splicing tape becomes an invaluable resource in any electrical toolkit.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025