Exploring the World of Rubber Tape Manufacturing

Rubber tape, an essential product in various industries, plays an important role in both commercial and residential applications. The manufacturing of rubber tape is an intricate process that combines advanced technology with traditional craftsmanship. This article delves into the fascinating world of rubber tape factories, exploring their operations, the manufacturing process, and the diverse applications of rubber tape.

Exploring the World of Rubber Tape Manufacturing

The next step in the manufacturing process involves the extrusion of rubber into tape form. This is achieved using advanced machinery that shapes the rubber into long, thin strips. The temperature and pressure during extrusion are meticulously controlled to ensure uniformity and quality. After extrusion, the tape is cut into various lengths, depending on the specifications required by customers.

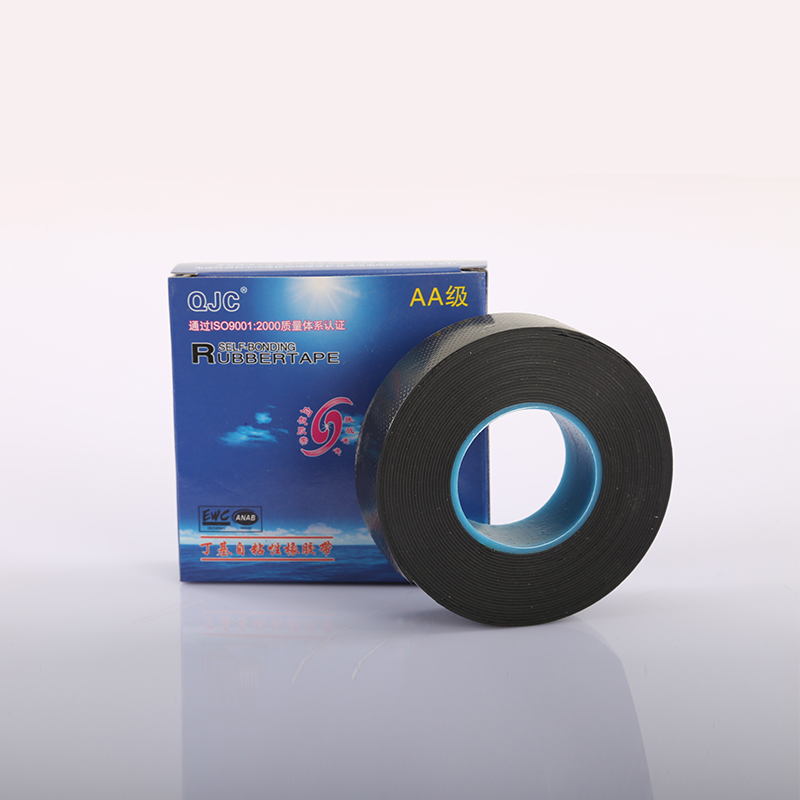

rubber tape factory

Curing is a crucial step that transforms the raw rubber into a strong, durable material. This process, often referred to as vulcanization, involves heating the rubber with sulfur to create cross-links between polymer chains. This chemical reaction strengthens the rubber, enhancing its elasticity and durability. Once cured, the rubber tape undergoes a thorough inspection to guarantee it meets the desired quality standards.

Rubber tape finds its applications in numerous fields, including electrical, automotive, plumbing, and construction industries. It serves as an excellent insulating material, providing protection against moisture, chemicals, and environmental factors. In electrical applications, rubber tape is widely used for insulating and protecting wires, ensuring safety and reliability. Additionally, its adhesive properties make it an ideal choice for sealing and repair tasks in both industrial and consumer settings.

The growing demand for sustainable products has also influenced the rubber tape manufacturing industry. Many factories are now adopting eco-friendly practices, such as using recycled materials and implementing energy-efficient processes. These initiatives not only help reduce the environmental footprint but also create a more sustainable supply chain.

In conclusion, rubber tape factories play a vital role in producing a versatile and indispensable product. Through meticulous manufacturing processes and a focus on quality, these factories supply industries with reliable solutions that meet their diverse needs. As technology advances and consumer demands evolve, the rubber tape industry is poised for continued growth, innovation, and sustainability.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025